Use of sodium carbonate as fired fly ash brick blank plasticizer

A technology of fly ash bricks and sodium carbonate, which is applied in the field of sodium carbonate as a plasticizer for sintered fly ash brick blanks, sodium carbonate, and can solve the problem of little research on plasticizers

Inactive Publication Date: 2009-11-25

HARBIN INST OF TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But at present, there are few studies on plas

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

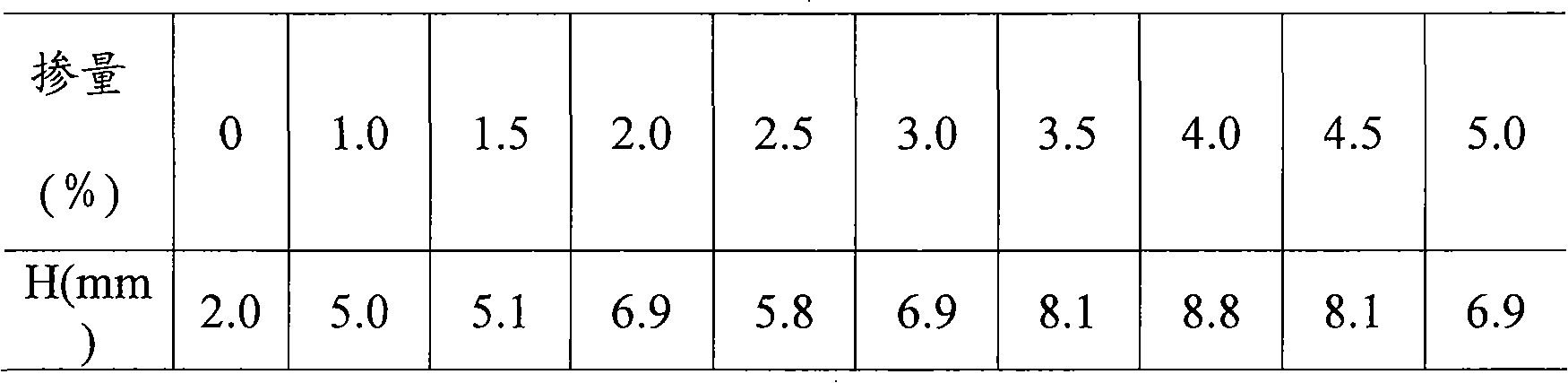

The invention discloses a use of sodium carbonate as fired fly ash brick blank plasticizer and belongs to field of building materials. Experiments find that sodium carbonate can be used as fired fly ash brick blank plasticizer for preparing fired fly ash brick. Mixture of sodium carbonate and fly ash is blended by weight ratio of 3.5-4.5:96.5-95.5 and plasticizing effect is good. Sodium carbonate is used as fired fly ash brick blank plasticizer for preparing fired fly ash brick with low cost, good plasticizing effect and no influence on molding of admixture.

Description

technical field [0001] The invention relates to a new application of sodium carbonate, in particular to the application of sodium carbonate as a plasticizer for sintered fly ash brick blanks, and belongs to the field of building materials. Background technique [0002] From June 1, 2000, some coastal cities and cities with insufficient land resources have banned the use of clay bricks, and restricted the production and use of other clay products according to conditions. Cities such as Beijing and Shanghai banned the use of ordinary clay bricks in January 2000. At present, the country has identified 170 large and medium-sized cities to restrict the ban on clay bricks. [0003] "2009-2012 China's New Building Materials Industry Investment Analysis and Prospect Forecast Report" pointed out: In recent years, China's wall material innovation and promotion of energy-saving buildings have made positive progress. In 2006, the national output of new wall materials reached 385 billio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B22/10C04B103/30

Inventor 赵亚丁崔金江李学英

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com