Method for measuring temperature of high-voltage/extra-high-voltage cable connector by using fiber

A cable joint and optical fiber measurement technology, which is applied to the real-time online monitoring of the working temperature of UHV cable joints, in the high-voltage field, can solve problems such as hidden dangers of insulation, difficulties in installation and maintenance of optical fibers, etc., achieve beautiful appearance, reduce the difficulty of fixing, and reduce installation costs the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

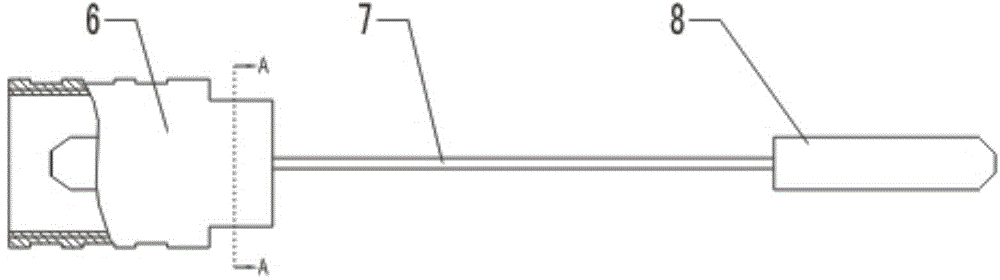

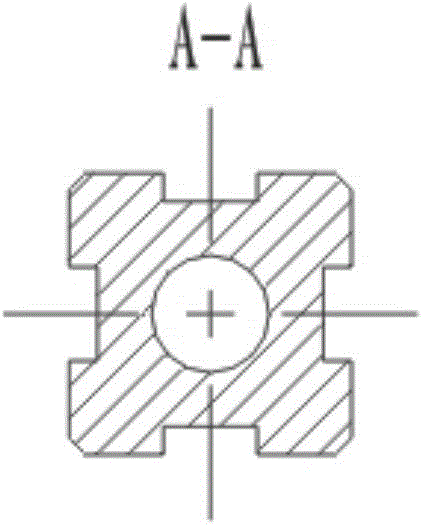

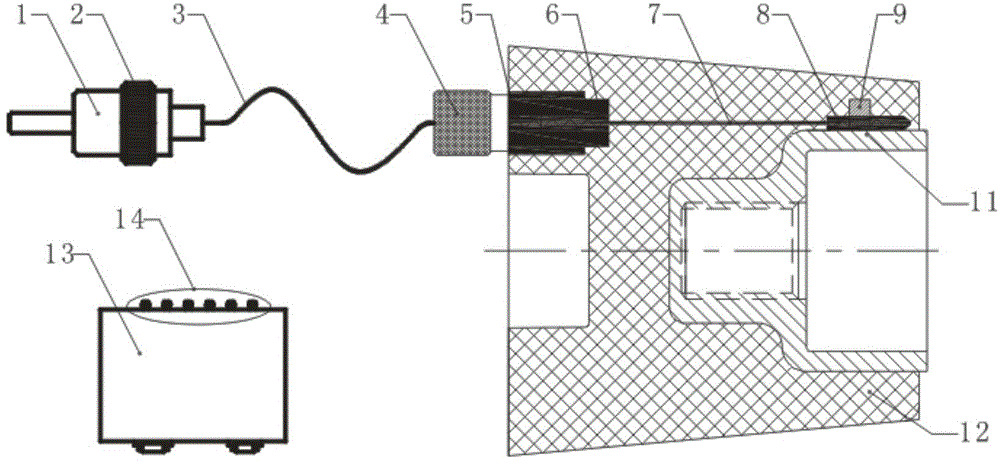

[0011] Example: such as image 3 Shown is a method for measuring the temperature of high-voltage and ultra-high-voltage cable joints with optical fibers, which includes an external temperature-measuring optical fiber 1 , an internal temperature-measuring optical fiber 5 , a temperature-measuring probe fixing fixture 9 and a temperature demodulator 13 . like figure 1 , figure 2 , Figure 4 As shown, the internal temperature-measuring optical fiber 5 includes an adapter insert 6 , an internal optical fiber 7 and a temperature-measuring probe 8 connected in sequence. The surface of the connecting insert 6 is provided with an annular groove and a square flat body. The internal temperature-measuring optical fiber 5 is pre-embedded in the cable plug 12 by casting, and the annular groove and the square flat body prevent the connecting insert 6 from moving axially or radially. Use the temperature measuring probe fixing fixture 9 to fix the temperature measuring probe 8 on the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com