Method for improving ink adhesion in plastic printing product

A print and adhesion technology, applied in the direction of ink, metal material coating process, ion implantation plating, etc., can solve the problems of high requirements for operators and machinery and equipment, difficult to control the degree of reaction, and poor printing effect, etc., to achieve Increase color fixation, overcome small dielectric constant, and increase smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

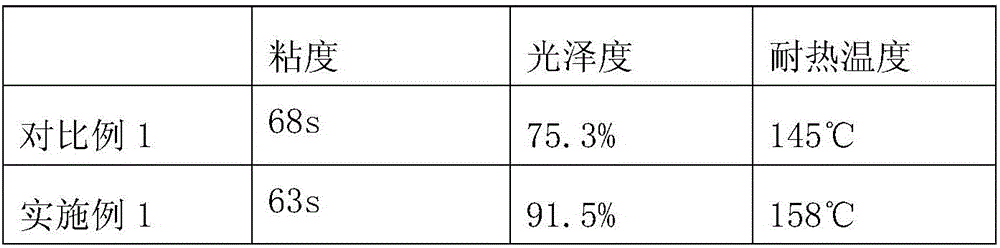

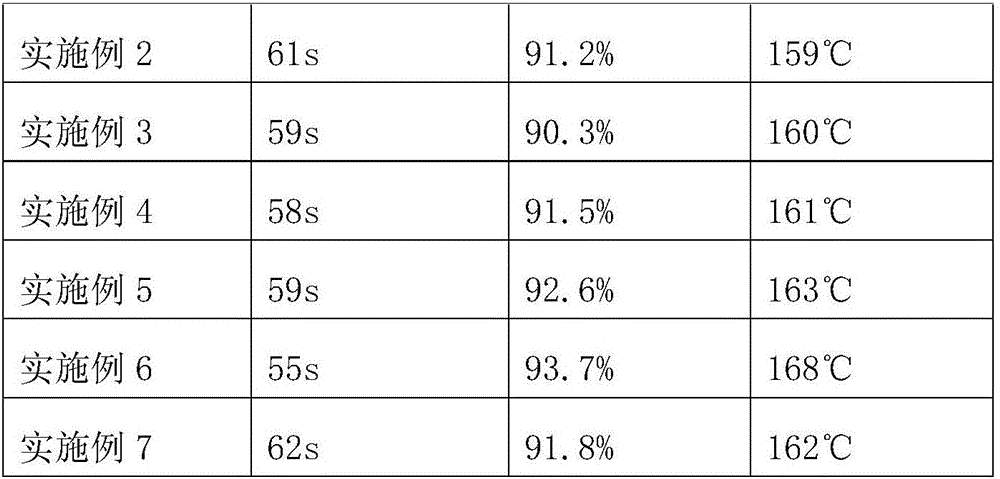

Examples

Embodiment 1

[0051] A method for improving ink adhesion in plastic printed matter, comprising the steps of:

[0052] (1) Pretreatment of plastic products: put phenolic resin products into 10% hydrochloric acid solution by mass fraction and soak for 2 hours, then wash with deionized water, soak in 75% ethanol solution for 5 minutes, and use nitrogen gas Blow dry, put it into the magnetron sputtering equipment quickly, and fill it with nitrogen-oxygen mixed gas after vacuuming, wherein the volume content of oxygen is 60%. Inject mixed gas ions for 15 minutes to obtain plastic crude products;

[0053] (2) Printing: Install the plastic rough product on the printing equipment, then spray ink on the printing plate, and then move the pad printing head through the mechanical arm to shift the predetermined position of the printing plate on the plastic rough product, in the infrared drying box Dry at 55°C for 2 hours to obtain the finished product;

[0054] The ink is made from the following compo...

Embodiment 2

[0056] A method for improving ink adhesion in plastic printed matter, comprising the steps of:

[0057] (1) Pretreatment of plastic products: soak aminoplastic products in a hydrochloric acid solution with a mass fraction of 12% for 3 hours, then wash with deionized water, soak in an ethanol solution with a mass fraction of 78% for 8 minutes, and use nitrogen gas Blow dry, put it into the magnetron sputtering equipment quickly, fill it with helium-oxygen mixed gas after vacuuming, wherein the volume content of oxygen is 80%, under the condition that the radio frequency frequency is 12MHz and the sputtering voltage is 0.5kV, Sputter mixed gas ions for 20 minutes to obtain plastic crude products;

[0058] (2) Printing: Install the plastic rough product on the printing equipment, then spray ink on the printing plate, and then move the pad printing head through the mechanical arm to shift the predetermined position of the printing plate on the plastic rough product, in the infrare...

Embodiment 3

[0061] A method for improving ink adhesion in plastic printed matter, comprising the steps of:

[0062] (1) Pretreatment of plastic products: put the polyvinyl chloride product into a hydrochloric acid solution with a mass fraction of 13%, soak it for 2.5h, then wash it with deionized water, and soak it in an ethanol solution with a mass fraction of 78% for 6min , blow dry with nitrogen, put it into the magnetron sputtering equipment quickly, and fill it with xenon-oxygen mixed gas after vacuuming. Next, sputter mixed gas ions for 17 minutes to obtain plastic crude products;

[0063] (2) Printing: Install the plastic rough product on the printing equipment, then spray ink on the printing plate, and then move the pad printing head through the mechanical arm to shift the predetermined position of the printing plate on the plastic rough product, in the infrared drying box Dry at 65°C for 3 hours to obtain the finished product;

[0064] The ink is made from the following compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com