Ceramic piece, USB socket connector and formation method of USB socket connector

A socket connector, ceramic parts technology, applied in the direction of two-part connection device, connection, and components of the connection device, etc., can solve the problems affecting the application function and service life of the USB socket connector, poor ceramic toughness, easy to break, etc. , to ensure the normal application function, reduce the degree of deformation, strengthen the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

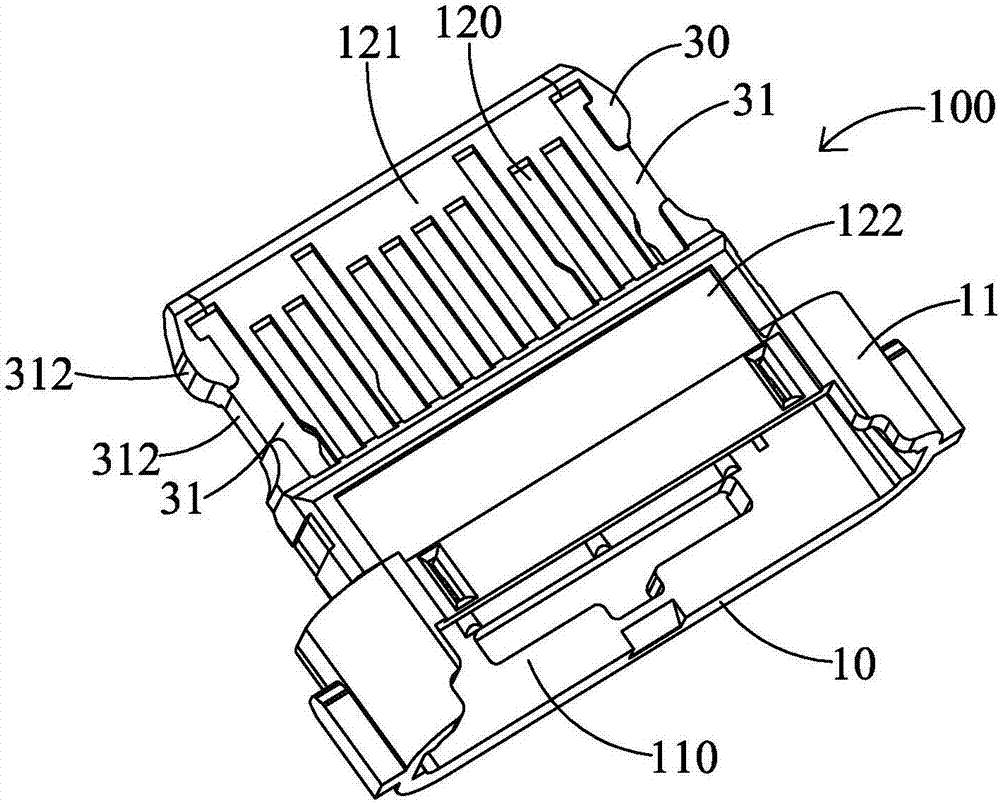

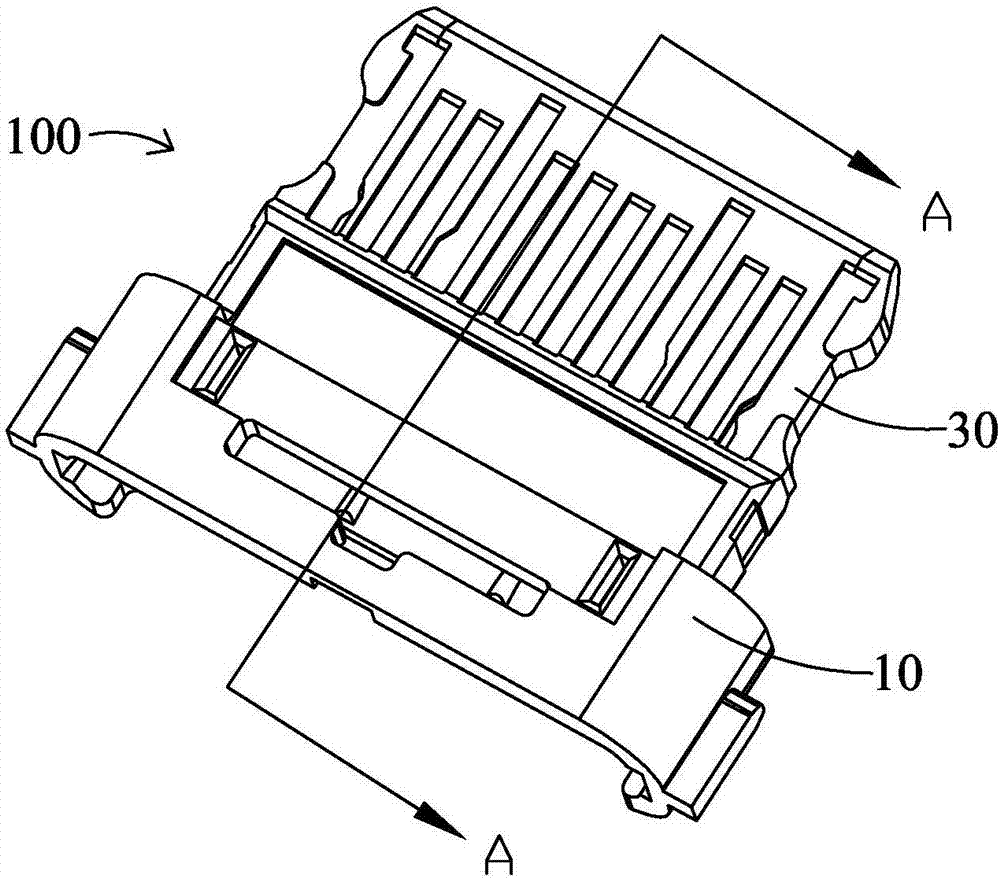

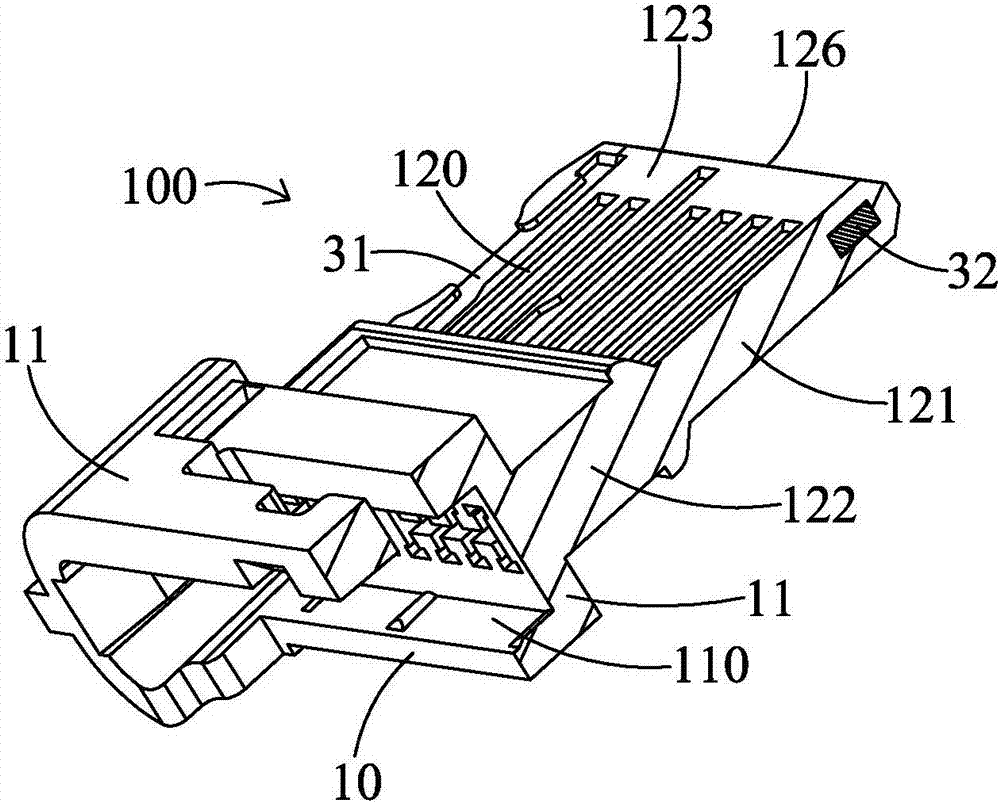

[0027] refer to Figure 1 to Figure 7 As shown, the USB receptacle connector 100 of the present invention is a USB TYPE-C receptacle connector, which is used to be installed on a circuit board for insertion of a USB plug connector (not shown), and the USB plug connector is provided with a metal lock Buckle piece, the USB receptacle connector 100 includes an insulating body 10, an insulating block 20, a ceramic part 30, two sets of conductive terminals 40 and a metal shell (not shown) for accommodating the insulating body 10, and the insulating block 20 is injection-molded on the conductive terminals 40 is defined as a terminal module.

[0028] The insulating body 10 includes a main body 11 and first and second abutting portions 121, 122 protruding forward from the main body 11. The first abutting portion 121 protrudes forward from the center of the second abutting portion 122, and the second abutting portion 122 connects the main body 11 and the first docking portion 121 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com