Method for producing bamboo-wood composite board

A production method and technology of composite boards, applied in the jointing of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve problems such as large warping deformation, low static bending strength, and affecting product market development, and achieve growth cycle Short, fast-growing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

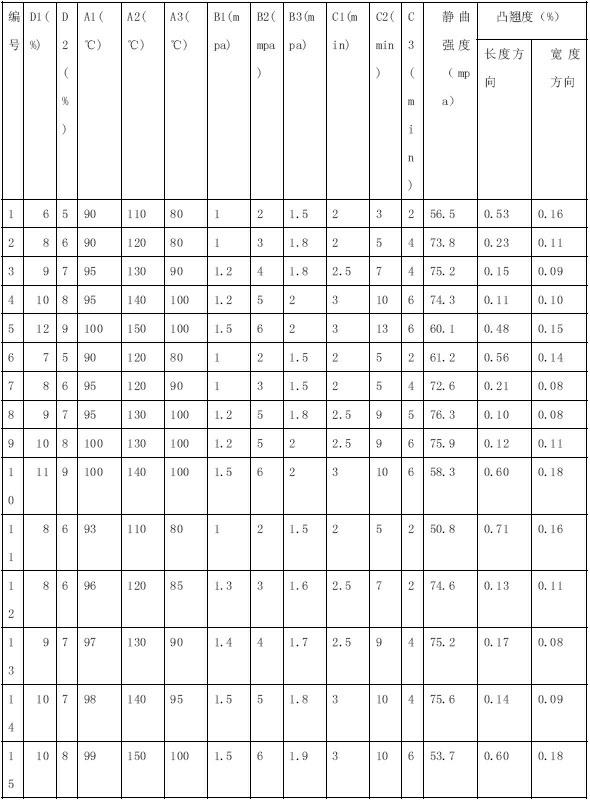

Examples

Embodiment 1

[0058] Embodiment 1: a kind of bamboo-wood composite panel production method, it comprises the following steps:

[0059] (1) Preparation of core board and surface board,

[0060] ① The preparation of the core board includes the following steps in turn:

[0061] a. The air-dry density is selected as 0.45g / cm 3 Poplar, the selected wood is crushed to obtain wood particles with a particle size of 2 to 5 mm;

[0062] b. Dry the prepared wood pellets. First, put the wood pellets on a natural drying site. When the air-dried to a moisture content of 35%, send them into a drying kiln for forced drying. Control the humidity in the drying kiln to 70% for 6 days , control the temperature on the first day at 50°C, and maintain a daily heating rate of 10°C until the temperature reaches 100°C, reducing the moisture content to 9%; in order to balance the moisture content among the wood particles, it is necessary to Carry out the moisture content balance step, that is, put the dried wood p...

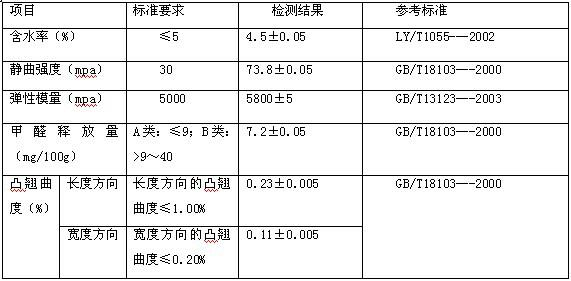

Embodiment 2

[0081] Embodiment 2: a kind of bamboo-wood composite board production method, it comprises the following steps:

[0082] (1) Preparation of core board and surface board,

[0083] ① The preparation of the core board includes the following steps in turn:

[0084] a. The air-dry density is selected as 0.55g / cm 3 For fir, the selected wood is pulverized to obtain wood particles with a particle size of 3 to 6 mm;

[0085] b. Dry the prepared wood pellets. First, put the wood pellets on a natural drying site. When the air-dried to a moisture content of 35%, send them into a drying kiln for forced drying. Control the humidity in the drying kiln to 80% for 5 days , control the temperature on the first day to 60°C, and maintain a daily heating rate of 10°C until the temperature reaches 100°C, reducing the moisture content to 10%; in order to balance the moisture content among the wood particles, it is necessary to Carry out the moisture content balance step, that is, put the dried w...

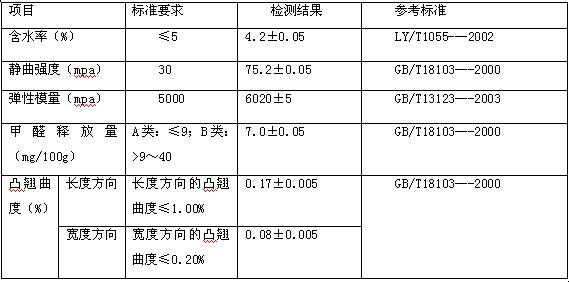

Embodiment 3

[0104] Embodiment 3: a kind of bamboo-wood composite board production method, it comprises the following steps:

[0105] (1) Preparation of core board and surface board,

[0106] ① The preparation of the core board includes the following steps in turn:

[0107] a. The selected air-dry density is 0.65g / cm 3 Pine wood, the selected wood is crushed to obtain wood particles with a particle size of 1 to 5mm;

[0108] b. Dry the obtained wood pellets. First, put the wood pellets on a natural drying site. When air-dried to a moisture content of 35%, send them into a drying kiln for forced drying. Control the humidity in the drying kiln to 90% for 5 days , control the temperature on the first day to 60°C, and maintain a daily heating rate of 10°C until the temperature reaches 100°C, reducing the moisture content to 11%; in order to balance the moisture content among the wood particles, it is necessary to Carry out the moisture content balance step, that is, put the dried wood parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com