Aluminum silicate/nickel-chromium stainless steel wire fireproof rolling curtain cloth and manufacturing method thereof

A technology of stainless steel wire and manufacturing method, which is applied in the field of aluminum silicate/nickel-chromium stainless steel wire fireproof rolling shutter fabric and manufacturing field, can solve the problems of failure of strength loss to meet fire protection requirements, cracking and collapse, melting deformation, etc., and can ensure the tightness of the fabric. And fire resistance, improve breaking strength, enhance the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method for making the aluminum silicate / nickel-chromium stainless steel wire fireproof rolling curtain fabric of the present invention will be further described below in conjunction with the accompanying drawings.

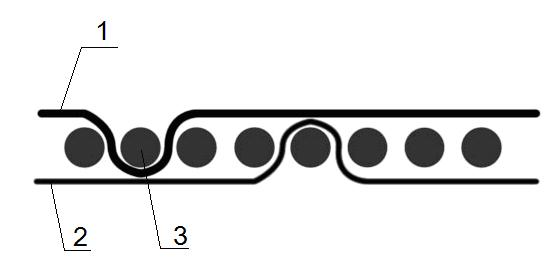

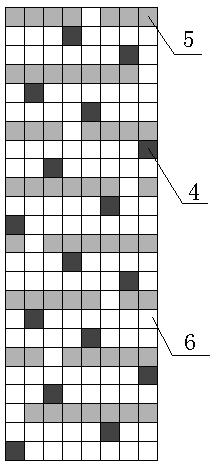

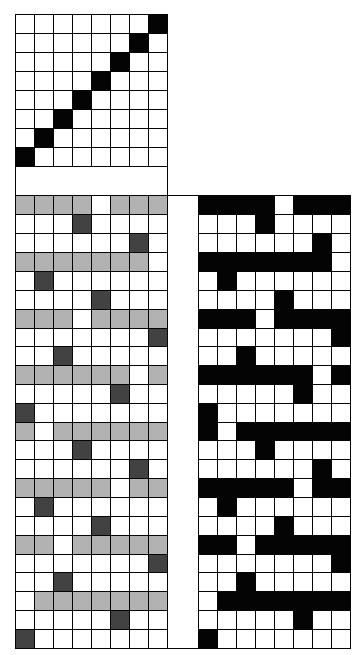

[0029] In the present embodiment, eight pieces of five flying weft satins are adopted as the table weave, and eight pieces of changing warp satins are used in the inner weave, and the surface weft and the inner weft are woven into the fabric in an arrangement ratio of 2, 1, and 1. Its latitudinal section structure is as figure 1 shown. The warp of the fabric is made of aluminum silicate / nickel-chromium stainless steel wire and twisted, the surface weft is made of aluminum silicate yarn, and the inner weft is made of nickel-chromium stainless steel wire. The fabric structure diagram is as follows: figure 2 As shown, the upper machine diagram is as follows image 3 shown.

[0030] The present embodiment adopts following technological process:

[0031]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com