Manufacturing method of fluorine plastic sleeve

A manufacturing method, the technology of fluoroplastics, applied in the field of polymer materials, can solve the problems of unsatisfactory temperature resistance, wear resistance, flexibility, comfort, and lifespan decline, etc., to ensure flexibility, comfort and long-term creep resistance Fatigue, overcoming creep and wear resistance, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

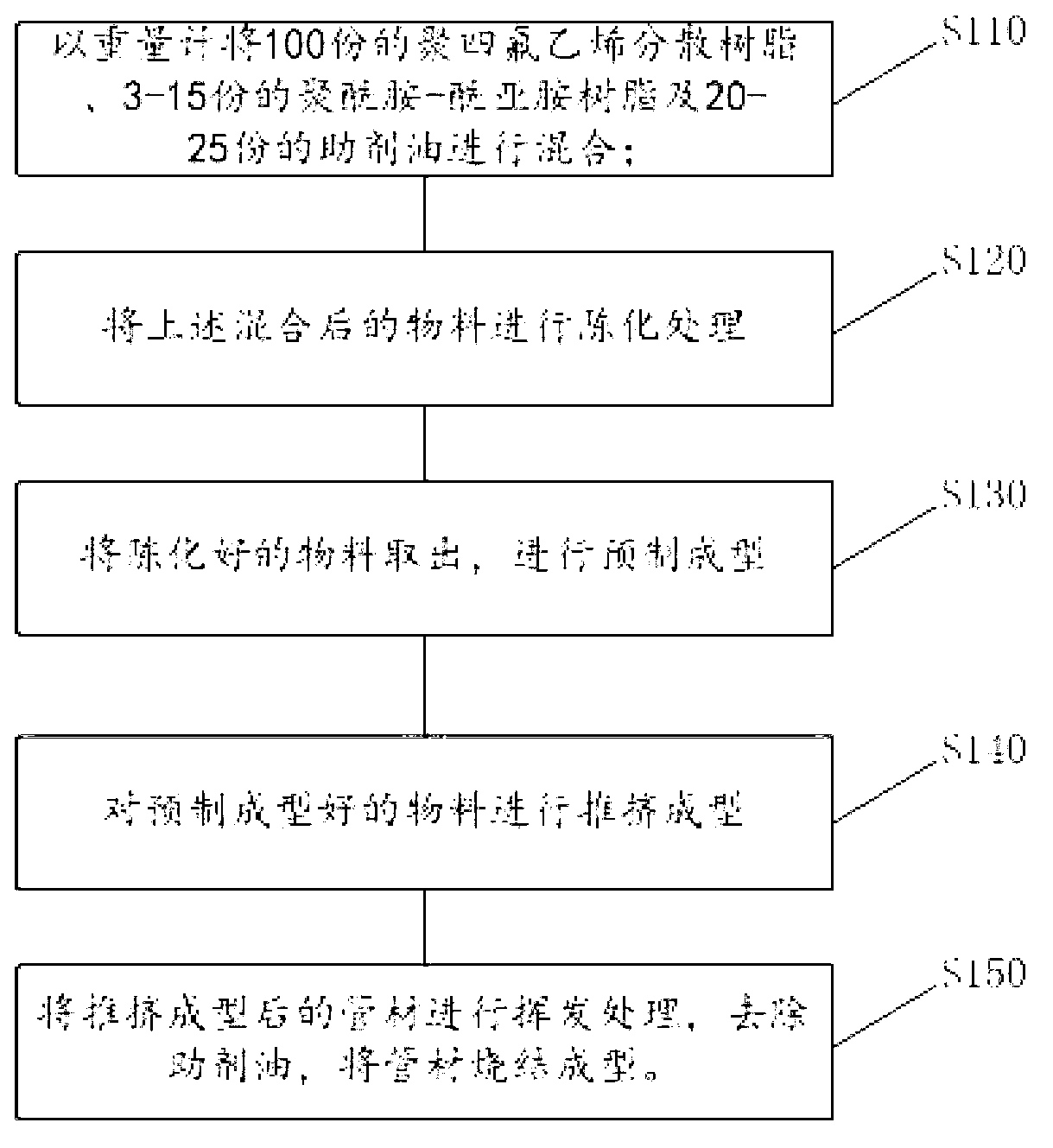

[0021] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The fluoroplastic provided by an embodiment of the present invention is prepared from the following materials in the attached parts by weight: 100 parts of polytetrafluoroethylene dispersion resin (PTFE dispersion resin); 3-15 parts of polyamide-imide resin (PAI resin) parts; auxiliary oil 20-25 parts.

[0023] In the embodiment of the present invention, the particle size of the ethylene dispersion resin is 400-650 μm, the apparent density is 400-500 g / l, and the extrusion force RR1600=30-50 MPa.

[0024] Preferably, the ethylene dispersion resin has a particle size of 400 μm, an apparent density of 500 g / l, and an extrusion force of RR1600=30MP.

[0025] In the embodiment of the present invention, the particle size of the polyamide-imi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com