Vision-based automatic aviation oil mist nozzle atomization angle detection device and method

An automatic detection device, oil mist nozzle technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large randomness, not fully utilizing the atomization edge, and low accuracy, so as to improve accuracy and human The effect of friendly machine interaction and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the examples.

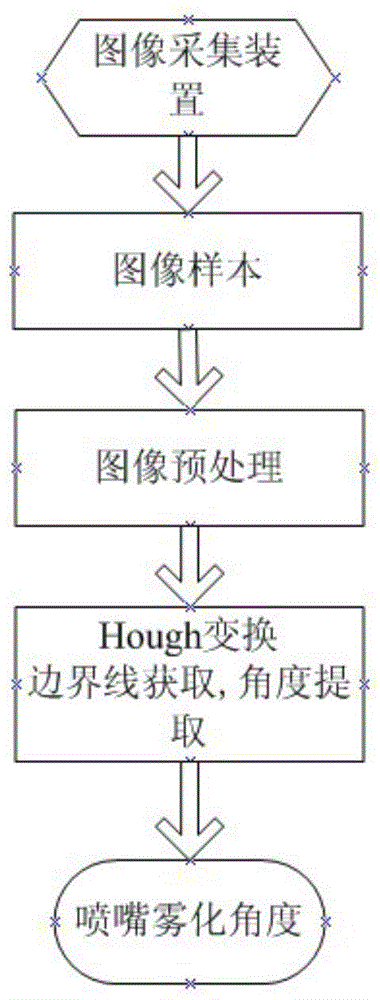

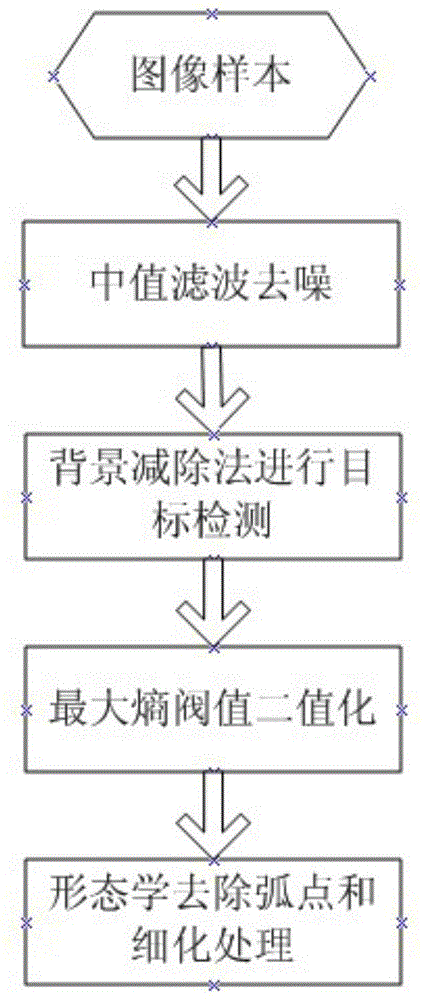

[0025] The technical scheme adopted in the present invention is: utilize image acquisition device to obtain digital image, write image processing algorithm based on Labview software development platform to carry out enhancement, edge detection, binarization to the collected image, remove arc point and thinning and other preprocessing, The two boundary lines of the spray cone angle are obtained by Hough transform in pattern recognition, and finally the atomization cone angle of the nozzle is calculated. The angle value is displayed on the man-machine interface.

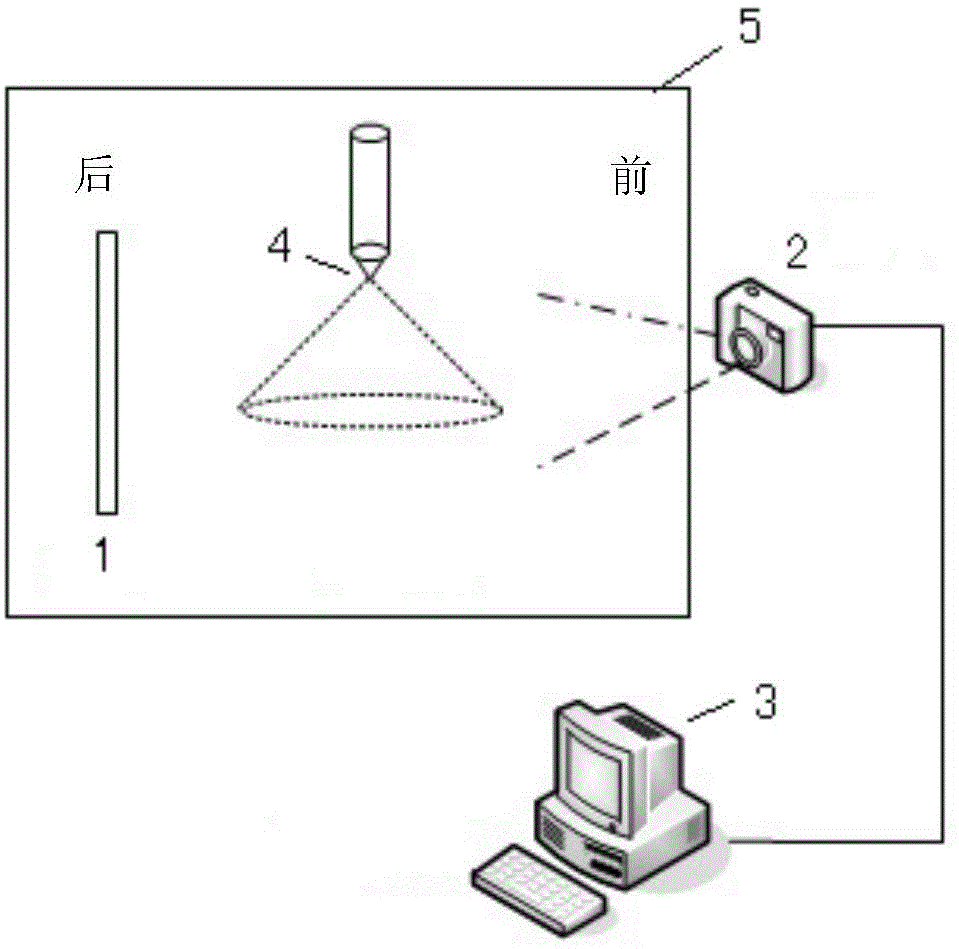

[0026] Such as figure 1 As shown, the image acquisition device is composed of an industrial camera 2 and its internal digital I / O trigger interface card, a light source 1, and an explosion-proof industrial computer 3. The industrial camera 2 accepts an external trigger signal, takes an image, and when the shooti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com