Manufacturing method of spandex heavy denier yarn

A technology of coarse denier and spandex, which is applied in the manufacturing field of spandex coarse denier yarn, which can solve the problems of poor resilience, low added value of products, false twist, etc., and achieve the effect of excellent resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

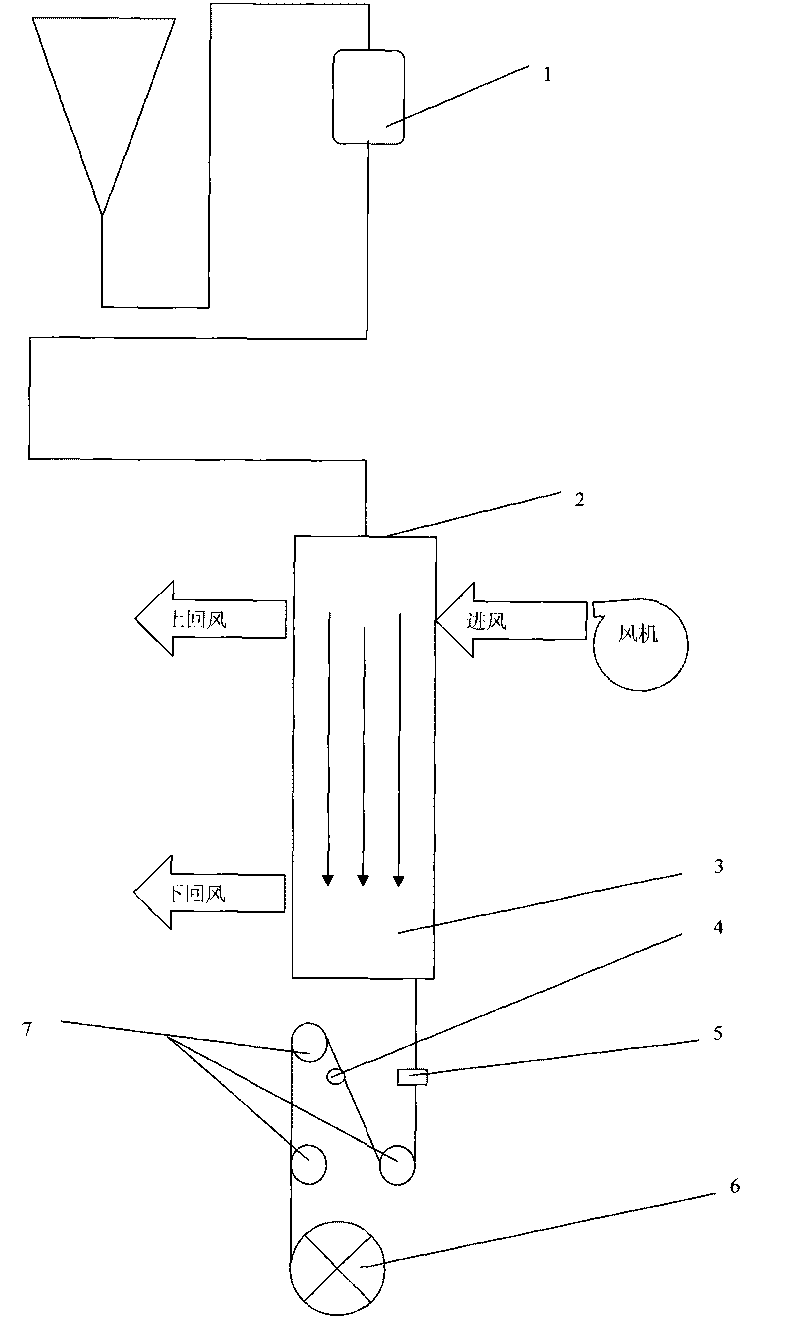

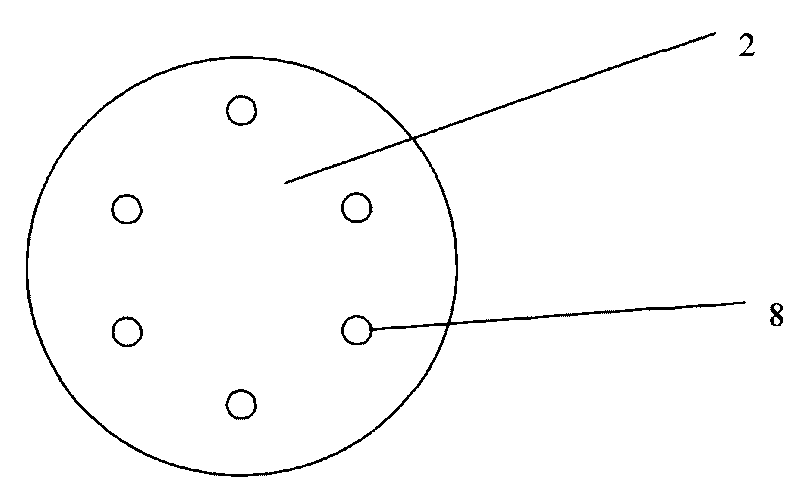

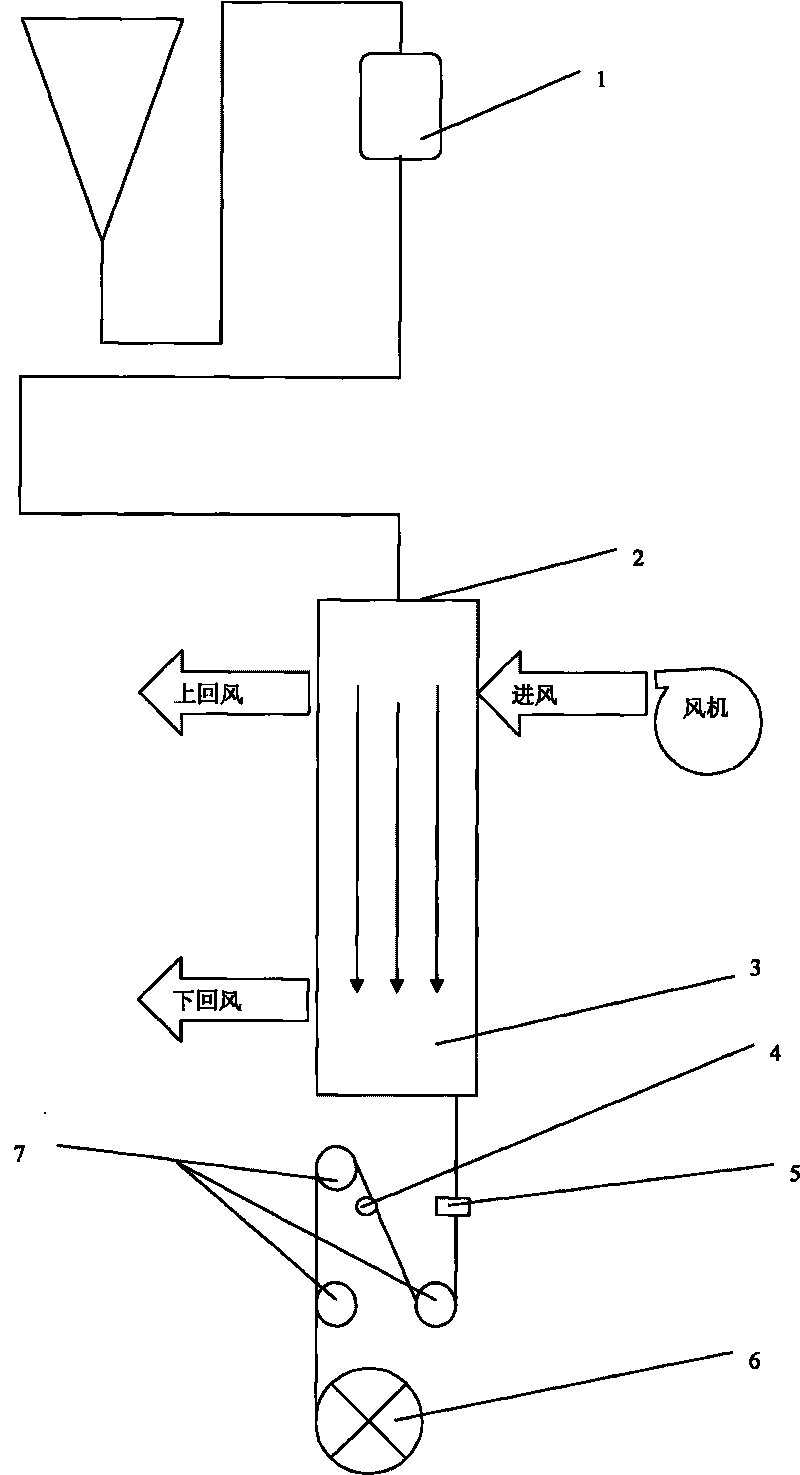

Method used

Image

Examples

Embodiment 1

[0022] Add 400kg of polytetramethylene ether glycol (PTG) and 100kg of diphenylmethane-4.4'diisocyanate (MDI) raw materials into the reactor respectively, mix at 47°C, and after 1 hour, make The temperature reached 65°C and was maintained at reaction temperature for 2 hours. At this point the prepolymerization reaction is substantially complete. Then the reactant enters the cooling zone where the cooling water passes through the jacket, and is cooled to 36° C. for 3.5 hours. After cooling, a prepolymer is obtained, and dimethylacetamide is added to dissolve the prepolymer. The prepolymer solution is delivered to the storage tank, where the prepolymer solution stays for 8 hours.

[0023] Secondly, the prepolymer solution and the 5% mixed amine solution containing 90% ethylenediamine, 8% propylenediamine, and 2% diethylamine are continuously added at a rate of 500Kg / h and 200Kg / h respectively. The reaction was carried out in a dynamic mixer with a rotating speed of 300 rpm, th...

Embodiment 2

[0026] First, add 400kg of polytetramethylene ether glycol (PTG) and 100kg of diphenylmethane-4.4'-diisocyanate (MDI) raw materials into the reactor respectively, and mix them at 47°C. After 1 hour, The temperature was brought to 65°C and maintained at reaction temperature for 2.5 hours. At this point the prepolymerization reaction is substantially complete. Then the reactant enters the cooling zone where cooling water passes through the jacket, and is cooled to 38° C. for 3 hours. After cooling, a prepolymer is obtained, and dimethylacetamide is added to dissolve the prepolymer. The prepolymer solution is delivered to the storage tank, where the prepolymer solution stays for 8 hours.

[0027] Secondly, the prepolymer solution and the 5% mixed amine solution containing 90% ethylenediamine, 8% propylenediamine, and 2% diethylamine are continuously added at a rate of 500Kg / h and 200Kg / h respectively. The reaction was carried out in a dynamic mixer with a rotational speed of 50...

Embodiment 3

[0030] First, 400kg of polytetramethylene ether glycol (PTG) and 100kg of diphenylmethane-4.4'diisocyanate (MDI) raw materials were added to the reactor respectively, and mixed at 47°C. After 1 hour, The temperature was brought to 65°C and maintained at reaction temperature for 3 hours. At this point the prepolymerization reaction is substantially complete. Then the reactant enters the cooling zone through the cooling water in the jacket, and is cooled to 40° C. for 2.5 hours. After cooling, the prepolymer is obtained, and dimethylacetamide is added to dissolve the prepolymer. The prepolymer solution is delivered to the storage tank, where the prepolymer solution stays for 8 hours.

[0031] Secondly, the prepolymer solution and the 5% solution containing 90% ethylenediamine, 8% propylenediamine, and 2% diethylamine are continuously added at a speed of 500Kg / h and 200Kg / h respectively, and the rotation speed is 700rpm The reaction was carried out in a dynamic mixer, the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com