Lead frame of IPM module

A lead frame, lead frame technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as inability to completely overcome, unclean removal, increase labor costs, etc., to solve the residual plastic packaging material, reduce contact area, save The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

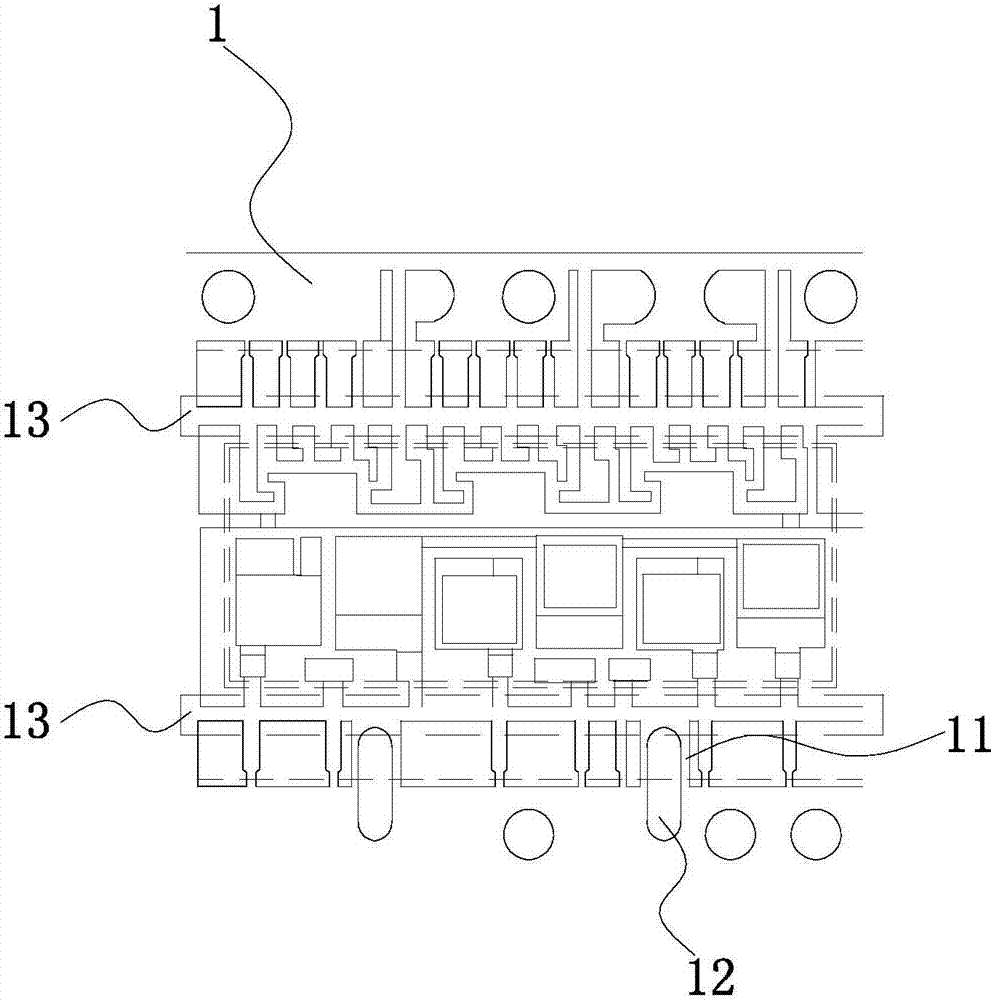

[0021] Such as figure 1 As shown, the present invention discloses a lead frame of an IPM module, which includes a lead frame panel 1 and a feed channel 11 arranged on the lead frame panel 1 . At least one through hole 12 is opened on the feeding channel 11 .

[0022] A through hole 12 is provided in the feeding channel 11 so that the molding compound remaining in the through hole 12 is easily and automatically removed after the feeding is completed, and will not remain on the feeding channel 11 . At the same time, the molding compound carried on the feeding channel 11 is reduced, thereby effectively reducing the contact area between the molding compound and the lead frame, and reducing the adhesive force between the molding compound and the lead frame at this position. The invention does not need to modify the process of the existing equipment, which saves the production cost; it does not need to change the type of plastic sealing compound, and avoids the impact on product qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com