Heat insulation layer for realization of temperature gradient of rutting test specimen

A technology of temperature gradient and heat insulation layer, which is applied to the design of the external heat insulation layer realized by the temperature gradient of asphalt mixture specimens, and the field of heat insulation layer to realize the temperature gradient of rutting specimens, which can solve waste, complicated operation, and heat insulation design Insufficient heat insulation effect and other problems, to achieve the effect of convenient production, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

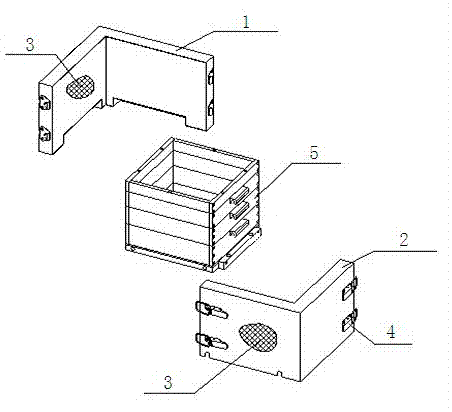

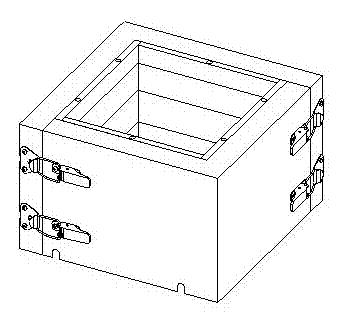

[0023] A heat insulation layer to realize the temperature gradient of the rutting specimen, including two independent and combinable parts, the left heat insulation layer and the right heat insulation layer, both of which are "V" composed of two mutually perpendicular cuboids font structure;

[0024] The conditions for the size of the left heat insulation layer and the right heat insulation layer are: the two can just be combined to form a seamless "back"-shaped combination, and the inner wall cross-section and outer wall cross-section of the combination are both square; It can be fixedly connected by a tool buckle; the side length and width of the cross-section of the inner wall of the combination are equal to the side length of the cross-section of the outer wall of the test mold, and the height is equal to the height of the test mold;

[0025] Both the left heat insulation layer and the right heat insulation layer are composed of an outer shell and an insulation layer used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com