Cattle TMR(Total Mixed Ration) granulated biological feed and preparation method thereof

A technology of biological feed and granules, which is applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of shortage of high-quality roughage resources, mold pollution safety of silage and bulk TMR diets, and high breeding costs, so as to improve digestion and utilization rate, increase the digestibility of the diet, and prolong the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

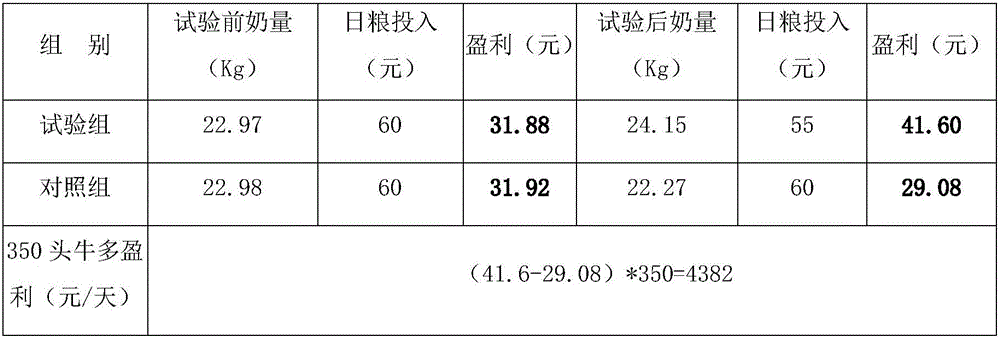

Image

Examples

Embodiment 1

[0026] Embodiment 1: bovine TMR particle biological feed, it comprises the component of following parts by weight: 14 parts of corn, 4 parts of cereal by-products, 2 parts of soybean meal, 2 parts of miscellaneous meal, 4 parts of DDGS, 0.5 part of stone powder, 0.1 part of calcium hydrogen phosphate 0.3 parts of salt, 0.3 parts of baking soda, 0.05 parts of magnesium oxide, 0.05 parts of multi-vitamins, 0.05 parts of multi-minerals, 2 parts of biological fermentation materials, 10 parts of soybean hulls, 10 parts of cottonseed hulls, 5 parts of grass, 2 parts of adhesive. Among them, the grain by-products are corn spraying, fiber husk, rice husk, etc., and the binders are specifically secondary flour, bentonite, etc. The moisture content of the biological fermentation material is not more than 40%, the mass percentage of crude protein is not less than 14%, the mass percentage of crude ash is not more than 8%, and the total number of beneficial bacteria is not less than 5.0x10...

Embodiment 2

[0027] Embodiment 2: the preparation method of embodiment 1 cattle TMR granular biological feed, it comprises the steps: (1) raw material cutting, pulverizing; (2) raw material is weighed and mixed; (3) low temperature granulation; Wherein,

[0028](1) Cutting and crushing of raw materials: corn, grain by-products, soybean meal, miscellaneous meal and DDGS are crushed separately, and the crushing particle size is controlled at 100% to pass through an 8-mesh sieve; the grass is cut, and the cutting length is controlled at 10mm; the soybean skin is crushed, The crushing particle size is sieved with a sieve with an aperture of 1.18mm, and the weight percentage of the sieve is 20%; the cottonseed husk is crushed, and the crushed particle size is sieved with a sieve with an aperture of 5mm, and the weight percentage of the sieve is 60%;

[0029] (2) Weighing and mixing of raw materials: Weigh 14 parts of crushed corn, 4 parts of cereal by-products after crushing, 2 parts of soybean ...

Embodiment 3

[0035] Embodiment 3: bovine TMR particle biological feed, it comprises the component of following parts by weight: 35 parts of corns, 15 parts of cereal by-products, 15 parts of soybean meal, 10 parts of miscellaneous meal, 15 parts of DDGS, 1.5 parts of stone powder, 0.5 parts of calcium hydrogen phosphate 1 part of salt, 1.5 parts of baking soda, 0.2 parts of magnesium oxide, 0.2 parts of multi-vitamins, 0.2 parts of multi-minerals, 10 parts of biological fermentation material, 20 parts of bean skin, 20 parts of cottonseed hull, 20 parts of grass, sticky Mixture 5 parts. Among them, the grain by-products are corn spraying, fiber husk, rice husk, etc., and the binders are specifically secondary flour, bentonite, etc. The moisture content of the biological fermentation material is not more than 40%, the mass percentage of crude protein is not less than 14%, the mass percentage of crude ash is not more than 8%, and the total number of beneficial bacteria is not less than 5.0x10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com