New technology of spandex fiber

A new process and spinning technology, which is applied in the field of dry spinning process, can solve the problems of low production efficiency of single machine, high cost per unit output, and small number of spinnerets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

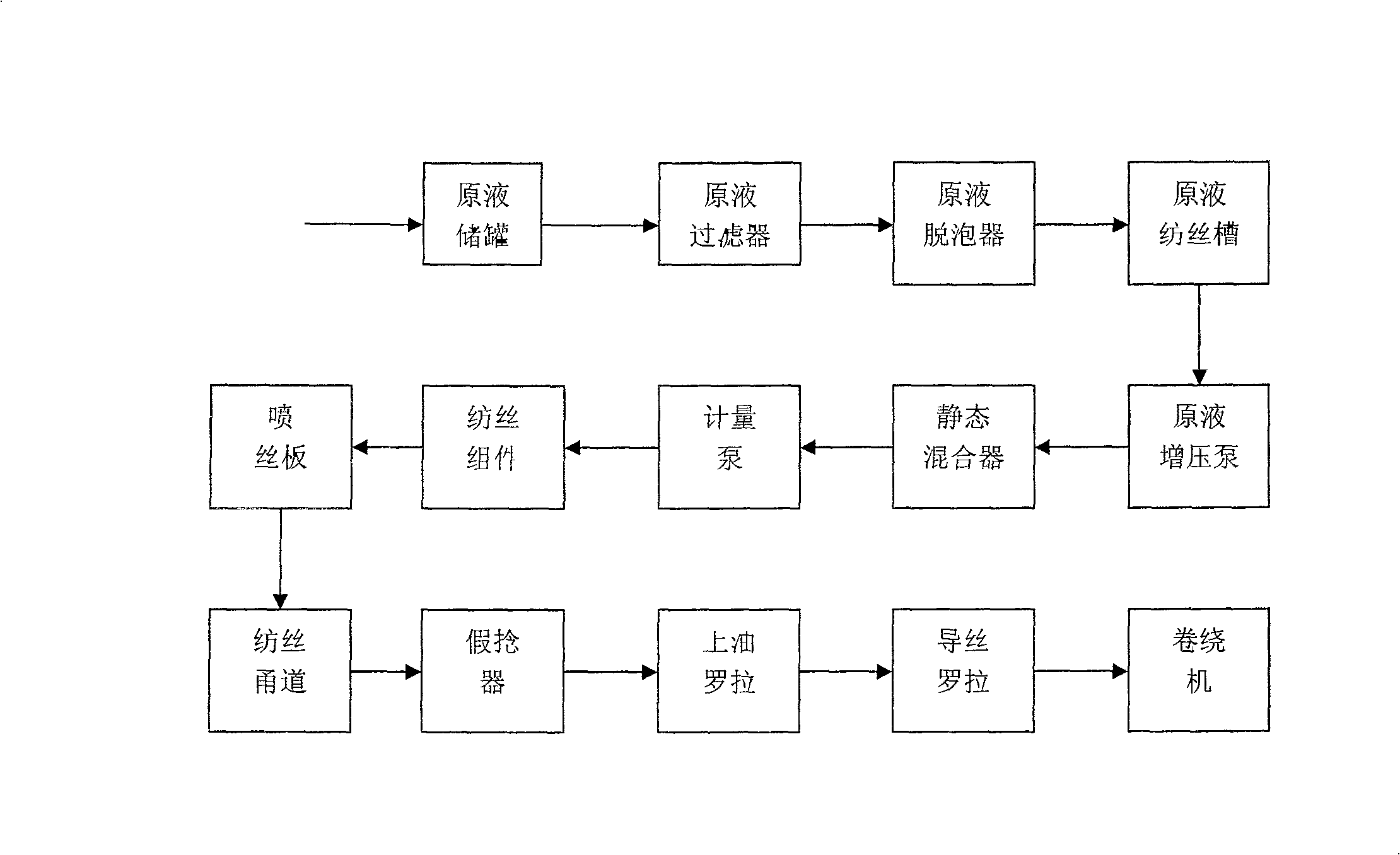

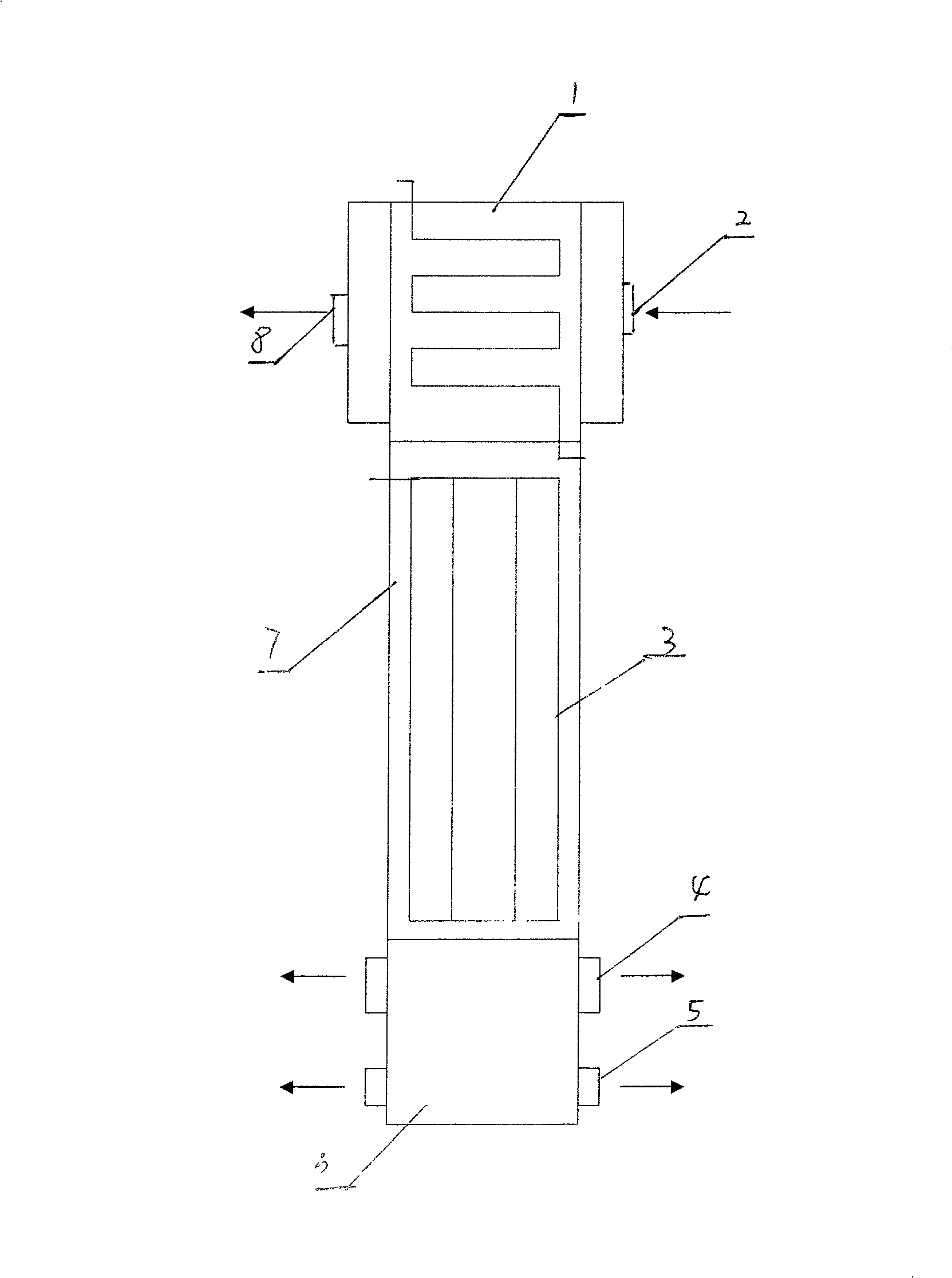

[0012] Spandex production is mainly divided into processes such as polymerization, spinning winding and post-treatment, and current spinning method has four kinds: dry spinning, wet spinning, melt spinning and reaction spinning, spinning of the present invention The new process is 32 dry spinning. The stock solution after the polymerization reaction is transferred to the storage tank, stored and matured, then filtered, defoamed, and then enters the spinning tank, is fed by nitrogen pressure, pressurized by the gear pump, enters the spiral vane static mixer, and spits out the stock solution through the metering pump in the spinning tank. The filament assembly is filtered, distributed to the spinneret and sprayed out. The pressure in front of the metering pump is increased to 15-20kg / cm2. After the solvent is evaporated and removed in the spinning tunnel, it is solidified into spandex tow, and then false twisted, Oil it, and wind it into a certain weight silk roll on the winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com