Steel pipe-straightening roller for casting high chromium iron or high chrome steel

A straightening roll and high-chromium iron technology, which is applied in the field of casting high-chromium iron or casting high-chromium steel steel pipe straightening rolls, can solve the problems of limited hardened layer of forging straightening rolls, and overcome the limited hardened layer and process. The effect of less and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

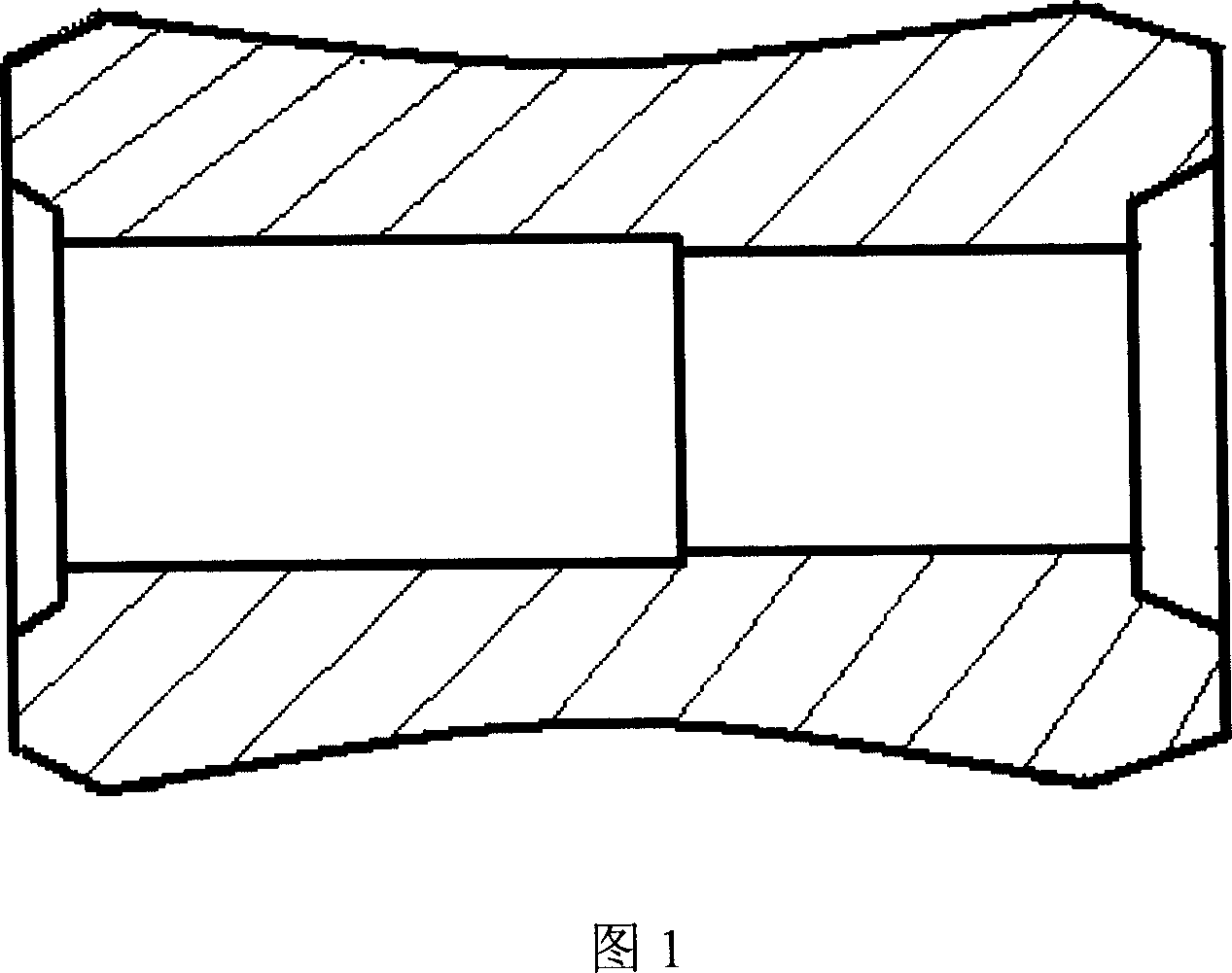

Image

Examples

Embodiment 1

[0038] Manufacture a set of steel pipe straightening rolls in hot straightening state for Φ250 seamless steel pipe continuous rolling mill, a total of 6 pieces. The composition range of selected cast high chromium iron is as follows (unit is weight percentage):

[0039] C

Si

mn

P

S

Cr

Ni

Mo

V

Cu

2.8

≤1.0

≤1.0

≤0.04

≤0.04

22

1.5

2.0

0.2

0.5

[0040] Add rare earth element RE: 0.01%, the rest is Fe.

[0041] Select the ratio of raw materials according to the composition requirements, carry out conventional smelting in an intermediate frequency induction furnace, and perform conventional sand casting to obtain the required blank, and then perform conventional processing such as turning and grinding to produce Φ250 seamless steel pipes for continuous rolling mills. Straightening state with steel pipe straightening rollers.

[0042] The steel pipe str...

Embodiment 2

[0044] Manufacture a set of steel pipe straightening rolls for φ180 seamless steel pipe continuous rolling mill, 6 pieces in total. The composition range of selected cast high chromium iron grades is as follows.

[0045] C

Si

mn

P

S

Cr

Ni

Mo

V

Cu

1.8

≤1.0

≤1.0

≤0.04

≤0.04

12

0.5

0.8

0.2

0.8

[0046] Add rare earth RE: 0.02%, the rest is Fe.

[0047] According to the composition requirements, the ratio of raw materials is selected, conventional melting is carried out in an intermediate frequency induction furnace, and conventional sand casting is carried out to obtain the required blank, and then conventional heat treatment and processing such as turning and grinding are carried out to produce a φ180 seamless steel pipe continuous rolling unit Straighten the rolls with steel pipes.

[0048] The φ 180 seamless steel tube con...

Embodiment 3

[0050] In this embodiment, according to the application of cast high chromium iron or cast high chromium steel steel pipe straightening rolls in the present invention to a steel pipe straightening machine, a set of 10 pieces of Φ140 seamless steel pipes are fully floating and continuously rolled by casting production technology. Steel pipe straightening rollers in hot straightening state for the unit, the composition of which is selected from the following high-chromium iron composition (by weight percentage):

[0051] C

Si

mn

P

S

Cr

Ni

Mo

V

Cu

2.3

≤1.0

≤1.0

≤0.04

≤0.04

16

1.2

1.2

0.4

0.2

[0052] Add rare earth RE: 0.2%, the rest is Fe.

[0053] Select the raw material ratio according to the composition requirements, melt and cast in the medium frequency induction furnace to obtain the required blank, and then perform heat treatment, tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com