Patents

Literature

156 results about "Lipophobicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lipophobicity, also sometimes called lipophobia (from the Greek λιποφοβία from λίπος lipos "fat" and φόβος phobos "fear"), is a chemical property of chemical compounds which means "fat rejection", literally "fear of fat". Lipophobic compounds are those not soluble in lipids or other non-polar solvents. From the other point of view, they do not absorb fats.

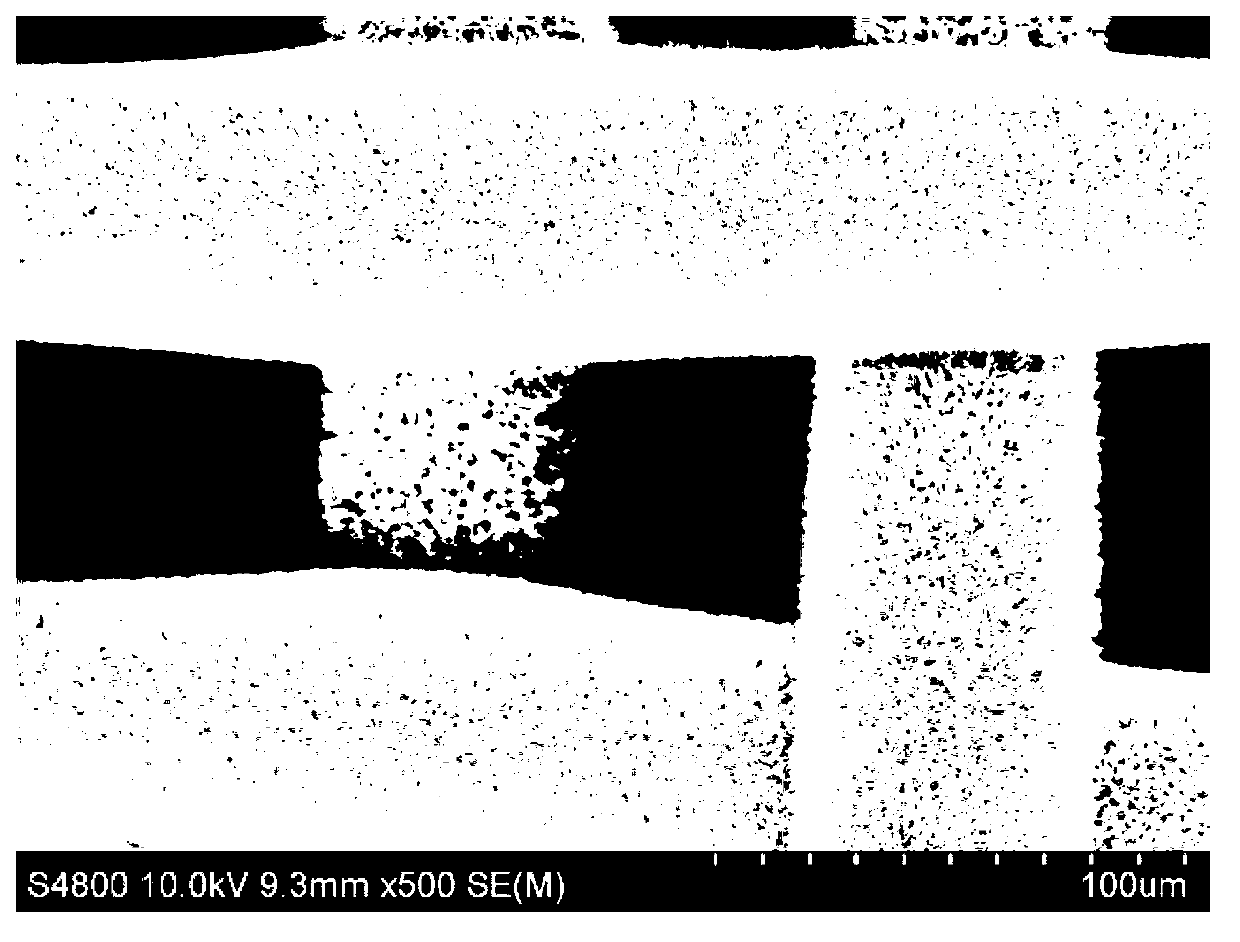

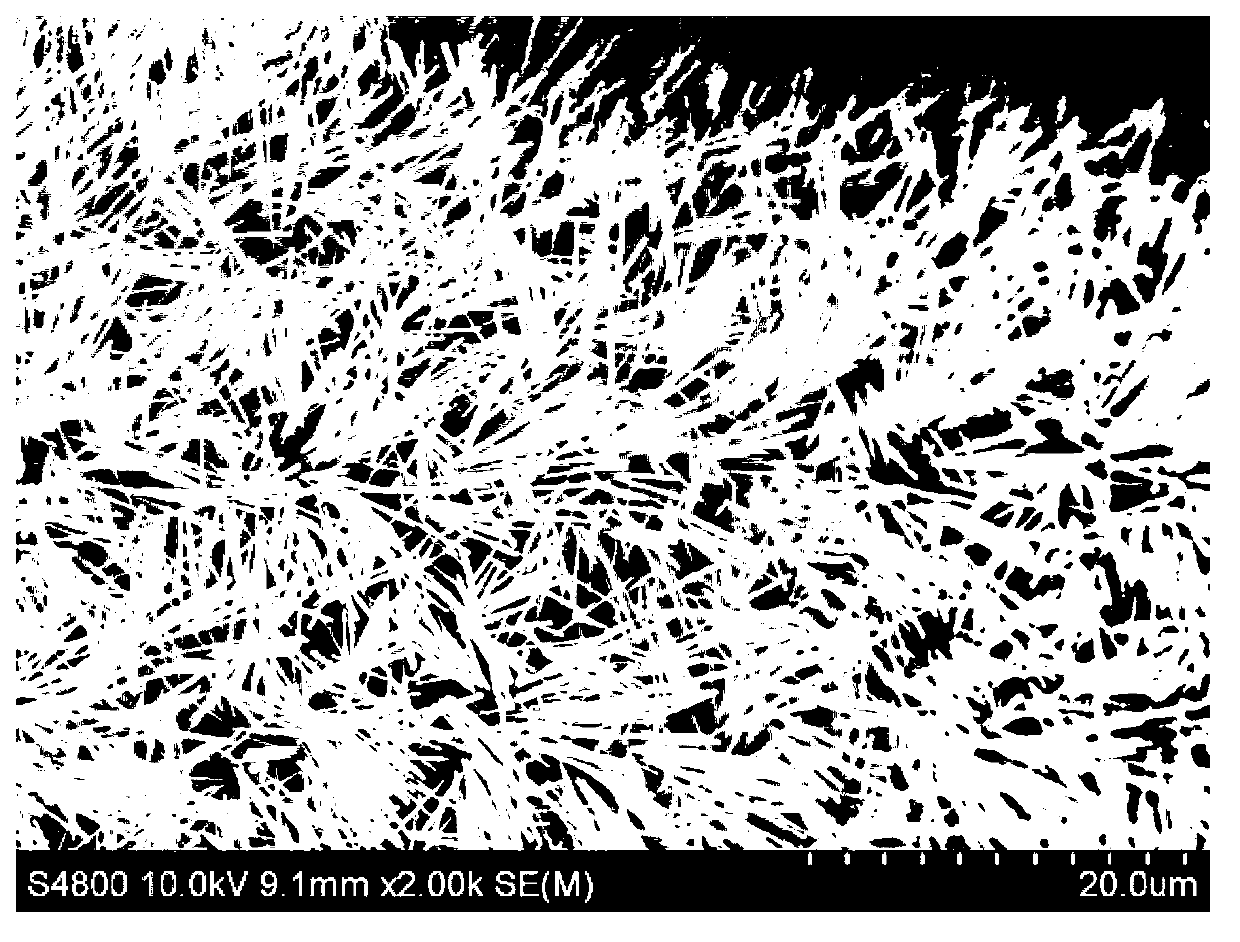

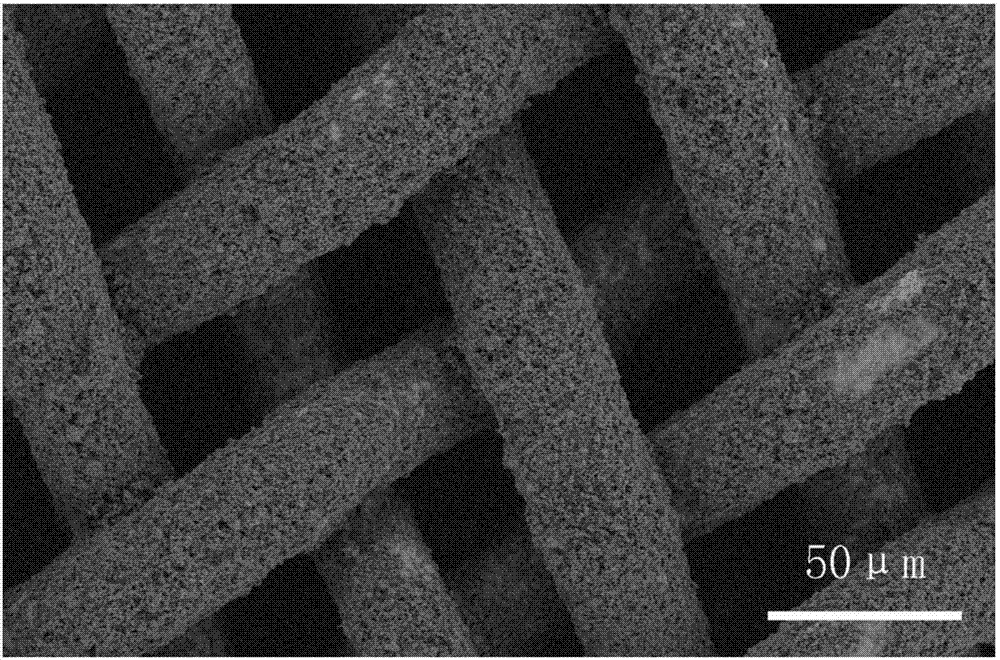

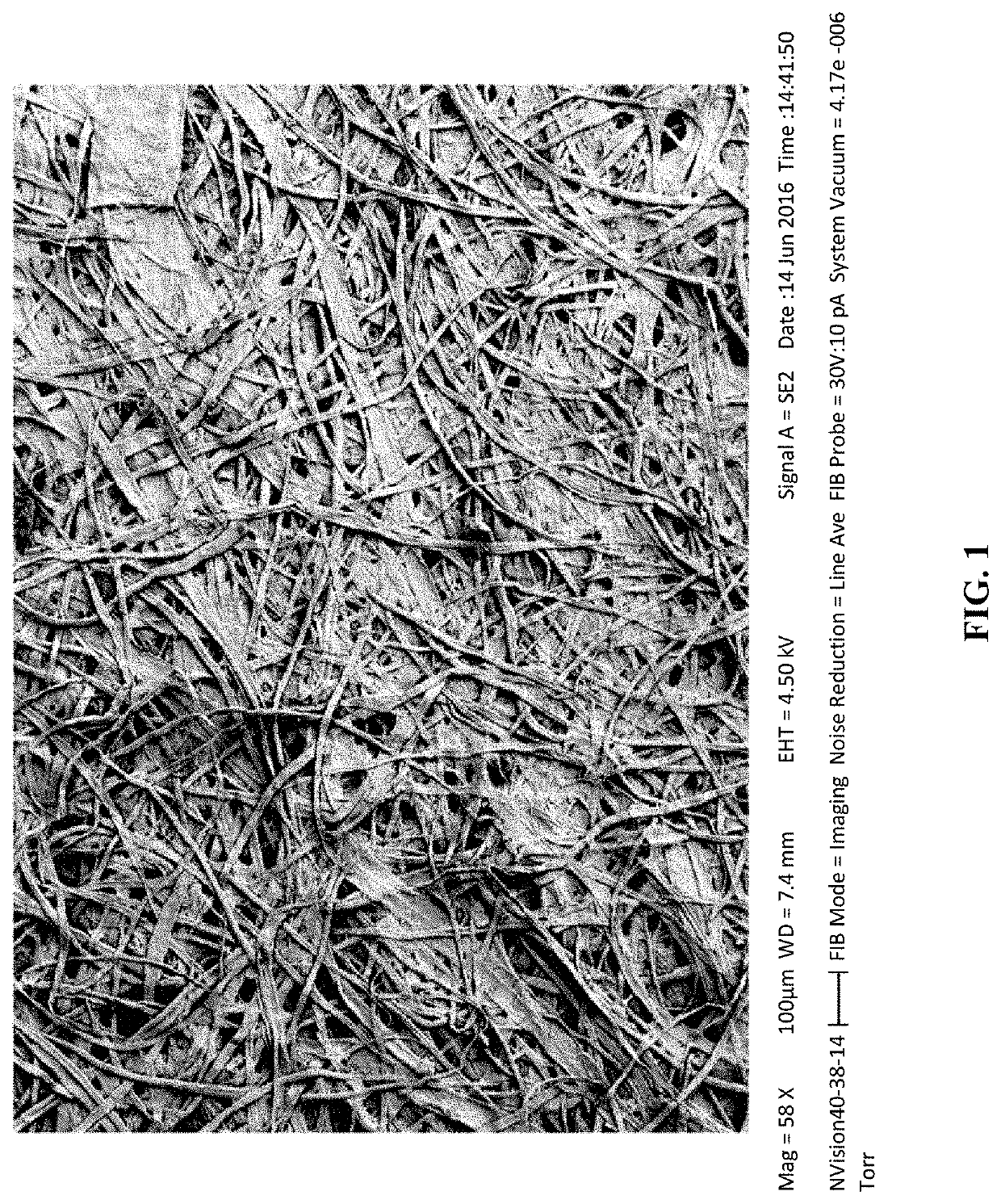

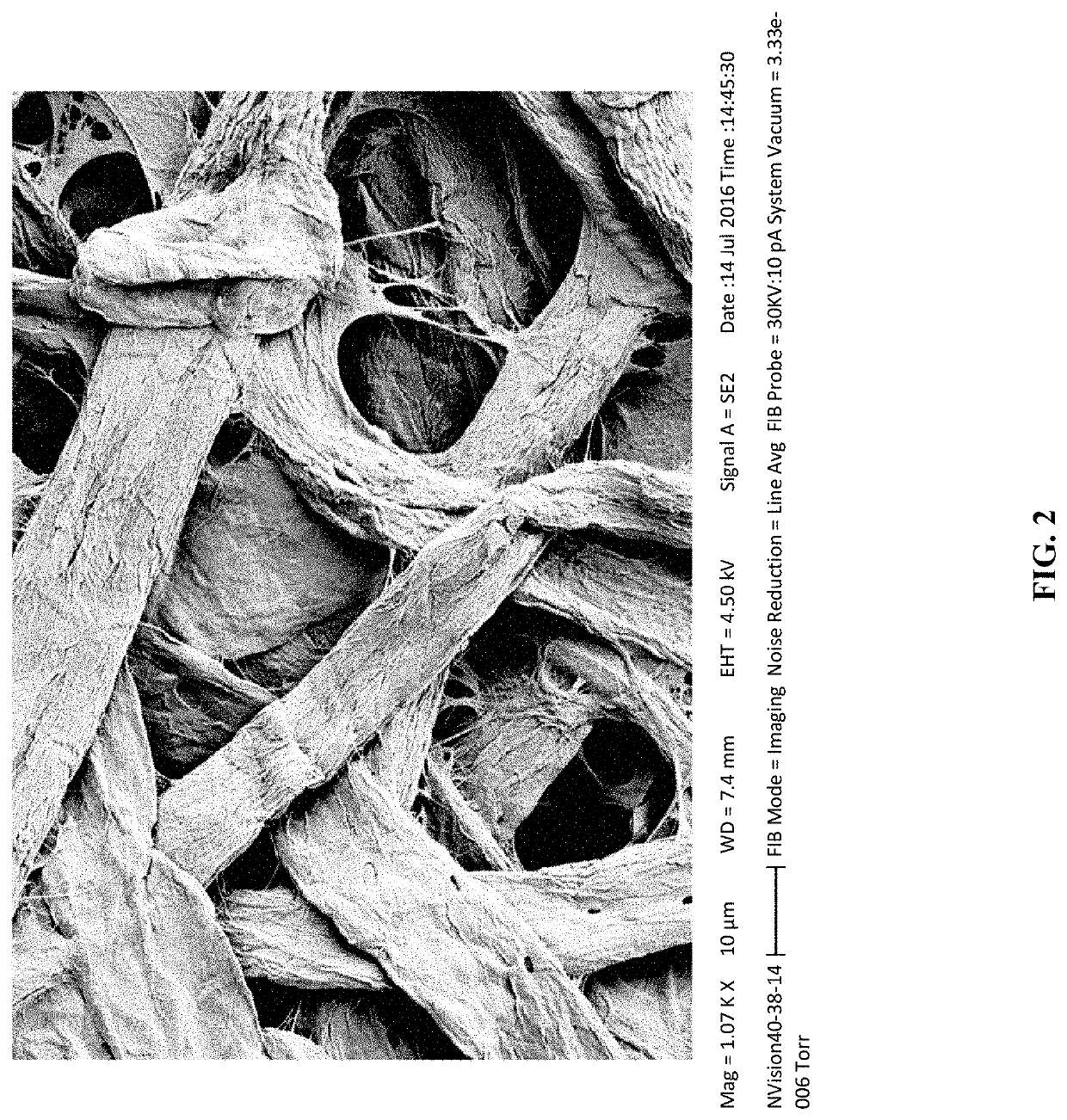

Separation net membrane with super-hydrophilicity/underwater super-lipophobicity as well as preparation method and application thereof

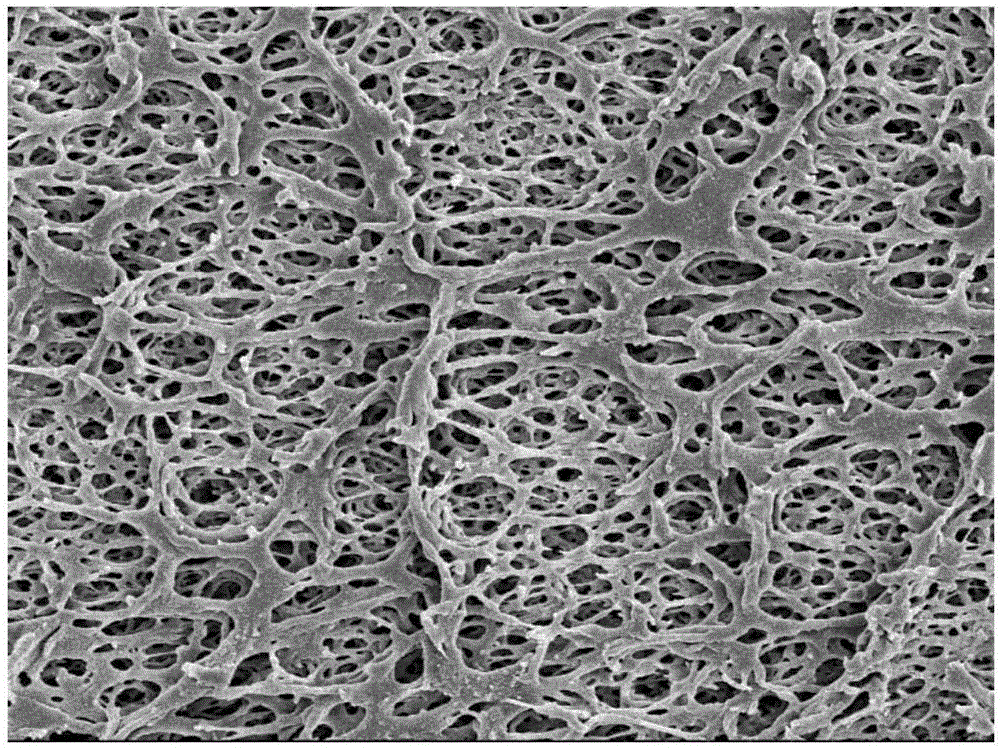

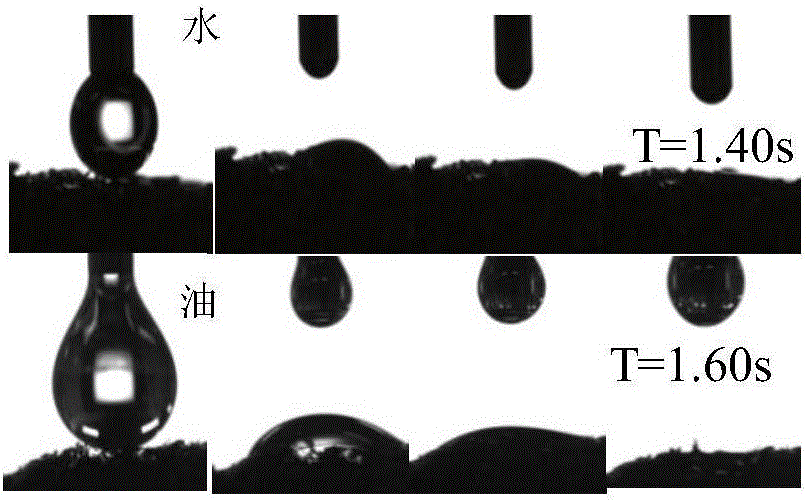

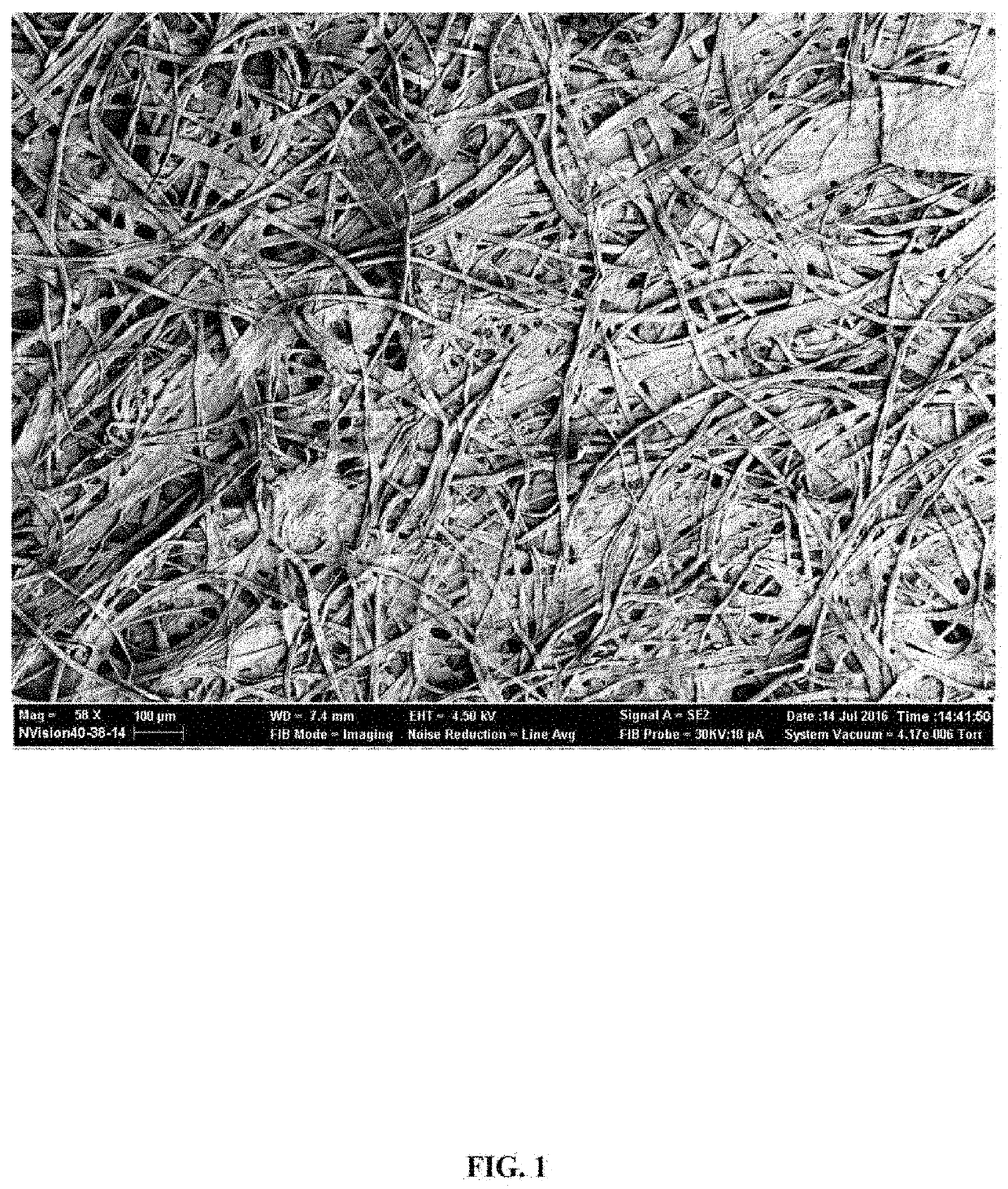

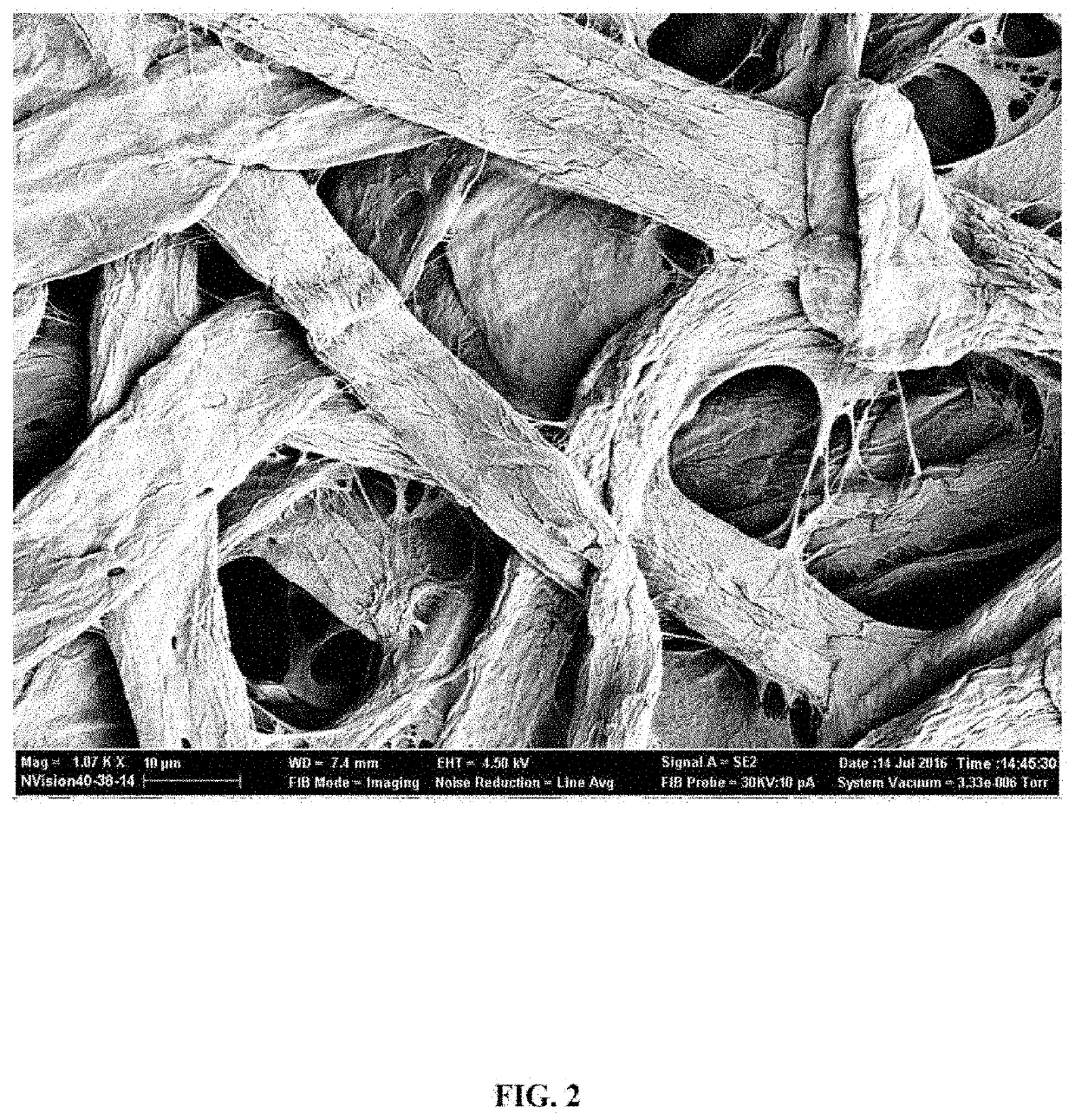

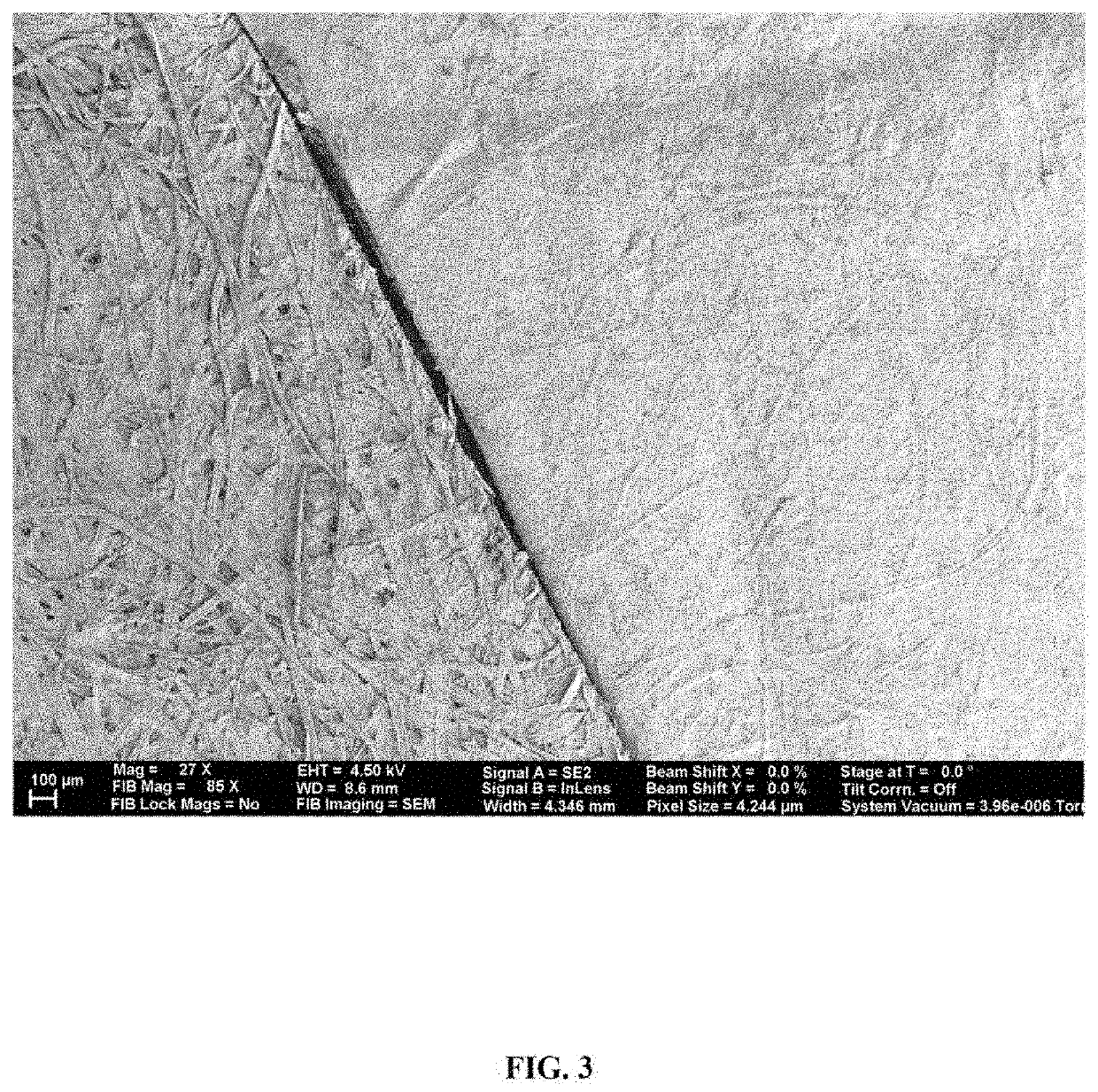

The invention discloses a separation net membrane with super-hydrophilicity / underwater super-lipophobicity as well as a preparation method and an application thereof. The separation net membrane comprises a supporting body with a grid structure and a nano wire growing on the grid structure, wherein the size of a grid is 100-2000 meshes; the length of the nano wire is 0.1-100 microns and the diameter is 10-1000nm; and the material of the nano wire comprises a metal hydroxide and / or a metal oxide. The preparation method comprises the following step of immersing the supporting body with the grid structure by an alkaline solution containing an oxidant until the nano wire grows on the grid structure to obtain a target product. The separation net membrane disclosed by the invention has the super-hydrophilicity and the underwater super-lipophobicity and can be used for carrying out oil-water separation treatment on various types of oil-water mixing systems; the separation net membrane has the advantages of high separation efficiency, high separation purity, fast separation speed, no need of external force driving, easiness in cleaning, good pollution resistance, energy conservation, environmental friendliness, long service life and the like; and meanwhile, the separation net membrane is simple in preparation process and low in cost, is environment-friendly, and is suitable for large-scale production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

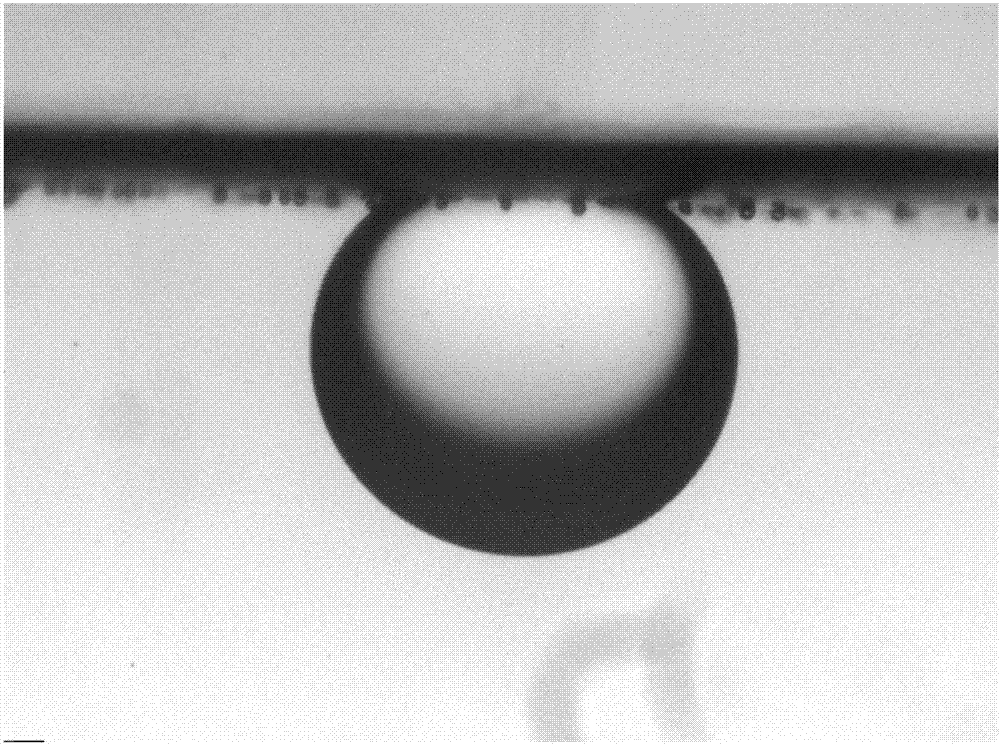

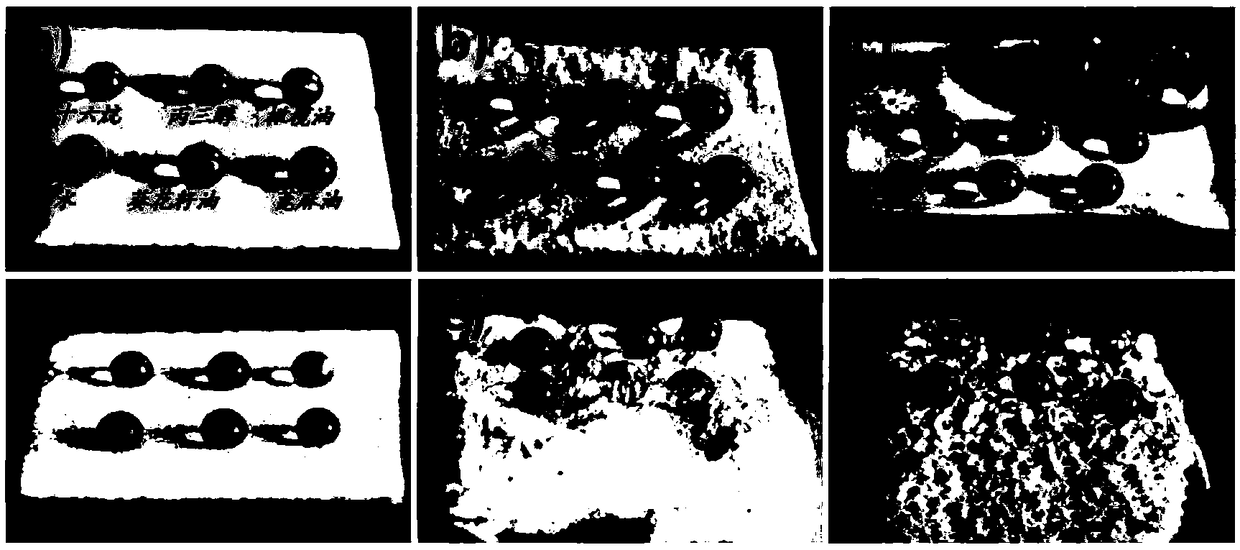

Responsive oil and water separation net film with underwater super lipophobicity property and preparation method thereof

ActiveCN103111096AIncrease speedReduce separation costsLiquid separationCross-linkUltraviolet lights

The invention discloses a responsive oil and water separation net film with an underwater super lipophobicity property and a preparation method thereof. The method comprises the following steps of: (1) dissolving a polymer monomer, a photoinitiator, a cross-linking agent and a thickening agent in water so as to obtain a mixed solution; (2) soaking a fabric net in the mixed solution; and (3) taking out the fabric net, carrying out a polymerization reaction on the soaked fabric net in ultraviolet light the wavelength of which is 365nm so as to obtain a polymer hydrogel coating layer in the fabric net, and then obtain the responsive oil and water separation net film with the underwater super lipophobicity property. The responsive oil and water separation net film with the underwater super lipophobicity property, provided by the invention, has the advantages that the oil-contaminated water can be separated, meanwhile, the temperature and pH dual responsive characteristics are realized, the controllable oil and water separation is realized, a separation device is simplified, and the separation cost is saved.

Owner:TSINGHUA UNIV

Superhydrophilic underwater-superlipophobic oil-water separation membrane, and preparation method thereof

InactiveCN107583470AGood film formingImprove hydrophilicitySemi-permeable membranesCross-linkPolyvinyl alcohol

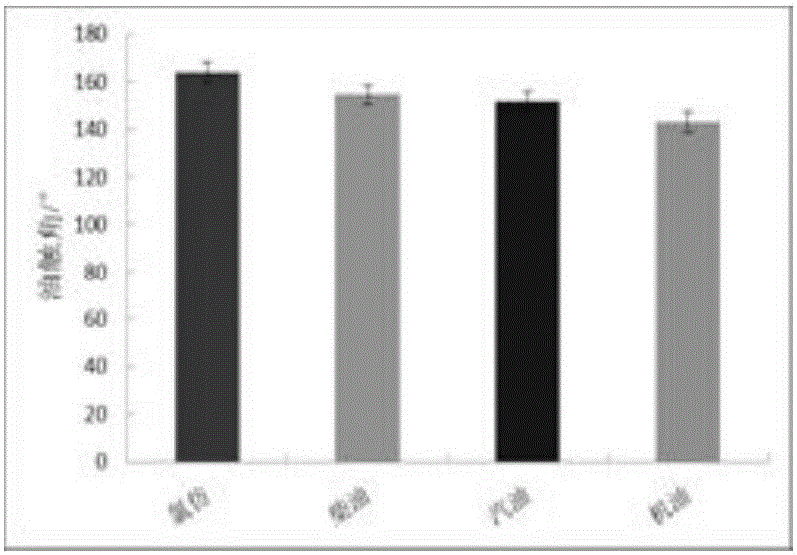

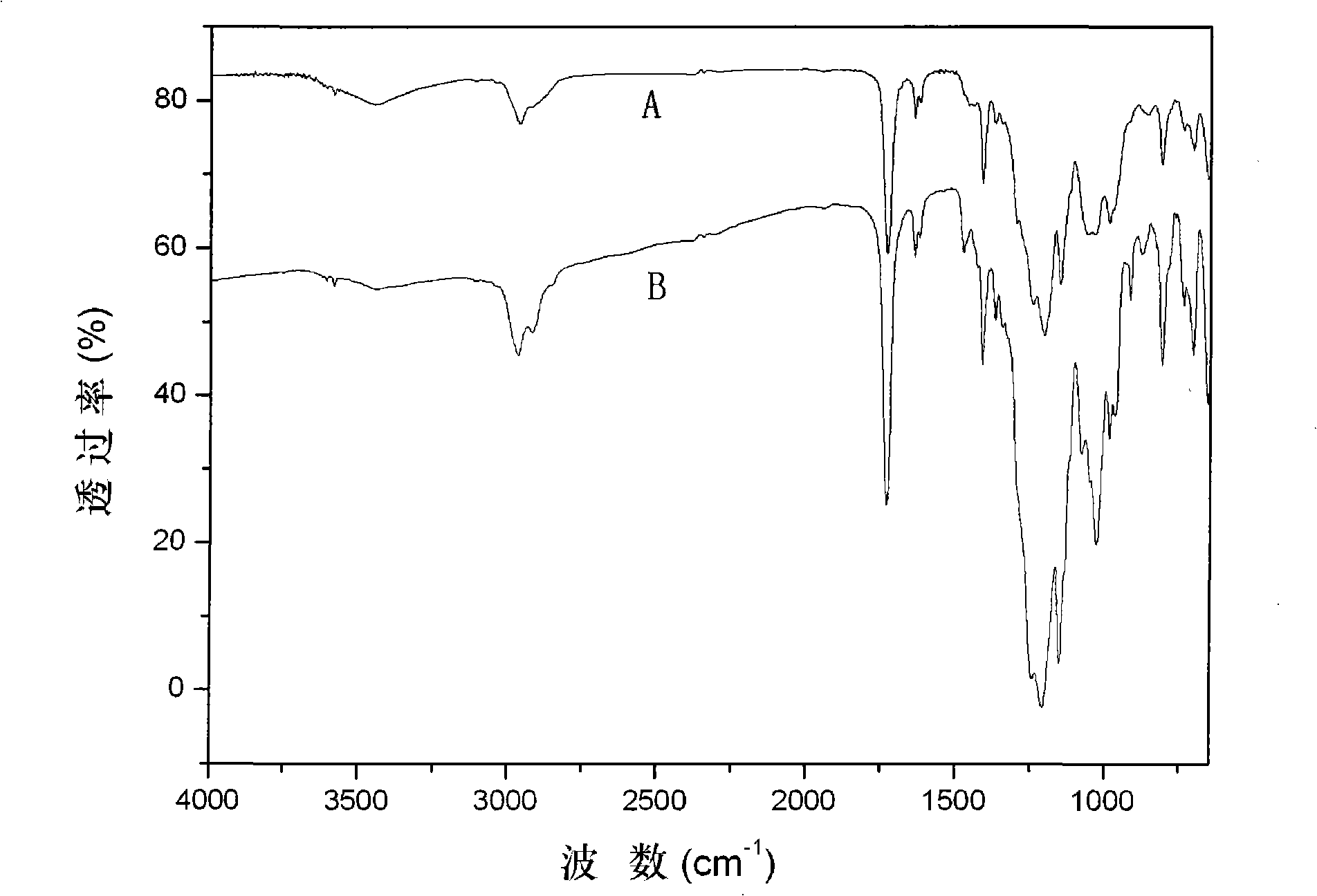

The invention discloses a superhydrophilic underwater-superlipophobic oil-water separation membrane, and a preparation method thereof. According to the preparation method, stainless steel wire mesh ornylon cloth are modified with a polyvinyl alcohol-silicon dioxide composite coating so as to change the surface properties and provide the stainless steel wire mesh or nylon cloth with super hydrophilicity and underwater super lipophobicity; dip coating process is adopted so as to realize loading of the surface of the stainless steel wire mesh or nylon cloth with polyvinyl alcohol-silicon dioxide, wherein a polyvinyl alcohol aqueous solution and an ethanol dispersion solution of silicon dioxide are prepared firstly, and are mixed via ultrasonic treatment, the pH value is adjusted, and a cross-linking agent is added so as to obtain a coating solution, and dip coating is adopted so as to obtain the superhydrophilic / underwater-superlipophobic oil-water separation membrane. The superhydrophilic underwater-superlipophobic oil-water separation membrane possesses both super hydrophilicity and underwater super lipophobicity, is suitable for treatment of sewage containing n-hexane, cyclohexane, diesel oil, soya-bean oil, lubricating oil, and silicone oil, and possesses excellent oil water separation performance.

Owner:SHANGHAI UNIV

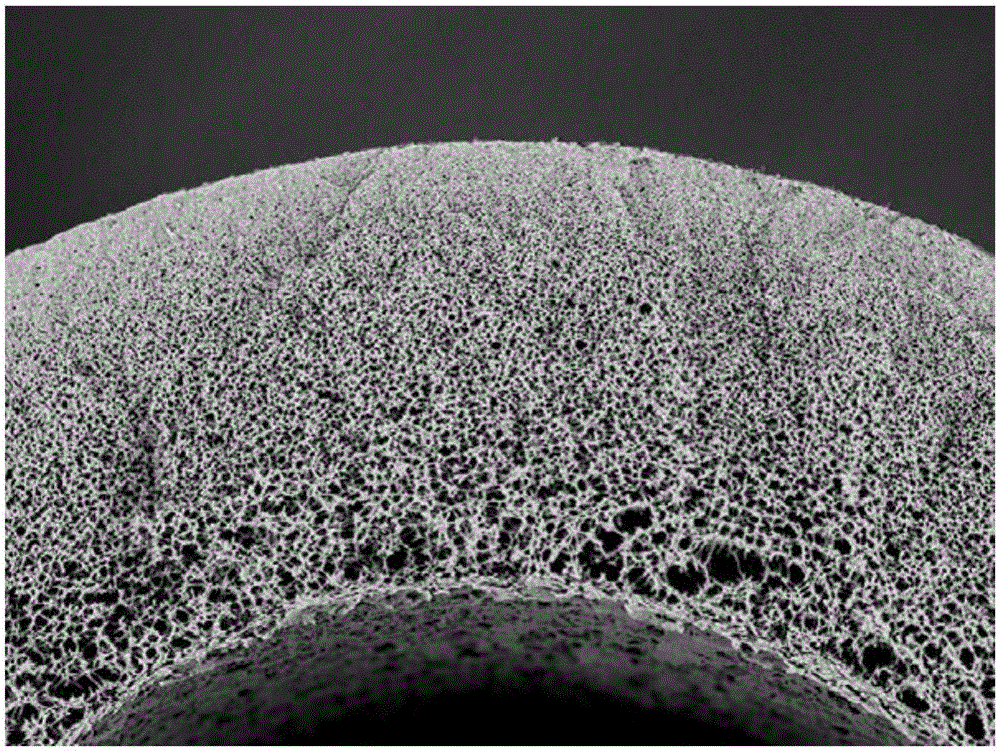

Organic/inorganic hybrid hydrophilic modified hollow fiber polymer film and preparation method thereof

The invention discloses an organic / inorganic hybrid hydrophilic modified hollow fiber polymer film and a preparation method thereof. According to the preparation method, a cross-linked network in which organic macromolecular chains and inorganic SiO2 nano particles are mutually crossed is generated on a porous surface of a film through the utilization of hydrolysis of a silane coupling agent and silicate ester, an organic / inorganic hybrid modified silicon layer with a micro-nano composite structure is formed on the micro-porous surface of the polymer hollow fiber film, and finally, the novel polymer hollow fiber film with super hydrophilic-underwater super lipophobicity is obtained. According to the invention, the content ratio of the silane coupling agent to the silicate ester is adjusted, so that the interface cross-linking degree of the cross-linked network of the film surface can be controlled, and further, the controllable adjustment of nano-scale micropores in the film surface can be realized. The organic / inorganic hybrid hydrophilic modified hollow fiber polymer film has long-lasting hydrophilicity, hydrophilic stability, ultrahigh water flux and ultrahigh anti-pollution performance, and can be widely applied to the fields of drinking water deep purification, industrial sewage treatment, condensation separation and oil-water separation of edible drinks, and the like.

Owner:江苏巨之澜科技有限公司

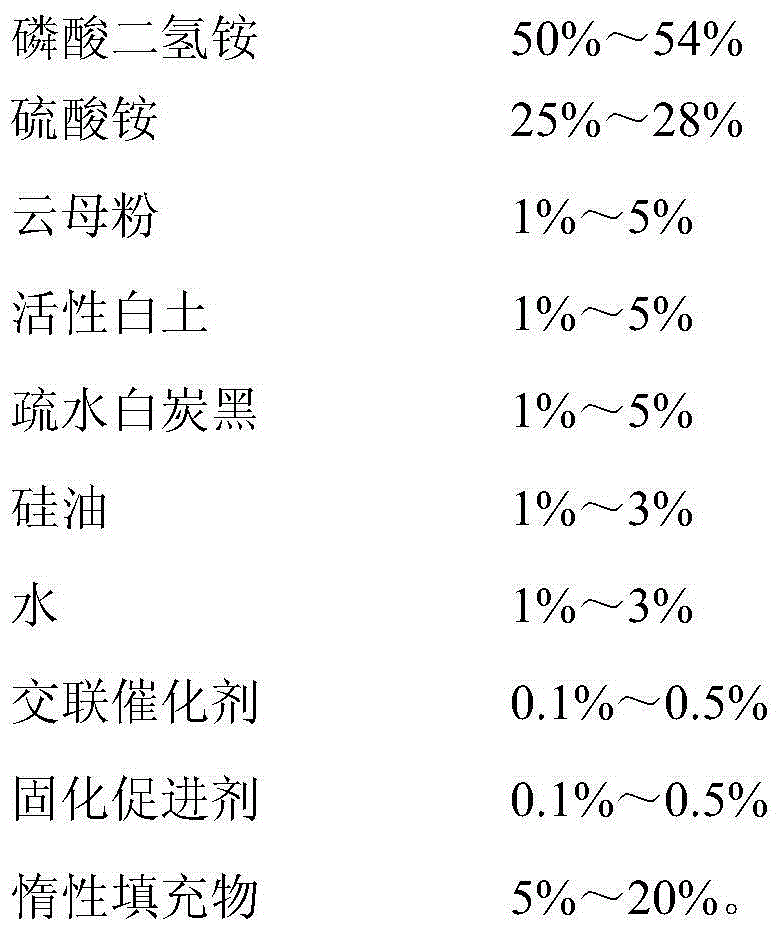

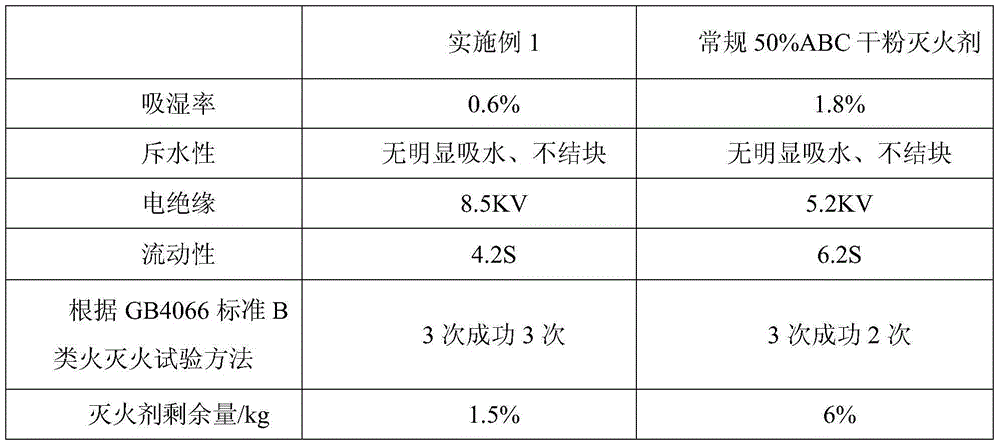

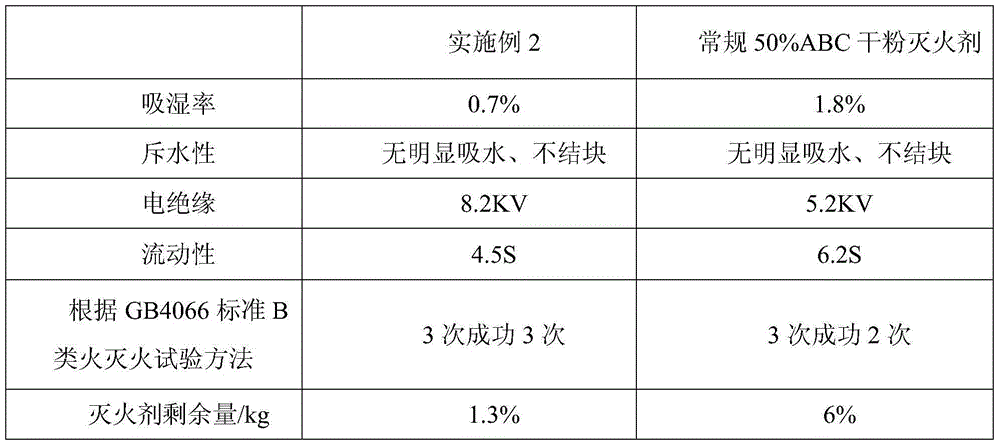

ABC dry powder extinguishing agent

ActiveCN104645541AImprove insulation performanceImprove hydrophobicityFire extinguisherHeat resistanceMoisture absorption

The invention discloses an ABC dry powder extinguishing agent. The dry powder extinguishing agent is characterized by comprising the following components by weight percent: 50%-54% of ammonium dihydrogen phosphate, 25%-28% of ammonium sulfate, 1%-5% of mica powder, 1%-5% of activated clay, 1%-5% of hydrophobic white carbon black, 1%-3% of silicone oil, 1%-3% of water, 0.1%-0.5% of a crosslinking catalyst, 0.1%-0.5% of a curing accelerator, and 5%-20% of inert filler. The ABC dry powder extinguishing agent is capable of effectively reducing moisture absorption, and has higher heat resistance, electric insulativity, hydrophobicity and lipophobicity, the expiration date is effectively prolonged, and the extinguishing performance of the product is guaranteed.

Owner:NINGBO NENGLIN FIRE FIGHTING EQUIP

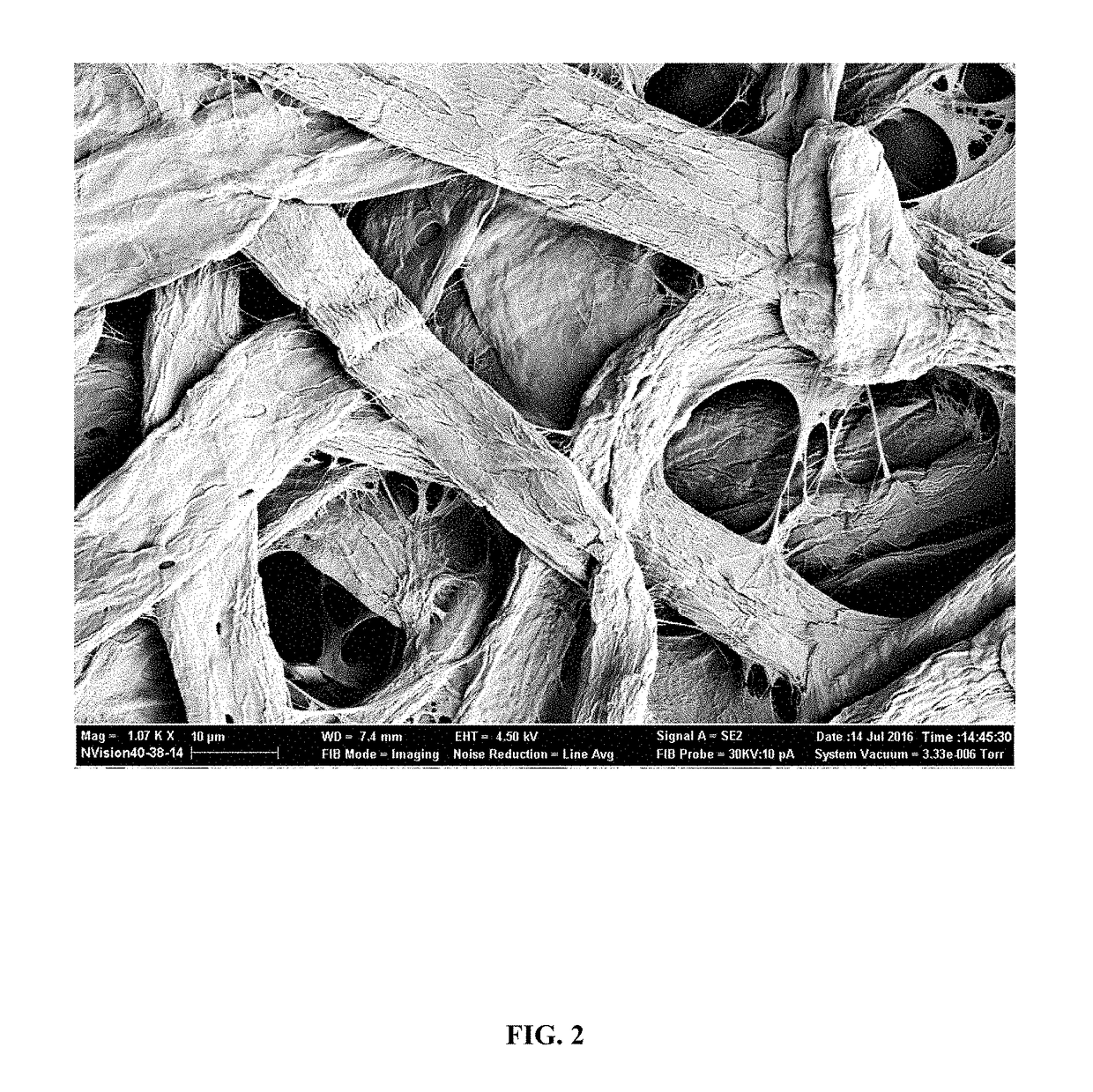

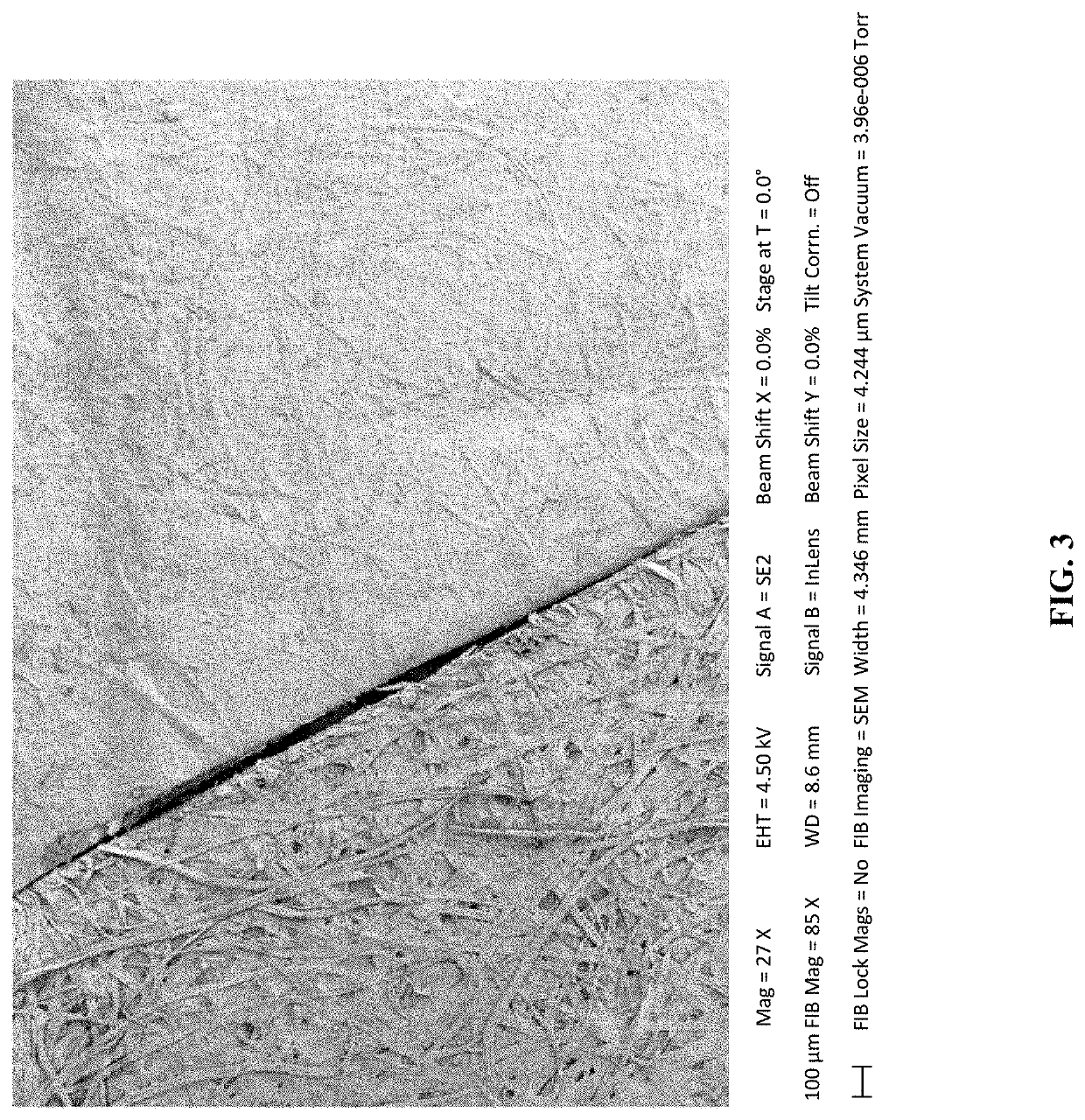

Methods for biobased derivatization of cellulosic surfaces

ActiveUS20180066073A1Generate/increase wet strengthHigh strengthFlexible coversWrappersCelluloseDerivatization

The present invention describes tunable methods of treating cellulosic materials with a composition that provides increased hydrophobicity and / or lipophobicity to such materials without sacrificing the biodegradability thereof. The methods as disclosed provide for binding of saccharide fatty acid esters on cellulosic materials, including that the disclosure provides products made by such methods. The materials thus treated display higher hydrophobicity, lipophobicity, barrier function, and mechanical properties, and may be used in any application where such features are desired.

Owner:HS MFG GRP LLC

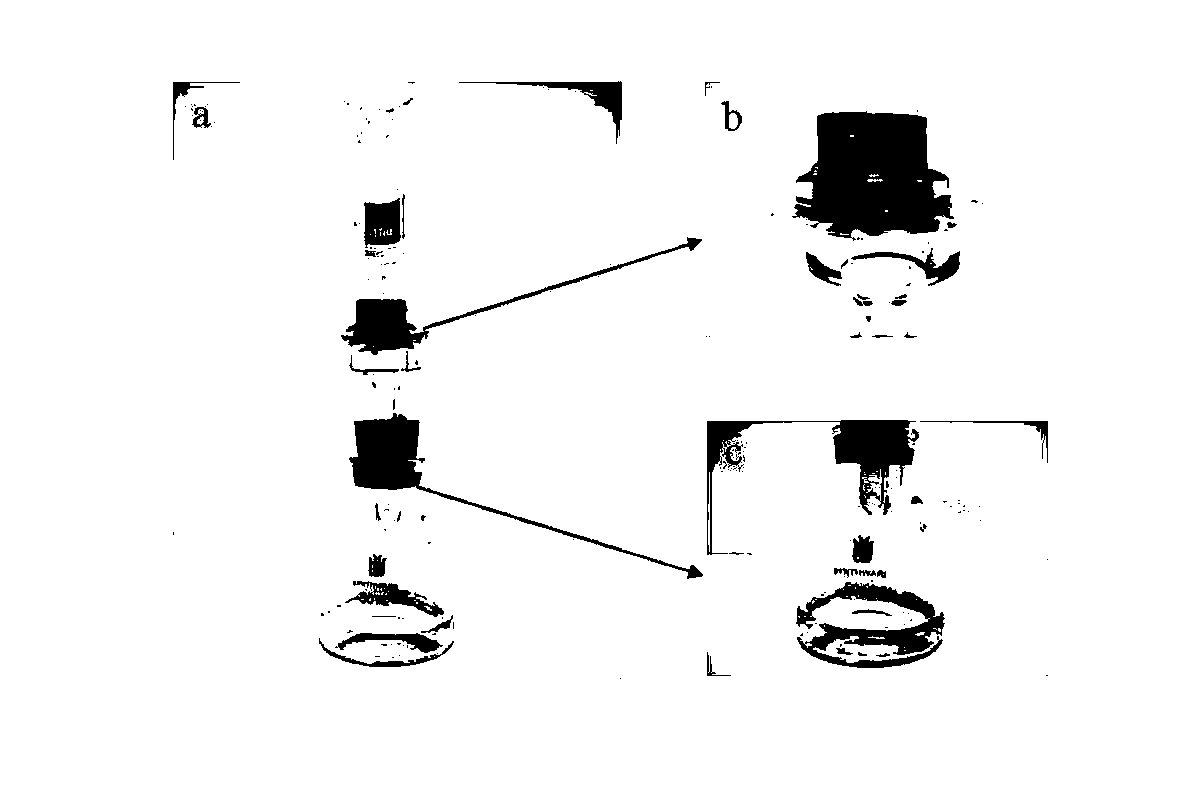

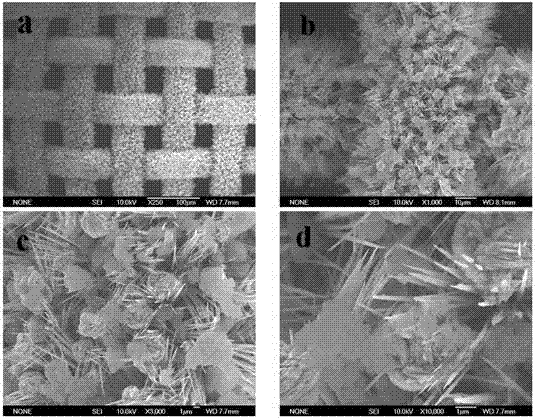

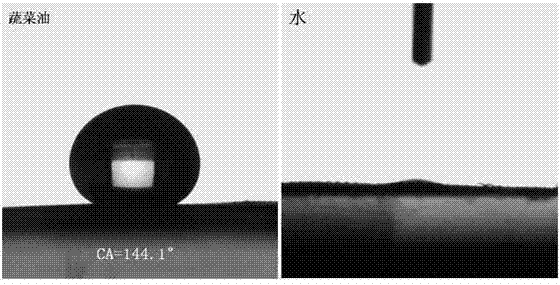

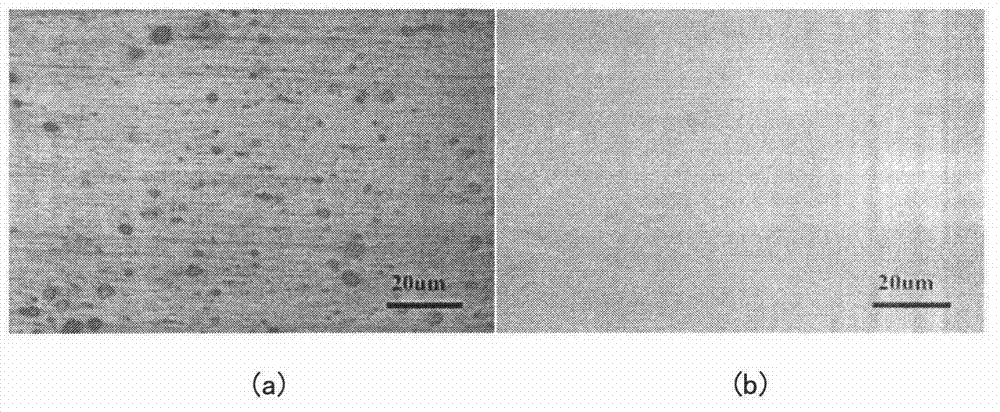

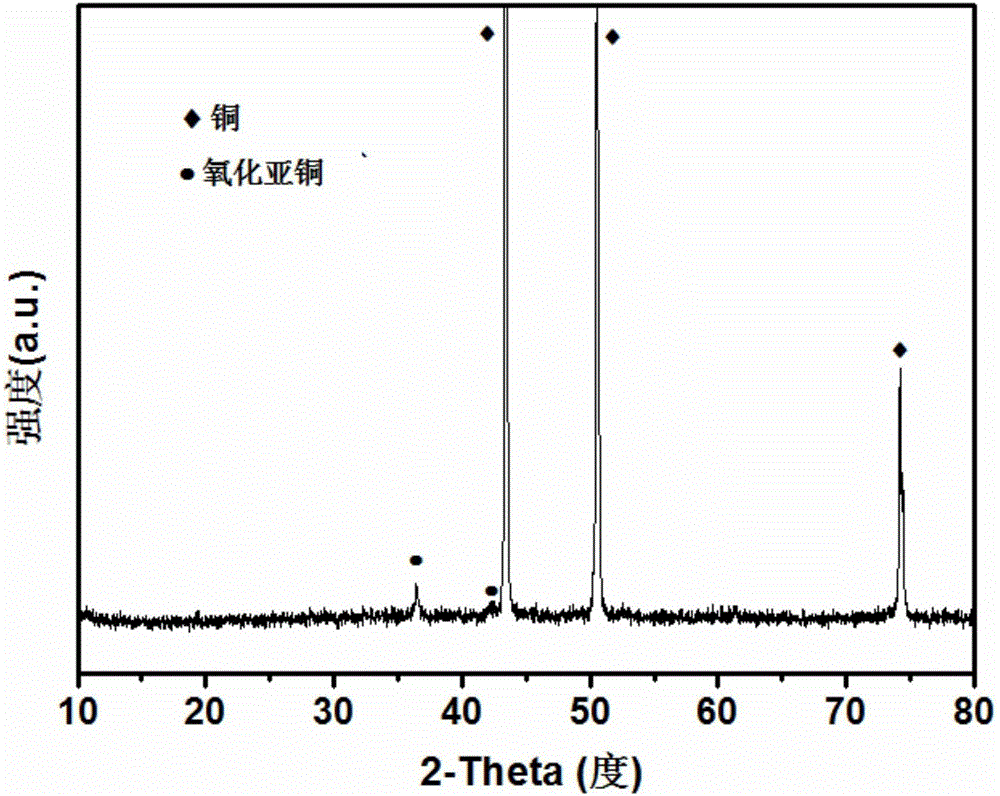

Preparation method of oil-water separation net membrane with super-hydrophilic lipophobicity

InactiveCN103566626AEasy to prepareShort timeLiquid separationVegetable oilSodium perfluorooctanoate

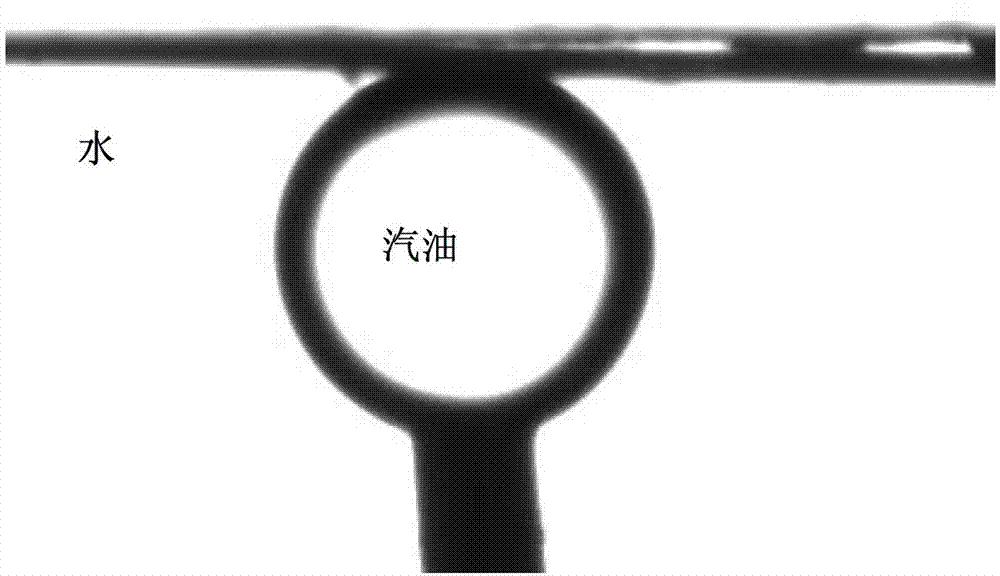

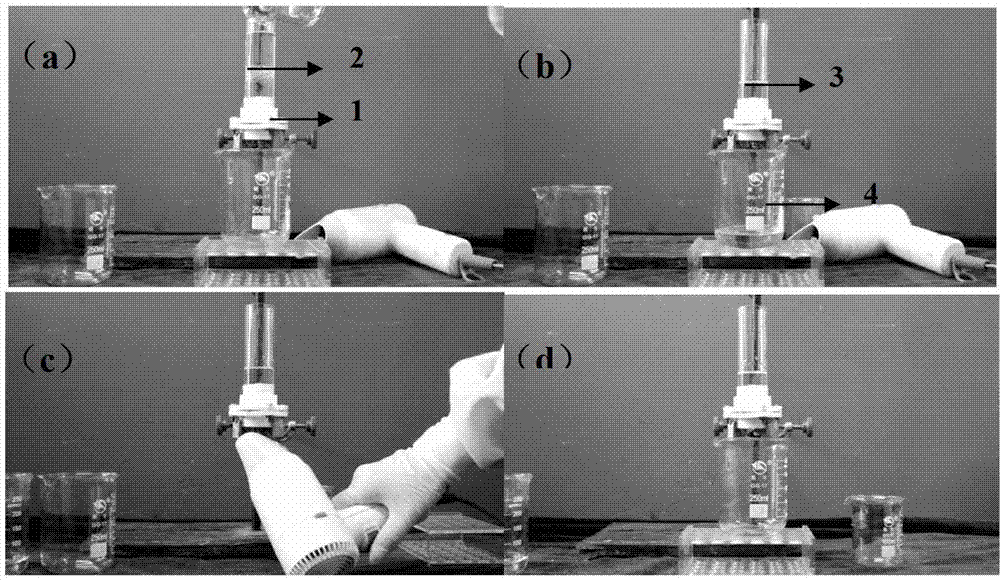

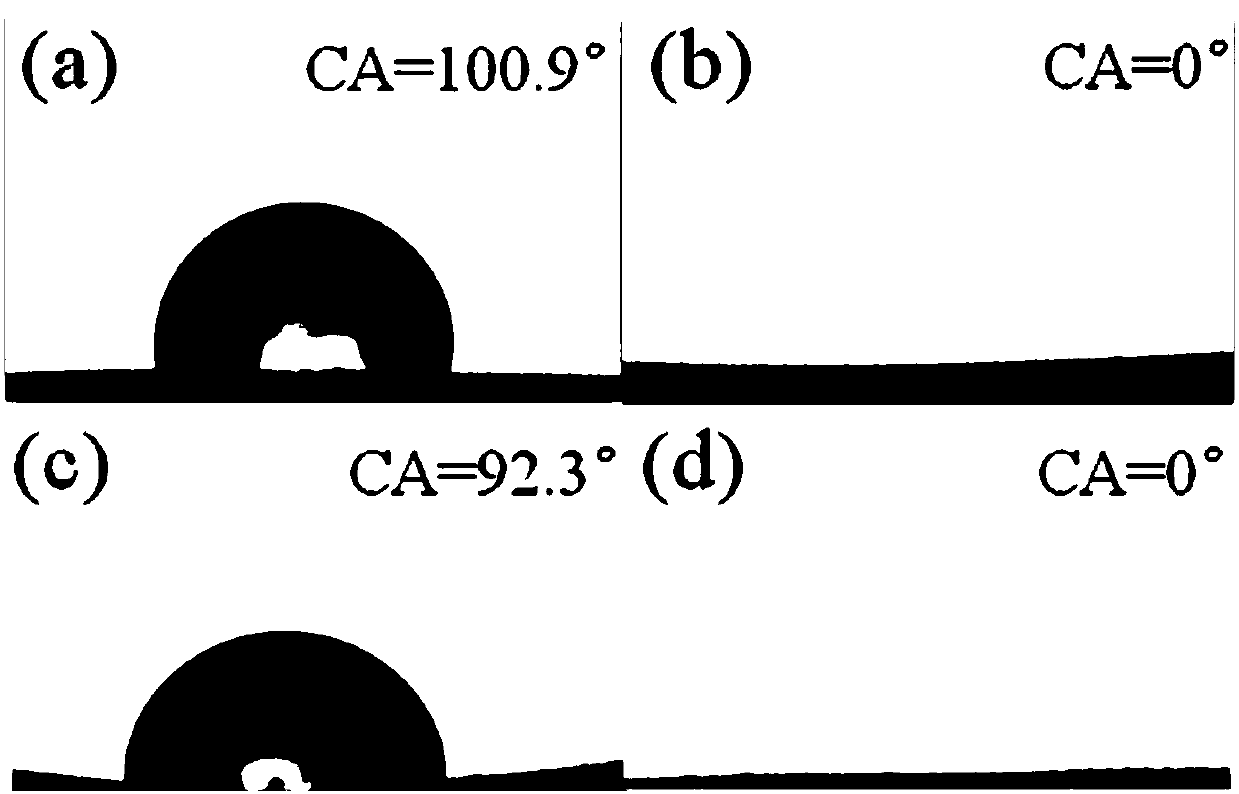

The invention discloses a preparation method of an oil-water separation net membrane with super-hydrophilic lipophobicity. The method comprises the steps that a red copper net serves as a substrate; a micro-nano needle structure is constructed by a simple solution soaking method; surface modification is performed by a poly dimethyl diallyl ammonium chloride-sodium perfluorooctanoate / silica compound. The prepared oil-water separation net membrane with the super-hydrophilic lipophobicity is used for oil-water separation. The method has the advantages that the preparation method of the oil-water separation net membrane with the super-hydrophilic lipophobicity is simple, short in time consuming and stable in performance, and requires no large instrument; the prepared oil-water separation net membrane is easy to clean and good in recycling; water permeation instead of oil permeation can be achieved when the net membrane provided by the method is applied to the oil-water separation; the net membrane can effectively perform the oil-water separation on vegetable oil and gasoline, and has a wide application prospect in the oil-water separation.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

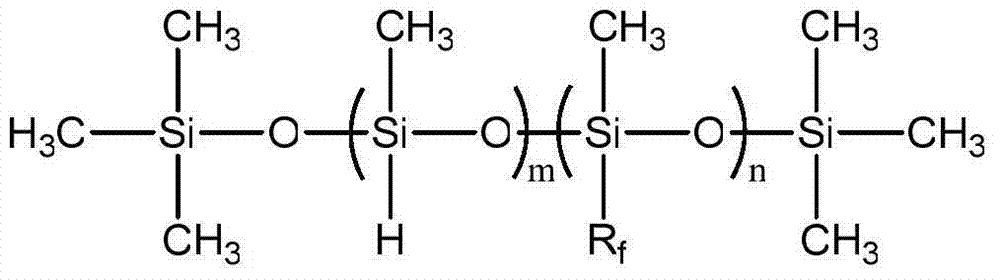

Preparation method and hydrophobic anti-icing application of POSS (polyhedral oligomeric silsesquioxane) crosslinking modified fluorine-silicon coating

The invention provides a preparation method and hydrophobic anti-icing application of a polyhedral oligomeric silsesquioxane (POSS)-containing crosslinking modified fluorine-silicon coating. The coating mainly involves a matrix component A fluoroalkyl polysiloxane, a matrix component B vinyl polysiloxane and a crosslinking reinforcer functional POSS, wherein the fluoroalkyl side chain can obviously change the hydrophobicity and lipophobicity of the coating, and the siloxane chain segment and the POSS are beneficial to reduce the water contact angle hysteresis of the coating. At low temperature, the fluoroalkyl chain exhibits rigidity, while the siloxane chain segment exhibits flexibility, so that the formed POSS crosslinking modified fluorine-silicon coating reduces adhesion to ice under the synergetic effect of fluorine and silicon, and the ice is easy to fall from the surface of the coating under the action of a small external force. According to the invention, the POSS crosslinking modified fluorine-silicon coating has low surface energy, water contact angle hysteresis and ice shear strength, and can be used in the field of hydrophobic and anti-icing coatings.

Owner:天津渤化讯创科技有限公司

Ceramic filter film of rare-earth modified attapulgite with nano coating and preparation method thereof

InactiveCN102614782AUniform pore size distributionLight in massSemi-permeable membranesCeramicwareRare earthPore diameter

Owner:SHANGHAI MARITIME UNIVERSITY

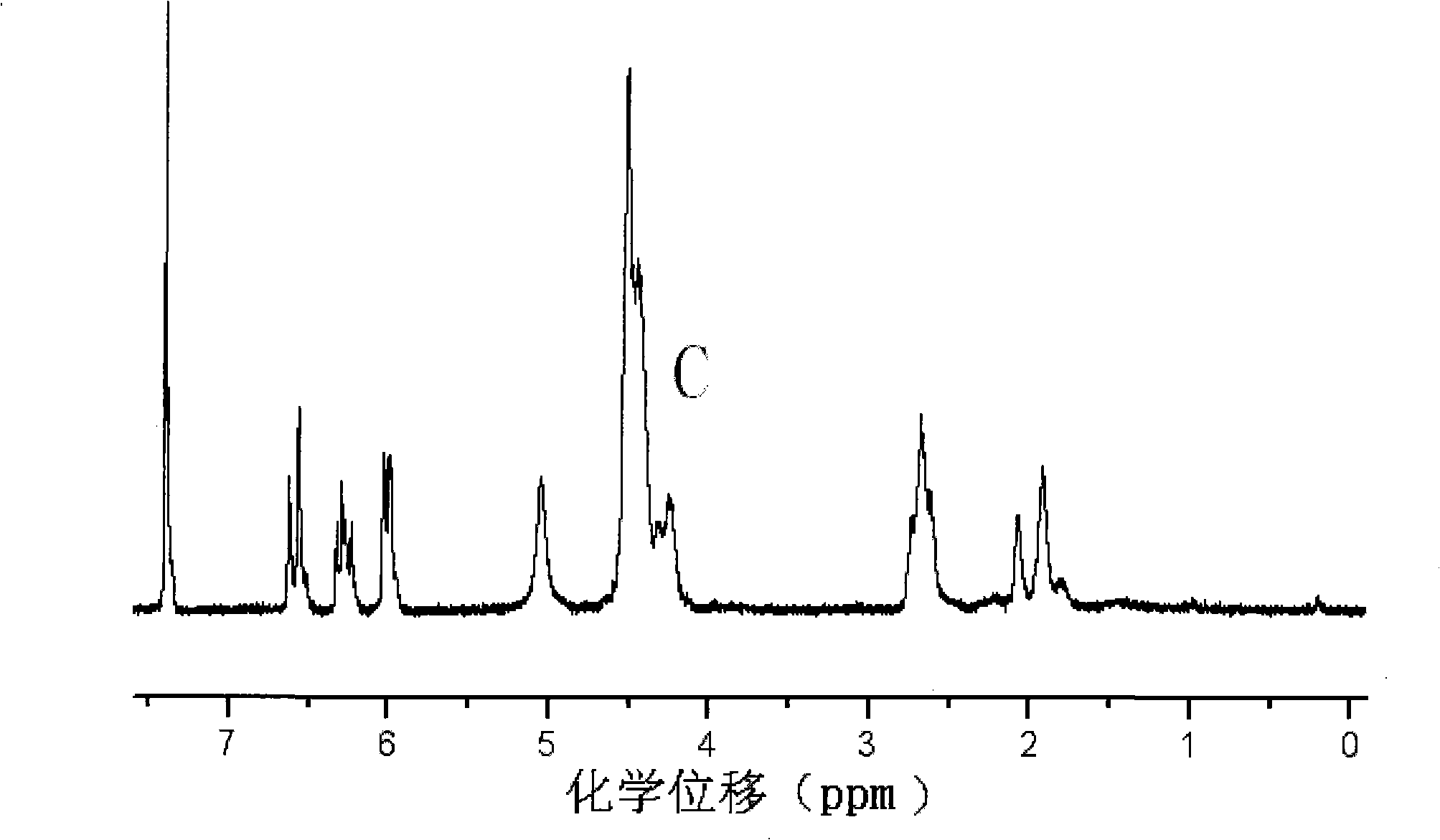

Preparation method for core-shell fluorinated polyurethane-acrylate latex

InactiveCN102924664AImprove grafting efficiencyFast polymerization rateCoatingsPolymer scienceFunctional monomer

The invention relates to a preparation method for core-shell fluorinated polyurethane-acrylate latex. The method comprises the following steps: placing polyether glycol and toluene diisocynate into a stirrer to prepare polyurethane; and emulsifying an emulsifier, butyl acrylate, methyl methacrylate, a functional monomer and a proper amount of water at high speed to prepare the core-shell fluorinated polyurethane-acrylate latex. By the method, the defects that the fluorinated acrylate in the prior art is independent of oil and water phases due to hydrophobicity and lipophobicity, effective micelle is difficult to form by the general surfactant and the grafting ratio is low are overcome. The core-shell fluorinated polyurethane-acrylate latex has a core-shell structure and the fluorinated acrylate is enriched in the shell, so a latex film has a large water contact angle. The using amount of the fluorinated acrylate monomer (G04) is 1 to 2 percent of the weight of the monomer and the using amount of polyurethane (PU) is 10 percent of the weight of a composite latex solid, so the preparation cost is low. The emulsifier does not need a fluorine-containing surfactant, so the polymerization rate is high, the grafting efficiency of the fluorinated acrylate monomer is high and the latex is stored stably.

Owner:江苏日出化工有限公司 +1

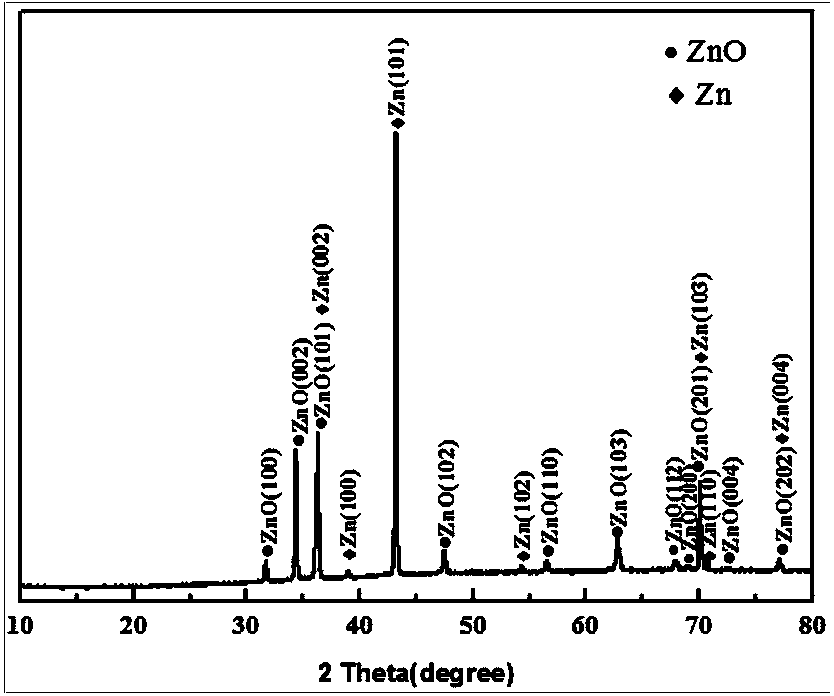

Preparation method of oil-water separation mesh film with super-hydrophilicity and super-lipophobicity

InactiveCN107080975AAchieve the purpose of separationIncrease water fluxFatty/oily/floating substances removal devicesLiquid separationAdhesiveOil water

The invention discloses a preparation method of an oil-water separation mesh film with super-hydrophilicity and super-lipophobicity. The method comprises the steps that a metal net with the mesh size being 400-2,000 is adopted as a substrate, a cold spraying method is adopted, net wires of the metal net are coated with hydrophilic materials in a spraying mode, the hydrophilic materials are one or more of zinc oxide, silicon dioxide, calcium carbonate and titanium dioxide, and the grain size range is 5-200 nanometers; finally sintering is performed under the temperature of 300-750 DEG C for 60-240 min, and the oil-water separation mesh film with super-hydrophilicity and super-lipophobicity is obtained. The metal net does not need to be modified, the binding force is improved with no adhesive, no secondary pollution is generated, cleaning is easy, and the mesh film can be repeatedly used.

Owner:HEBEI UNIV OF TECH

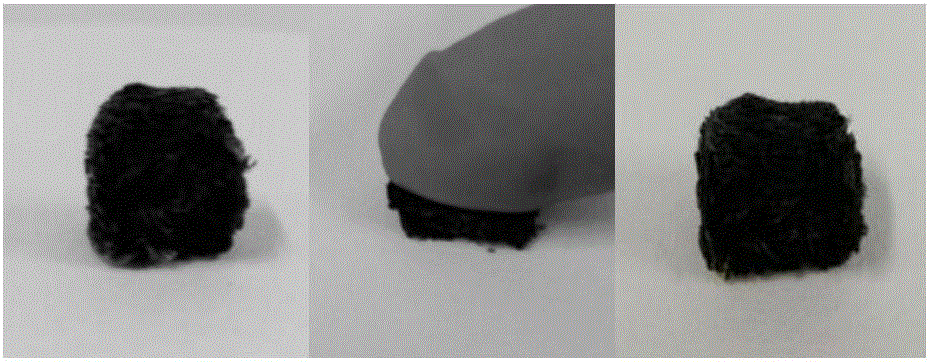

Preparation method of graphene composite foam for oil-water separation

ActiveCN106732422AAchieve separationWith underwater super oleophobic propertiesIon-exchange process apparatusFatty/oily/floating substances removal devicesFreeze-dryingAnti bacteria

The invention relates to the field of polymer materials, in particular to a preparation method of graphene composite foam for oil-water separation. The preparation method comprises the steps that reduction and crosslinking are conducted on oxidized graphene by dopamine, a hydrothermal method is used to make the oxidized graphene form a three-dimensional structure in self-assembly mode, chitosan / graphene composite foam is prepared by soaking and freeze-drying with a chitosan solution, and finally the chitosan / graphene composite foam is fluoridized to prepare the fluoridized graphene composite foam. The obtained chitosan / graphene composite foam has super amphipathicity in the air and underwater super lipophobicity, after the fluoridation, the chitosan / graphene composite foam has super hydrophobicity, and chitosan and raphene have the advantages of good flexibility, high selective separation efficiency and long cycle service life; the foam can exist stably in a corrosive medium; water takes use of gravity to go through the chitosan / graphene composite foam and does not need to be driven by external force; non-toxic biological materials such as the dopamine and the chitosan are used, the foam is green and environmentally friendly, an anti-bacteria effect of the chitosan serves as a function of purifying a water body during the oil-water separation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Perfluoro alkyl phosphoester acrylic ester and preparation thereof

InactiveCN101302232AImprove hydrophobicity and oleophobicityHigh flame retardant efficiencyAntifouling/underwater paintsPaints with biocidesPhosphateUltraviolet lights

The invention discloses perfluoroalkyl group phosphate ester acrylic ester and a method for making the same. The method comprises the following steps that: firstly, a fluoro-alcohol compound is reacted with phosphorus oxychloride and then is reacted with dibastic alcohol so as to synthesize perfluoroalkyl group phosphate ester; then, the acrylated treatment of the perfluoroalkyl group phosphate ester is carried out, or the perfluoroalkyl group phosphate ester is directly added in dibastic alcohol containing acrylic acid double bond so as to obtain perfluoroalkyl group radical which is connected with acrylic ester radical through phosphate ester bond; moreover, a molecular end contains perfluoroalkyl group phosphate ester of two acrylic ester double bonds. The method has cheap and easily obtained raw materials and simple operation, and is convenient for industrialized production; the obtained perfluoroalkyl group phosphate ester acrylic ester can be quickly solidified through adopting ultraviolet light irradiation; moreover, the obtained coating has excellent hydrophobicity and lipophobicity and high fire retardation efficiency, thereby having a broad industrial application prospect.

Owner:JIANGSU LITIAN TECH

Super-hydrophilic and underwater super-lipophobic coating and preparation method thereof

InactiveCN104629616ASimple processRaw materials are easy to getAntifouling/underwater paintsPaints with biocidesBiological adhesionZwitterion

The invention discloses a super-hydrophilic and underwater super-lipophobic coating which consists of a substrate and an organic / inorganic hybrid coating, wherein the organic / inorganic hybrid coating containing an ampholytic ionic group is coated on the surface of the substrate. 1, the method disclosed by the invention is simple in process, easy in preparation of raw materials, simple in equipment and low in cost, and the functional coating can be prepared on the surfaces of different substrates in a large area, so as to achieve super hydrophilicity and underwater super lipophobicity; and 2, by introducing a betaine-type ampholytic ionic compound of a cell outer membrane simulating molecular structure to the prepared super-hydrophilic and underwater super-lipophobic coating, the prepared functional coating not only has functions of self-cleaning, anti-fogging, underwater oil resistance and the like, but also has excellent performances of resisting biological adhesion and the like.

Owner:佛山市高明区生产力促进中心

Oil-and-water-repellent finishing agent for fabric and preparation method of oil-and-water-repellent finishing agent

The invention discloses an oil-and-water-repellent finishing agent for a fabric. The finishing agent is prepared from a perfluor acrylic emulsion, a 11-carboxyundecyl methylsilicone oil, amino silicon oil and a perfluor short-carbon chain polyacrylate emulsion. The invention also designs a preparation method of the oil-and-water-repellent finishing agent for the fabric. The perfluor acrylic emulsion, the 11-carboxyundecyl methylsilicone oil, the amino silicon oil and the perfluor short-carbon chain polyacrylate emulsion are mixed to prepare the oil-and-water-repellent finishing agent for the fabric. The preparation method is simple, feasible, environmentally friendly, and free of pollution; the prepared oil-and-water-repellent finishing agent for the fabric has excellent surface properties such as hydrophobic property, lipophobicity and antifouling property, and is good in stability; and the fabric keeps good hand feeling after being spun, and has excellent air permeability and moisture penetrability.

Owner:SUZHOU CHENHENG WEAVING

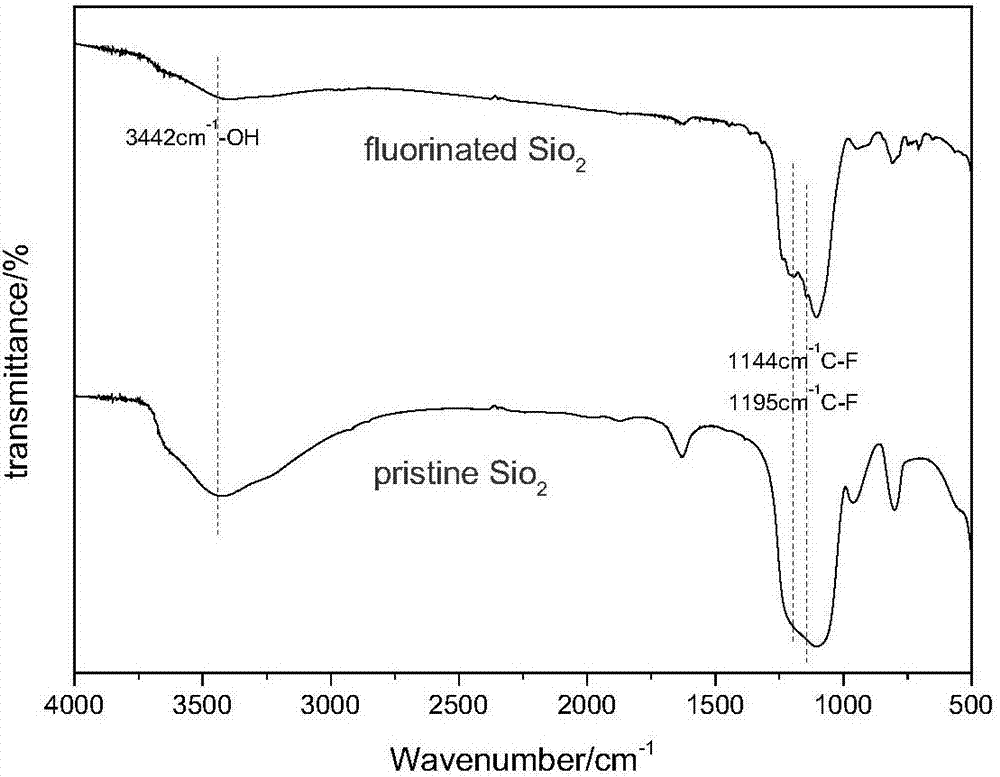

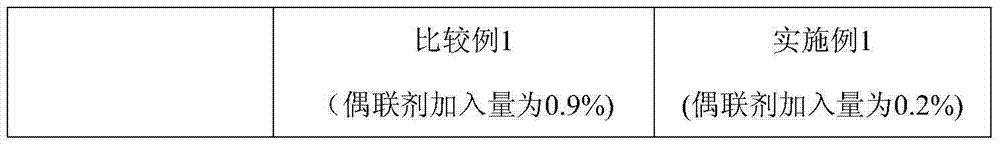

Nanopowder hydrophobicity and lipophobicity modification method

The invention relates to a nanopowder hydrophobicity and lipophobicity modification method. The nanopowder hydrophobicity and lipophobicity modification method includes firstly, mixing nanopowder with an organic solvent, and treating a mixture by an ultrasonic dispersion meter to obtain a uniform dispersed suspension; then, dropwise adding a fluorinating agent into the suspension for immersion treatment; finally, conducting spray drying to obtain modified fluorinated nanopowder. The modified nanopowder has excellent hydrophobicity and lipophobicity. The nanopowder hydrophobicity and lipophobicity modification method is simple to implement and easy for mass production.

Owner:NANJING UNIV OF TECH

Processing technology of UV-curing fluorine-containing wear-resistant hydrophobic coating

ActiveCN108587381AHas hydrophobic and oleophobic propertiesImprove waterproof performanceCoatingsWear resistantLipophobicity

The invention discloses a processing technology of a UV-curing fluorine-containing wear-resistant hydrophobic coating. The processing technology comprises the following steps: a, preparing hydrophobicnano SiO2 / TiO2 particles; b, preparing an organic silicone fluorine-containing acrylate emulsion; c, preparing a bottom-layer hydrophobic coating emulsion; e, spraying the bottom-layer hydrophobic coating emulsion; and f, spraying a surface hydrophobic coating. The processing technology disclosed by the invention has the beneficial effects that a double-layer cooperation manner of the bottom-layer hydrophobic coating and the surface hydrophobic coating is adopted, so that the coating has the properties of hydrophobicity and lipophobicity while adhesion of the waterproof coating and a target material is ensured, and water resistance of the target material is improved; the bottom-layer hydrophobic coating is cured by acrylate, so that contact strength of the bottom-layer hydrophobic coatingand the surface of the target material can be provided, and the compactness of the waterproof coating can be improved; and a structure of a nano material is stabilized through the organic silicone modified fluorine-containing acrylate, fluorine-containing silane and fluorine-containing acrylate are also used, so that hydrophobicity of the surface-layer hydrophobic coating is improved.

Owner:GUANGZHOU SUN EMPEROR INTELLIGENT TECH +1

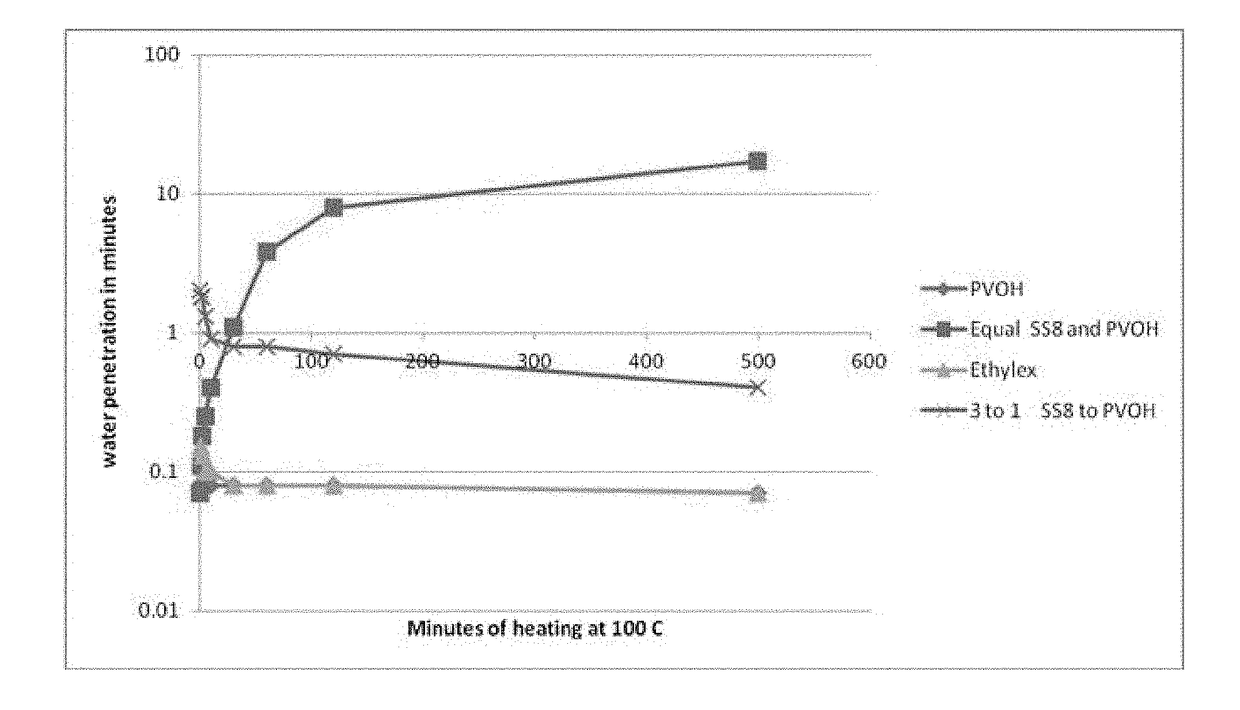

Biobased carrier coatings

The present invention describes tunable methods of treating cellulosic materials with a barrier coating comprising a prolamine and at least one polyol fatty acid ester that provides increased oil and / or grease resistance to such materials without sacrificing the biodegradability thereof. The methods as disclosed provide for adhering of the barrier coating on articles including articles comprising cellulosic materials and articles made by such methods. The materials thus treated display higher lipophobicity and may be used in any application where such features are desired.

Owner:GREENTECH GLOBAL PTE LTD

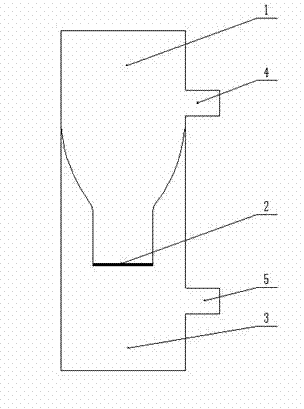

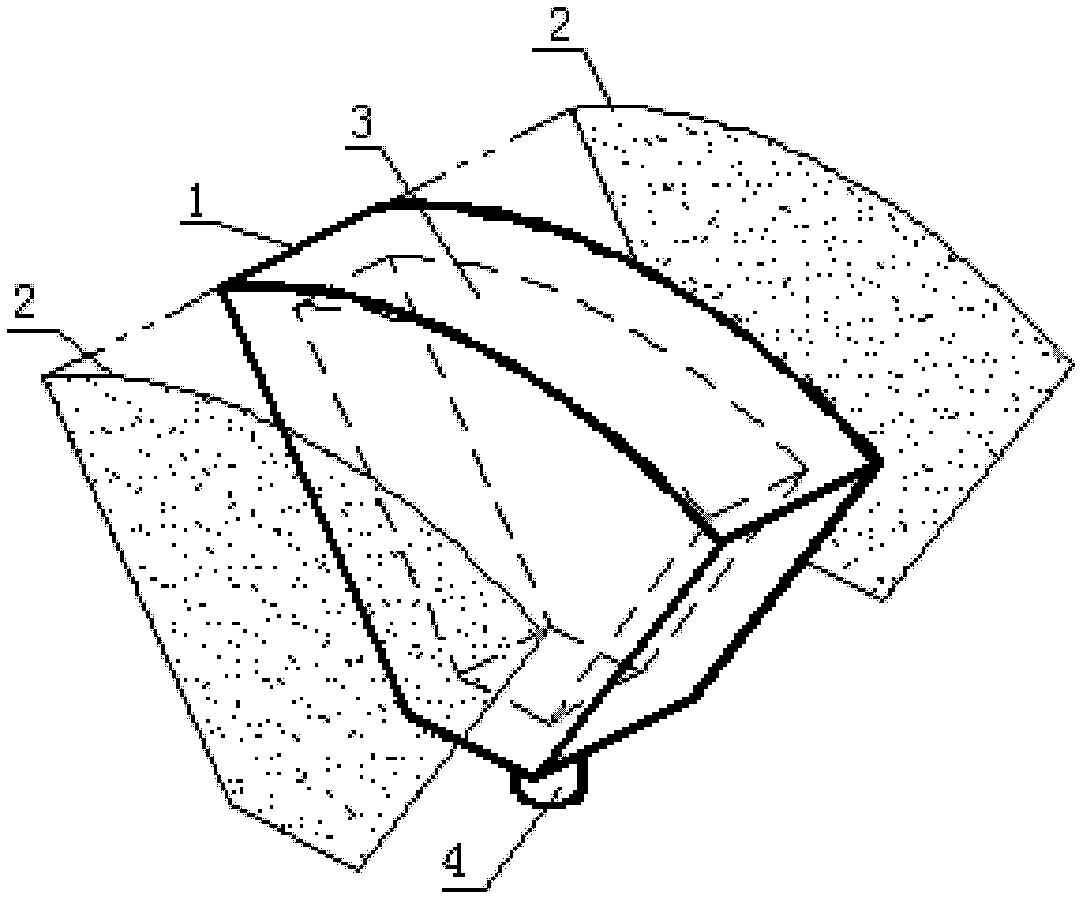

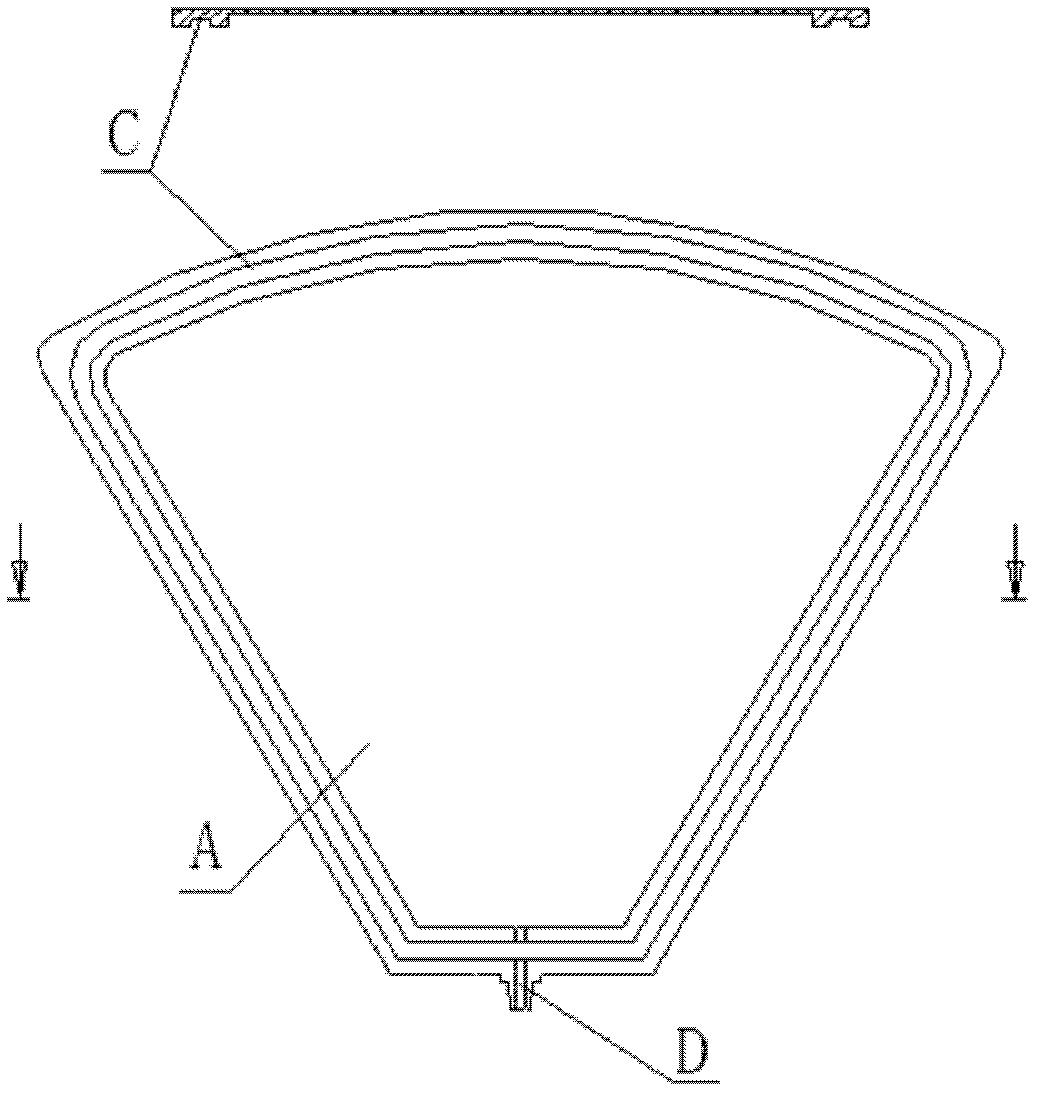

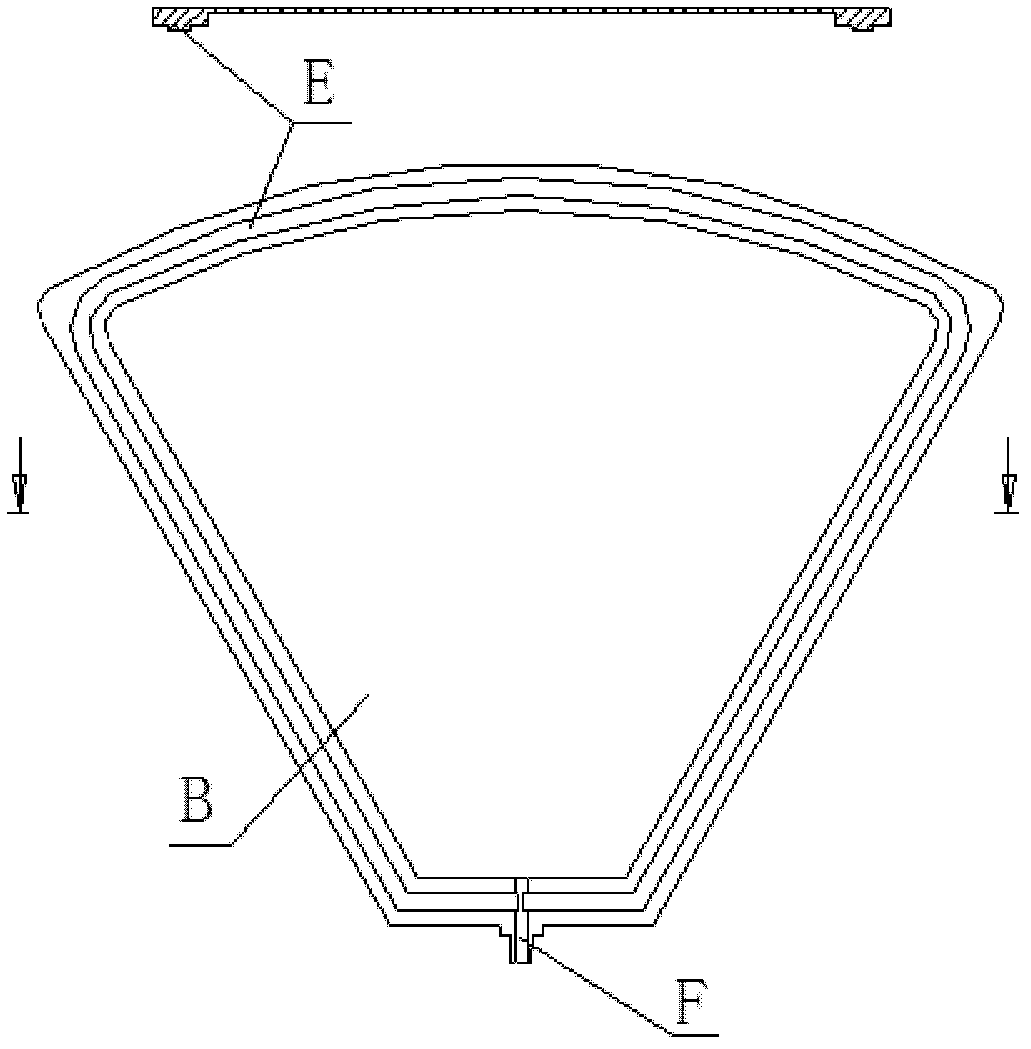

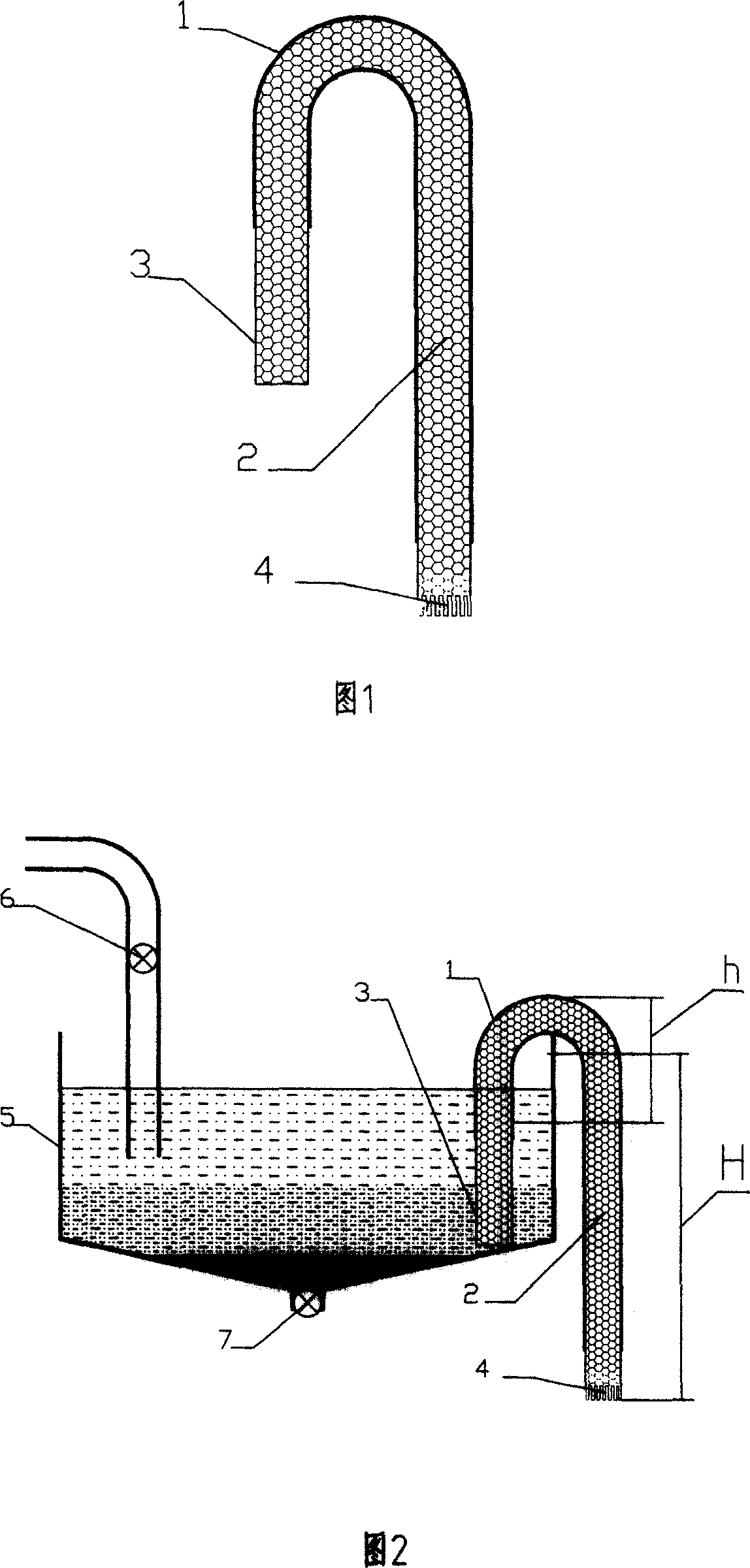

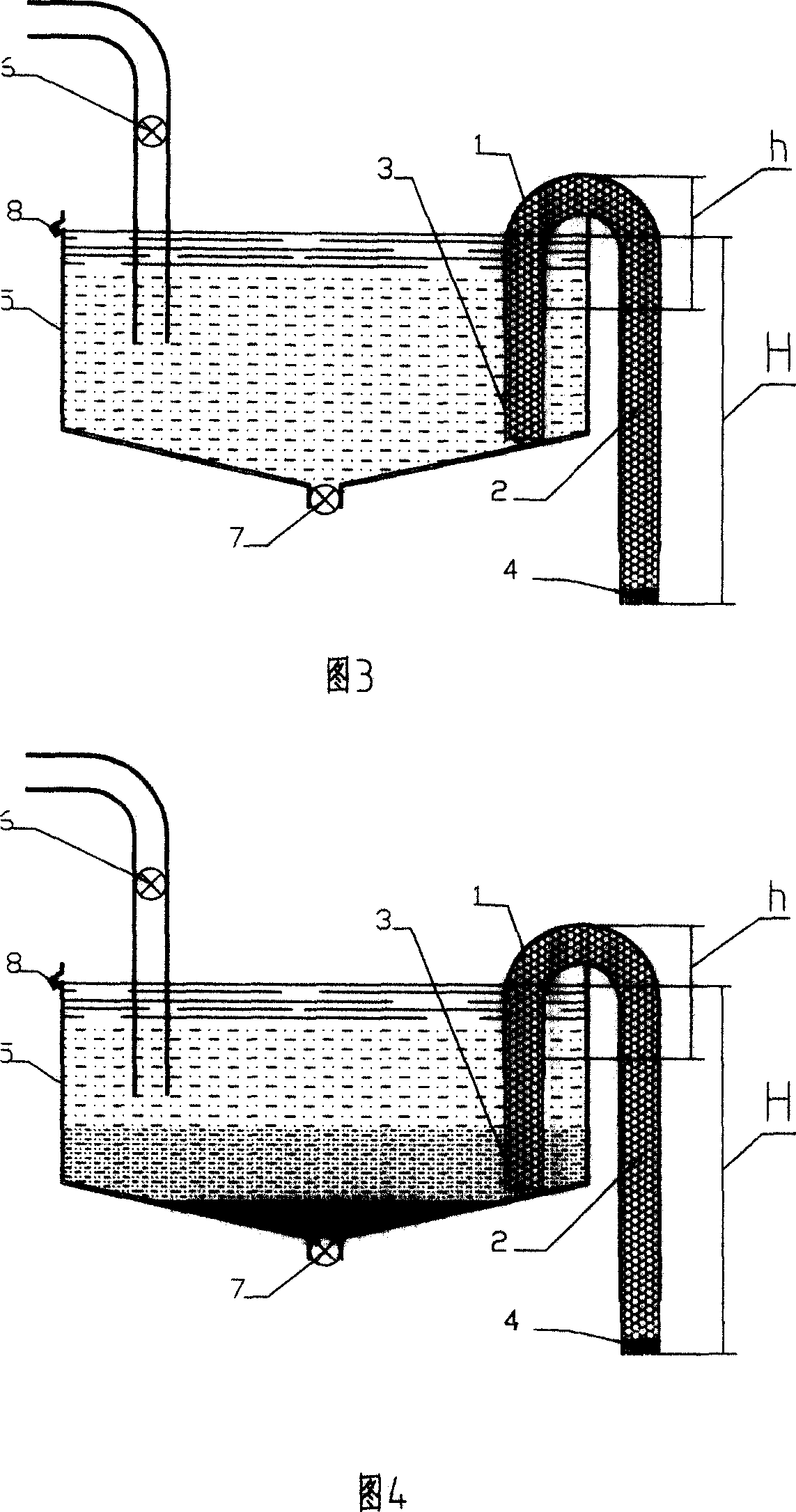

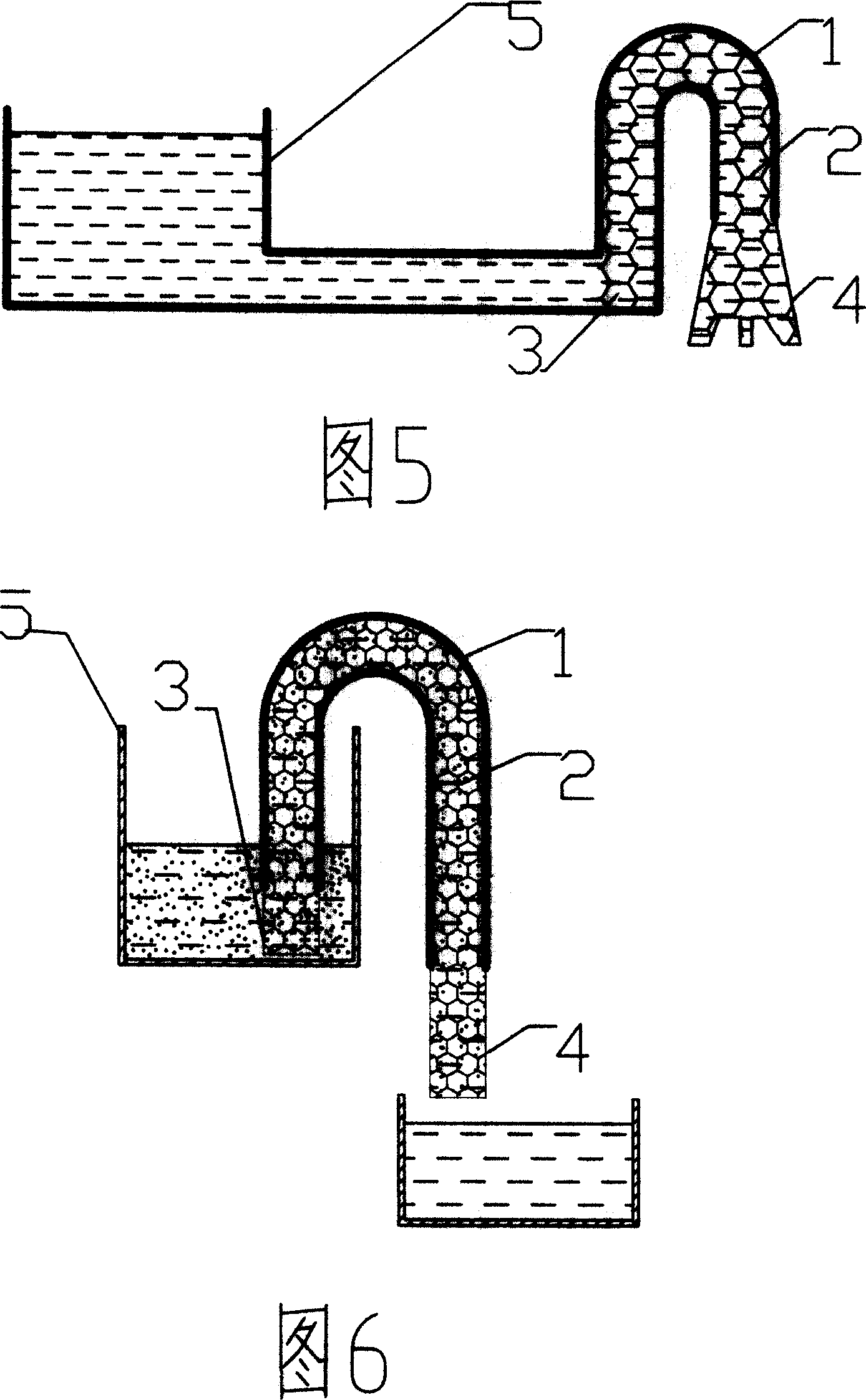

Adsorption siphon separation process and siphon separation device with self-suction function

InactiveCN101069785AImprove continuityAchieve separationSettling tanks feed/dischargeFiltration separationSiphonChemical physics

The present invention relates to an adsorption siphon separation process and a siphon separation equipment with self-absorbing function. The separation mode adopted by the invented process is a three-dimensional cross flow separation mode. It is characterized by that the required separation driving force is internal energy of adsorption material and potential energy of slurry to be separated; in the slurry container several adsorption siphon separation tubes with self-absorbing function are mounted, it utilizes the water-absorbing function and lipophobicity of its adsorption rod high water-absorbing lipophobic material, settleability of granules component and upwards floatability of oil component to implement solid-liquid and / or oil-water separation.

Owner:熊四达

Preparation method of titanate-modified nano cerium oxide/polyurethane composite paint

ActiveCN103589311AGuaranteed decentralizationGuarantee stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsPhysical chemistryCorrosion resistant

Owner:STATE GRID CORP OF CHINA +2

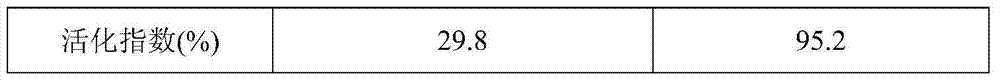

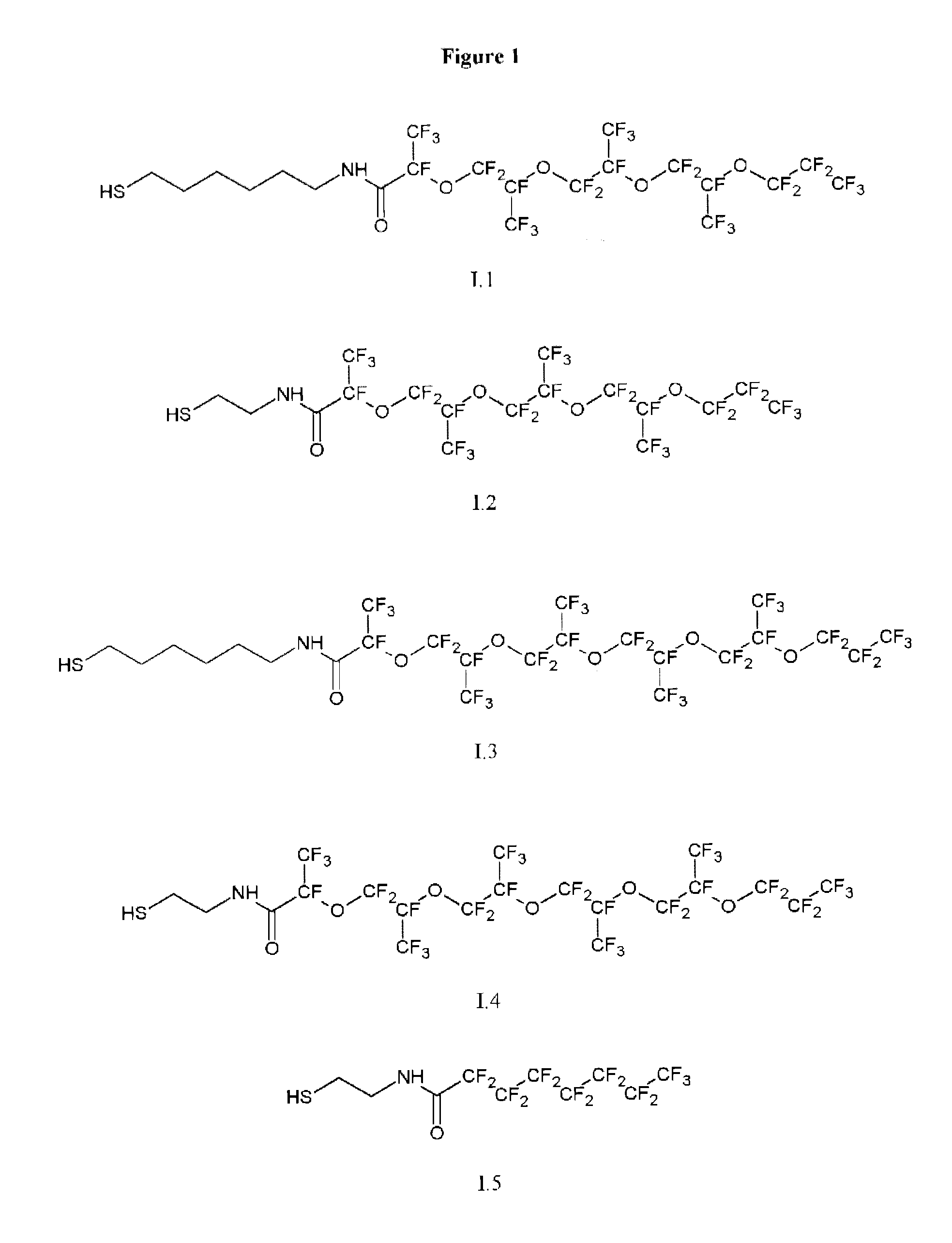

Composition for increasing the lipophobicity of a watch-making component

ActiveUS20130287955A1Satisfactory epilame effectHigh epilame efficacyOrganic chemistryOther chemical processesThiolPerfluoropolyether

The present invention describes the highly advantageous properties of a mixture of thiol-perfluoropolyether (PFPE) molecules with perfluorinated bisphosphonic (PF-BP) compounds. This mixture makes it possible in effect to obtain a lipophobic behaviour (also referred to as “epilame” effect) with common watch-making lubricants on all the materials tested, including metals, inter alia gold and alloys thereof, ceramics and semiconductors, and gives the surface treated a good resistance to ageing and to cleaning products.

Owner:ROLEX SA

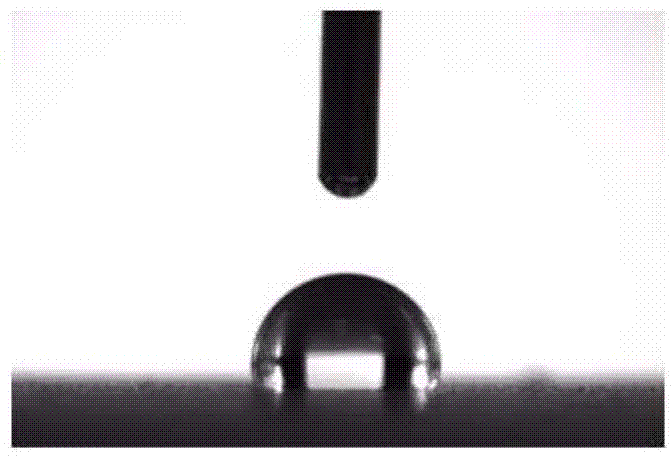

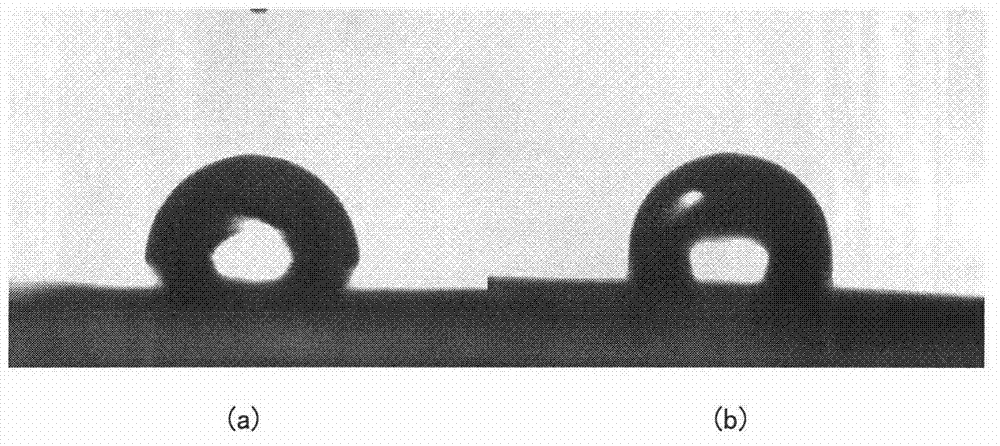

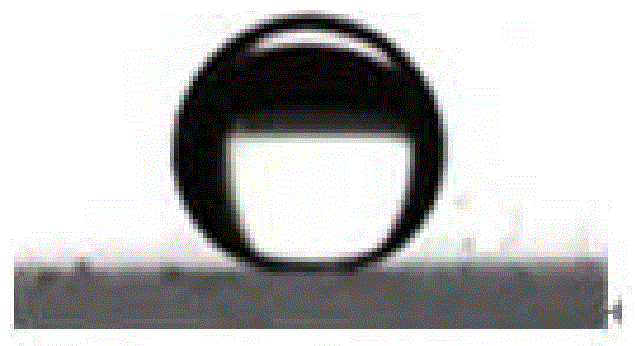

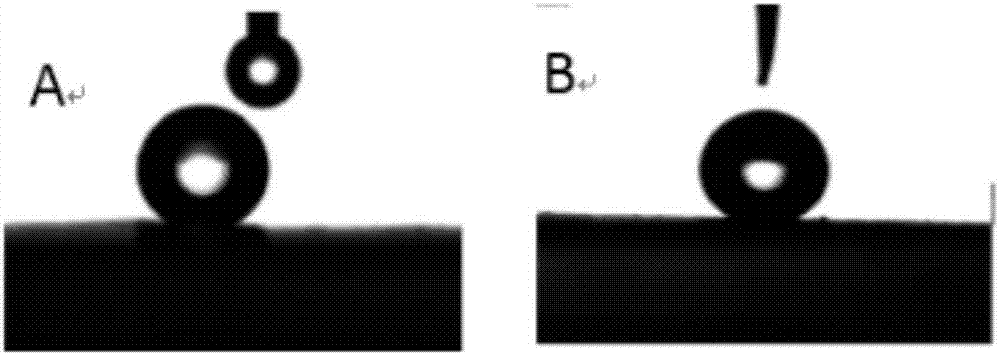

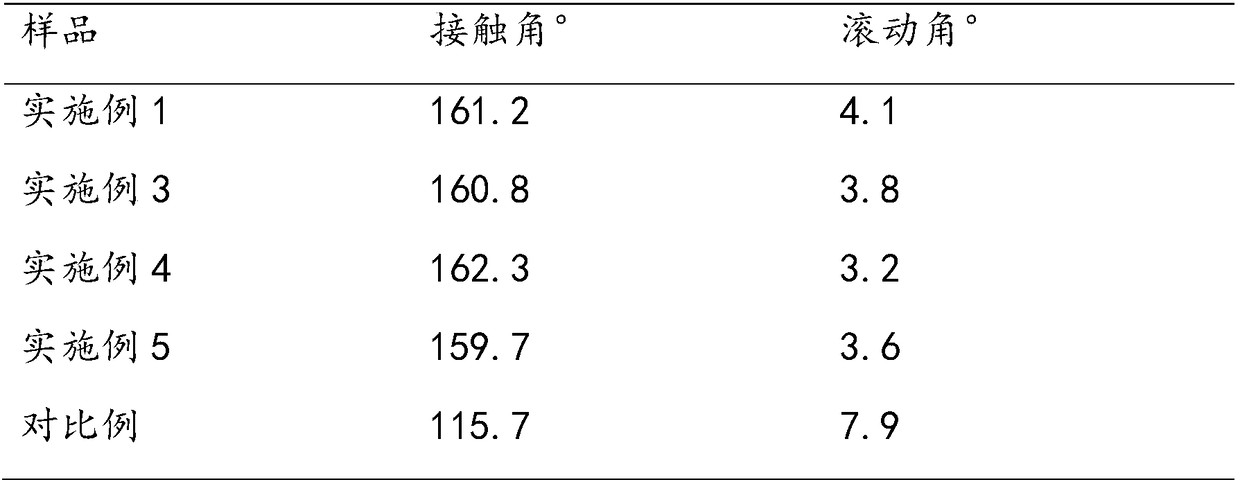

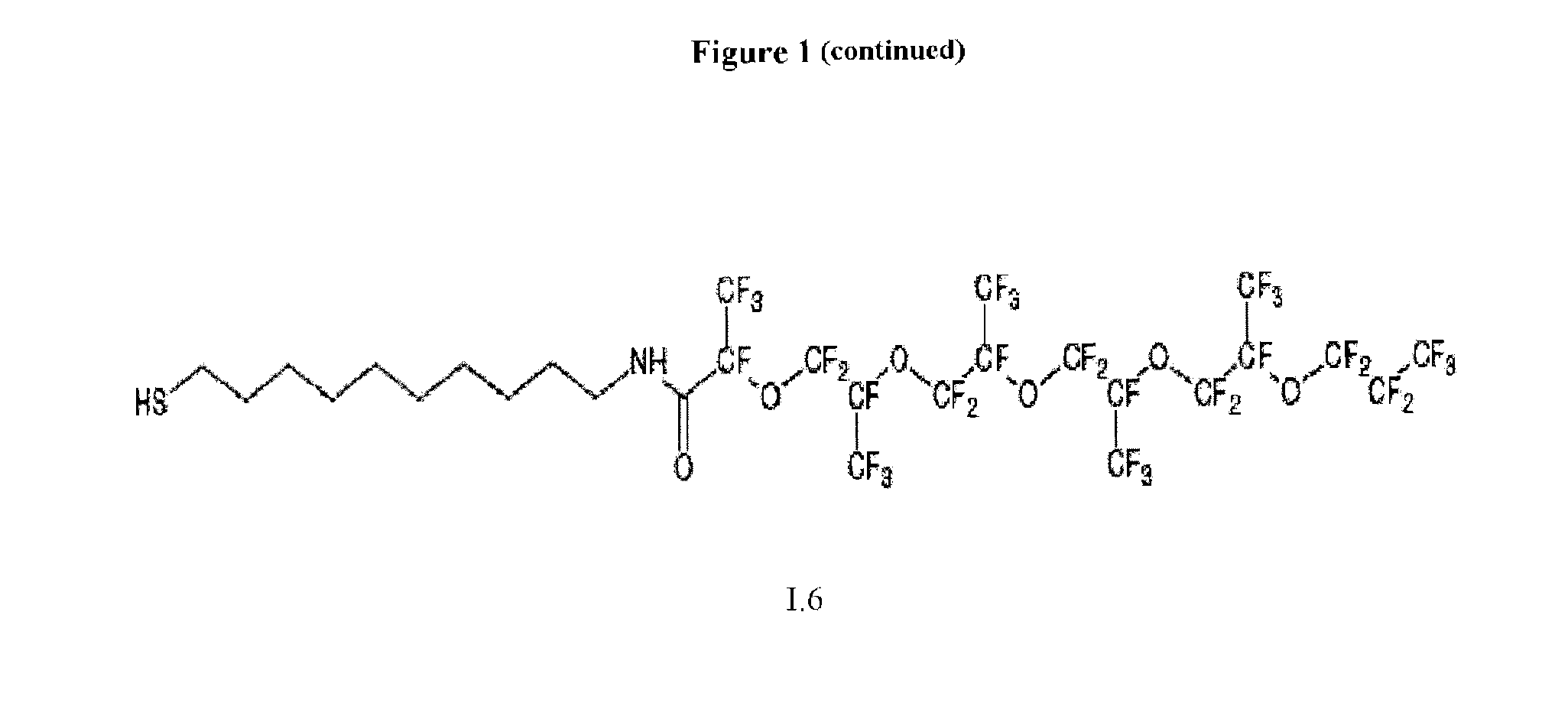

Reparation method for zinc super-hydrophobic surface

InactiveCN104195539AGood oleophobic effectSimple preparation processMetallic material coating processesPerfluorooctanoic acidNanometer size

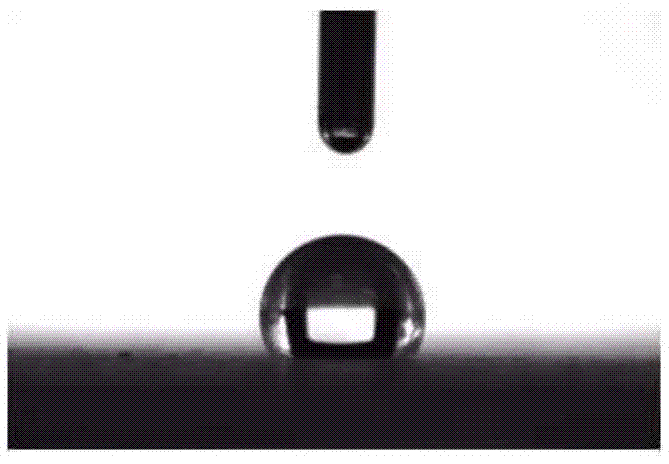

The invention discloses a technology for preparing a zinc super-hydrophobic surface. The preparation method comprises the following steps: chemically etching a zinc sheet by virtue of hydrochloric acid to form a spherical rough structure on the surface of the zinc sheet; then, performing hydrothermal reaction to form a layer of uniform rod-shaped structure which is close to nanoscale on the surface of the spherical rough structure, wherein the rod-shaped structure is almost vertical to the surface of the zinc sheet; and finally, carrying out low-energy modification by using an absolute ethyl alcohol solution of perfluoro caprylic acid to obtain the super-hydrophobic surface with good lipophobicity. According to the preparation method, distilled water drops onto the chemically-modified zinc sheet surface to carry out contact angle measurement, wherein a contact angle of the zinc sheet surface and water is greater than 150 degrees, and a rolling angle is smaller than 10 degrees; and moreover, the surface has relatively good lipophobicity, and has a contact angle of 145.62 degrees with peanut oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

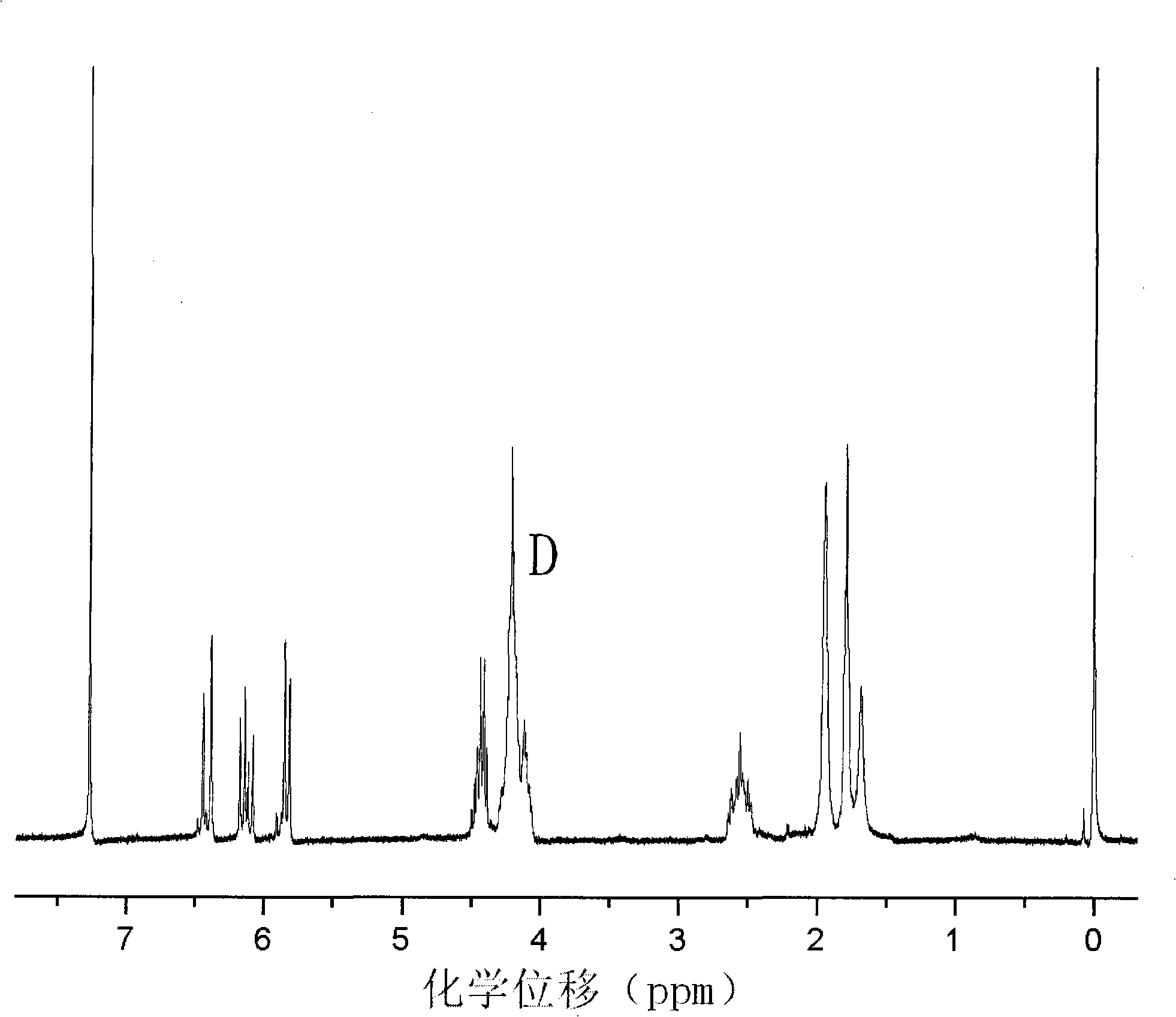

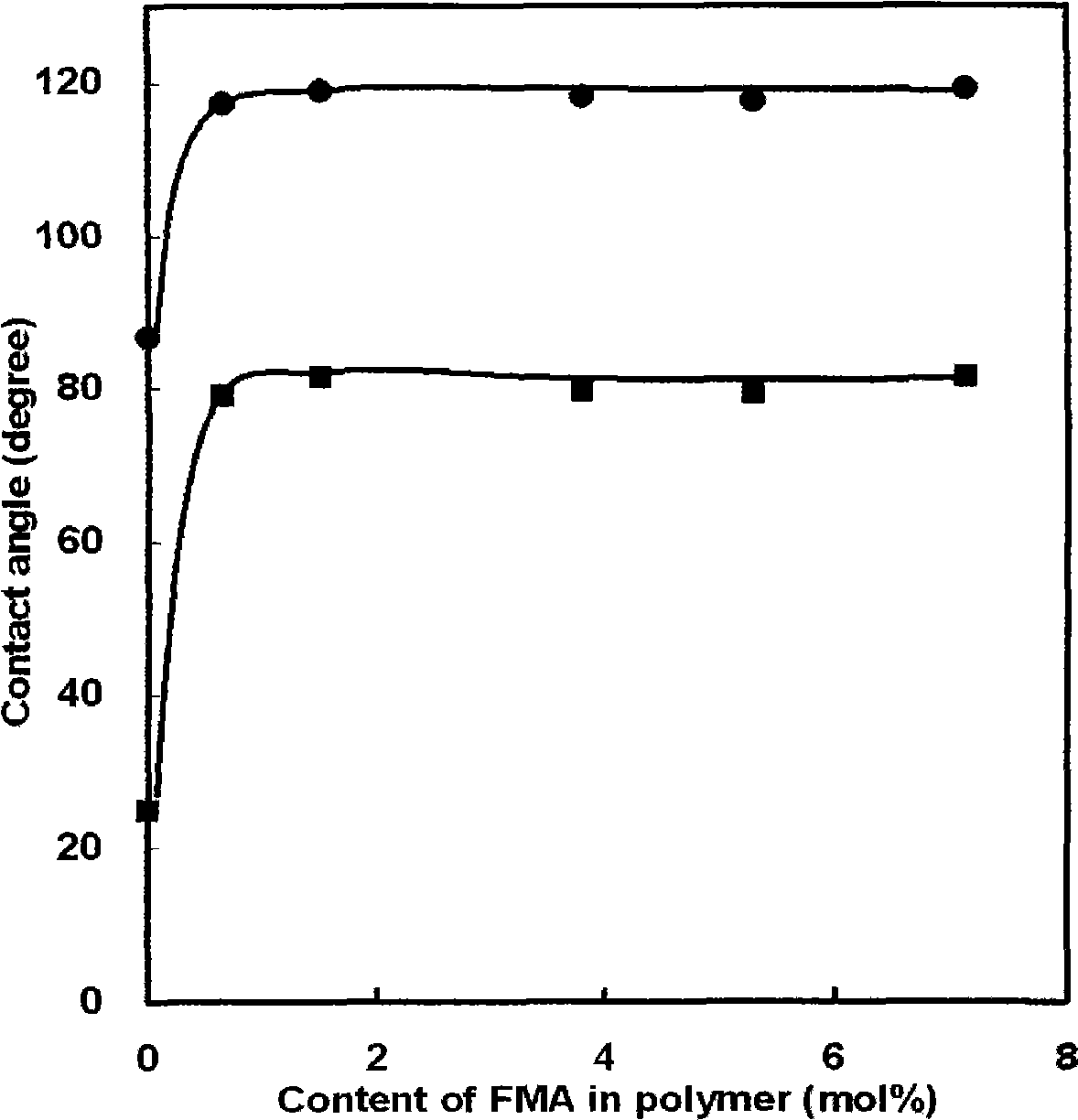

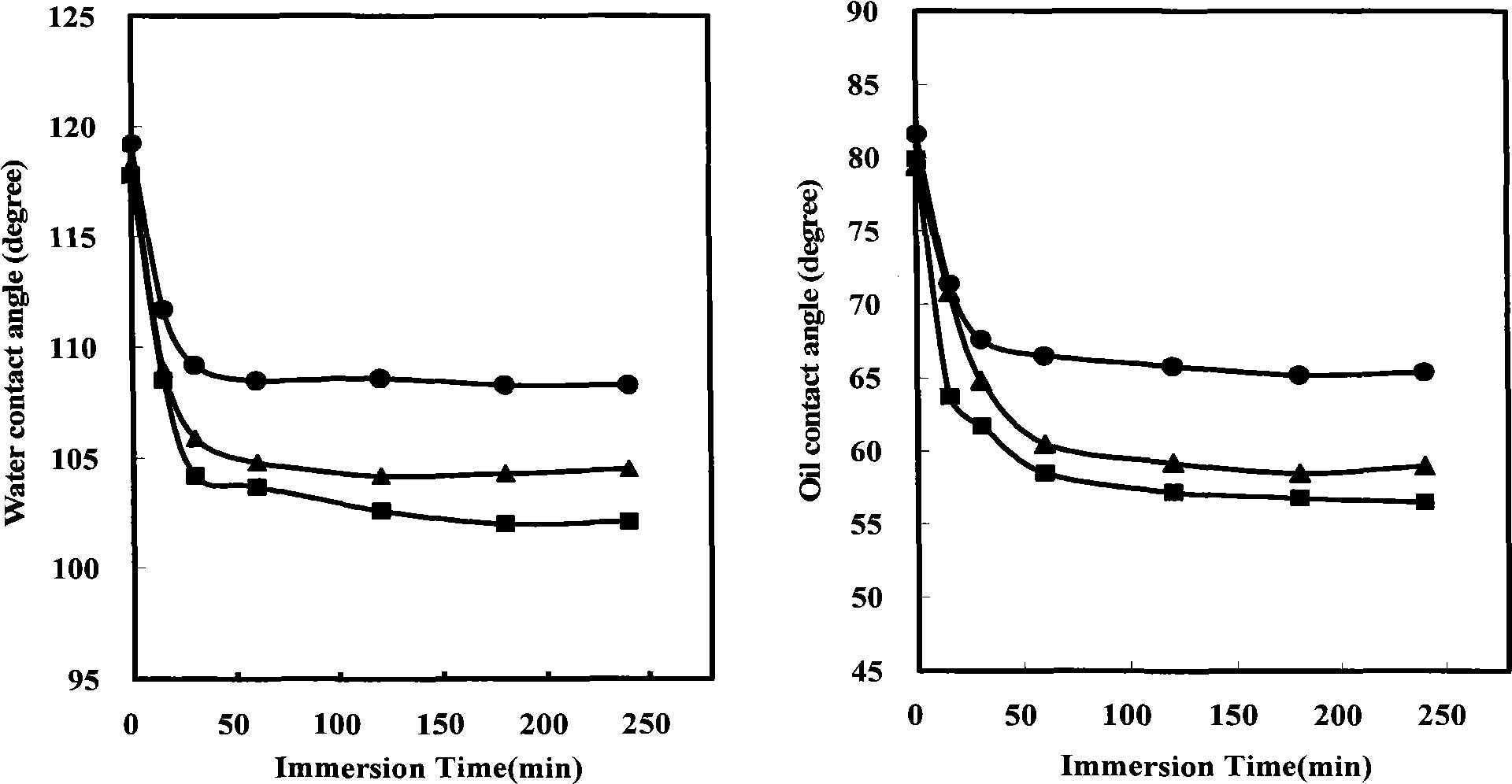

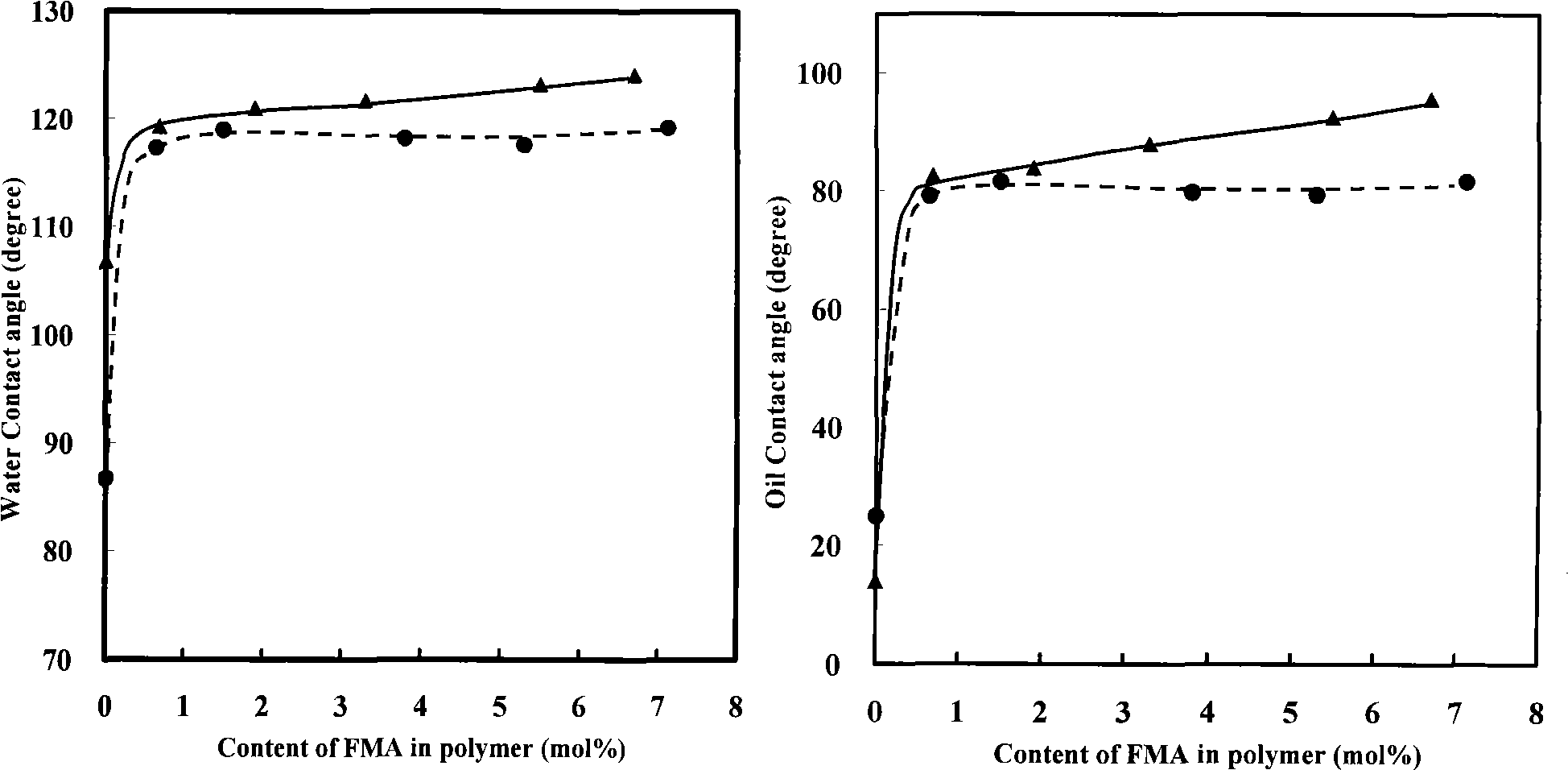

Method for preparing fluorinated acrylate copolymer

The invention discloses a method for preparing an organic polymer, in particular a method for preparing low-fluorine content, high-hydrophobicity and high-lipophobicity fluorinated acrylate copolymer. The method comprises the following steps that: monomers such as methyl methacrylate, butyl mthacrylate and octadecyl methacrylate (ODMA) are copolymerized with perfluoroalkylethyl methacrylate (FMA); an anionic emulsifier (SDS) and a non-ionic emulsifier (OP-10) form a composite emulsifier; potassium persulphate (KPS) is used as an initiator; and the fluorinated acrylate copolymer is obtained through pre-emulsion treatment, reactions under a certain temperature condition and post treatment. The method has the advantages that the copolymer prepared by the method has excellent surface performance, convenient preparation, energy conservation and environmental protection under a condition of low fluorine monomer content. The copolymer prepared by the invention has wide applications.

Owner:ZHEJIANG SCI-TECH UNIV

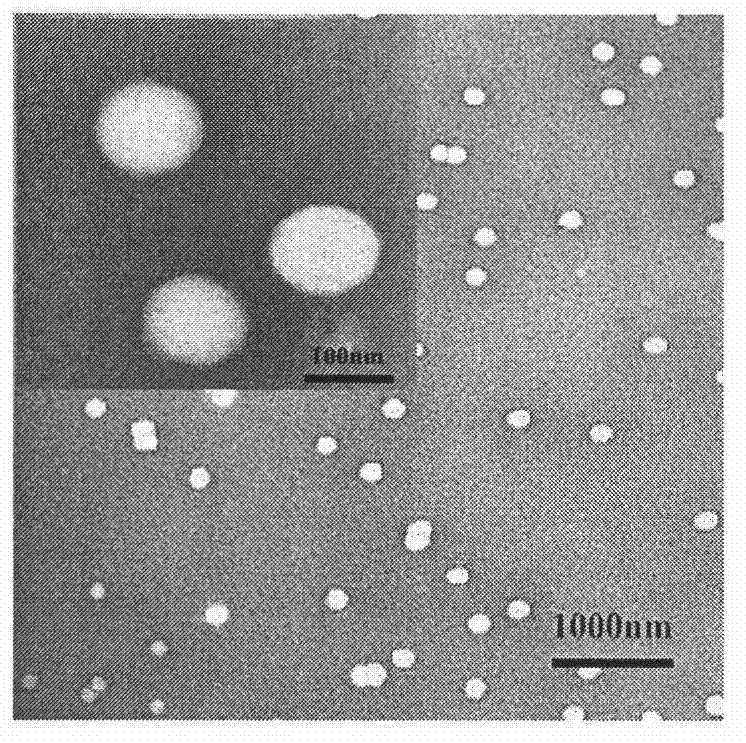

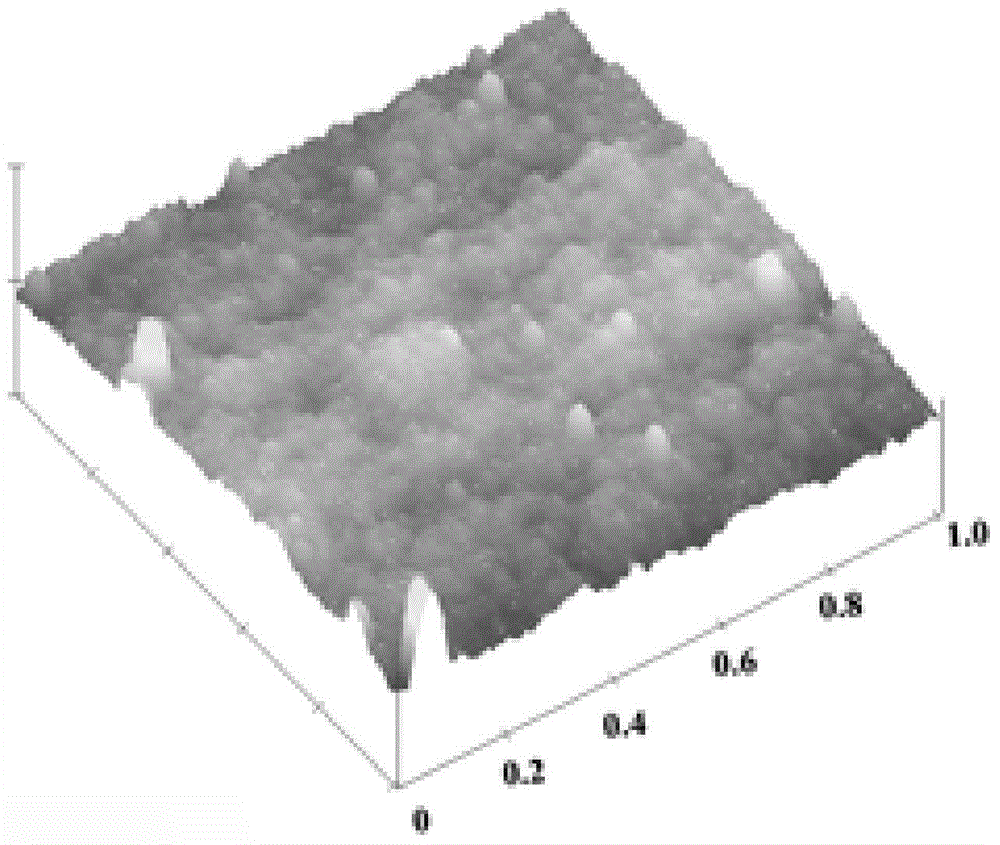

Method for preparing ultra-oleophobic surface underwater

The invention belongs to the field of surface modification of solid materials and particularly relates to a method for preparing an ultra-oleophobic surface underwater. In the method, the self-assembly technology and out-phase nucleary technology are adopted, acetic acid solution of chitosan and sodium hydroxide solution of nano-silica are used as raw materials, a surface of micro-nano composite coarse structure is prepared by a one-step method at room temperature, and a contact angle of a surface of an underwater material and oil is changed by utilizing the change of a microcosmic structure of the surface so as to change the wetting quality of the material surface. The method has simple equipment, low cost and no environmental pollution, and prepares the micro-nano composite coarse structure quickly by the one-step method at the room temperature in a large area so as to reach the underwater ultra-lipophobicity of the material surface.

Owner:DALIAN MARITIME UNIVERSITY

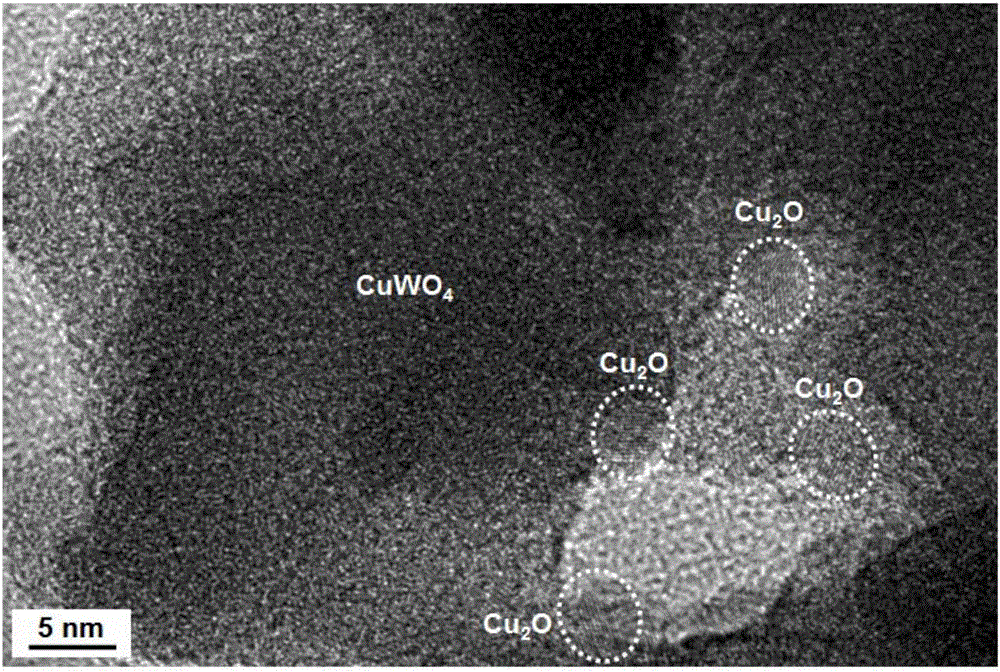

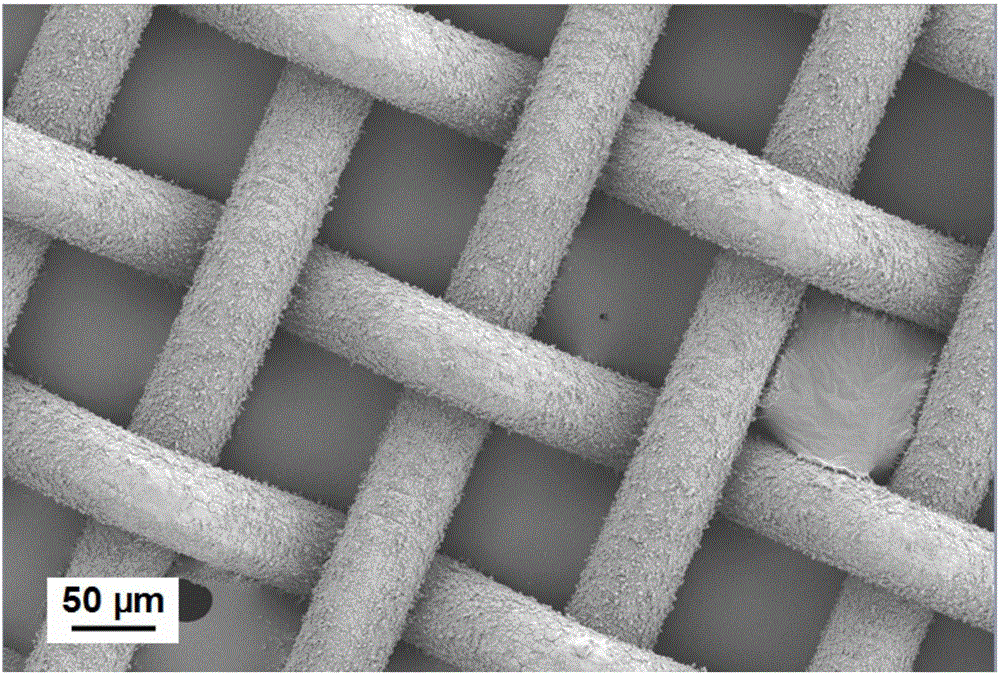

Photocatalytic oil-water separation net film, preparation method and application thereof

ActiveCN106186171AEasy to captureImprove transmission efficiencySemi-permeable membranesMembranesComposite filmElectrolysis

The invention discloses a photocatalytic oil-water separation net film, a preparation method and application thereof. The method comprises: firstly using diluted hydrochloric acid, anhydrous ethanol and deionized water to conduct ultrasonic cleaning on a copper net respectively and performing blow-drying with nitrogen; taking a tungstate solution as the electrolyte solution, using the cleaned copper net as the anode, and adopting an inert electrode as the cathode, connecting the anode and the cathode to the positive pole and negative pole of a power supply respectively, employing an anodic oxidation process to carry out constant-current electrolysis or constant-voltage electrolysis, then using deionized water to clean the anode and then performing drying, thus obtaining a copper net film covered by a cuprous oxide / copper tungstate composite film layer. The net film has super-hydrophilicity and underwater super-lipophobicity, and can efficiently separate oil-water mixtures. The invention utilizes the cuprous oxide / copper tungstate p-n junction structure to conduct photocatalytic degradation of organic pollutants in water under visible light, and realize the separation and purification of oily wastewater containing organic pollutants. The preparation process is simple, the raw materials are environment-friendly, and the cost is low.

Owner:SOUTH CHINA UNIV OF TECH

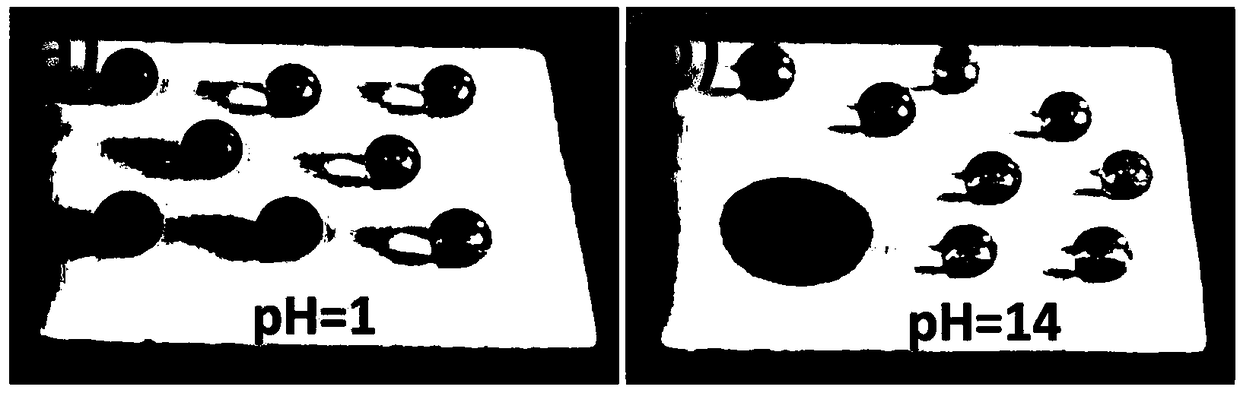

Preparation method and applications of super hydrophobic oleophobic material with pH responsiveness

ActiveCN109173345ALower free energyRich micro-nano rough structureLiquid separationSilanesThermal insulation

The invention discloses a preparation method and applications of a super hydrophobic oleophobic material with pH responsiveness. The preparation method comprises following steps: kaolin is added intoan ethanol solution of perfluorocapylic acid, after uniform mixing, an ethanol solution of silane is added, an obtained mixture is heated to 50 to 60 DEG C with stirring, thermal insulation is carriedout for 2 to 4h so as to obtain a suspending solution, the suspending solution is used for coating the surface of a substrate, and drying is carried out so as to obtain the super hydrophobic oleophobic material with pH responsiveness. The super hydrophobic oleophobic material possesses excellent super hydrophobicity and lipophobicity, and excellent wear resistance and corrosion resistance; in-suit or ex-situ pH induced material surface wetability change can be caused; a plurality of conversions between the hydrophobicity and lipophobicity can be realized. The super hydrophobic oleophobic material can be used for effective separation of a plurality of types of oil water mixtures, and especially treatment of oil-in-water emulsion, and the application prospect in treatment of leaked crude oil and purification of oil-containing waste water is promising.

Owner:西安奈微新材料有限公司

Method for synthesis of organic-inorganic composite hydrophobic/oleophobic surface treatment agent

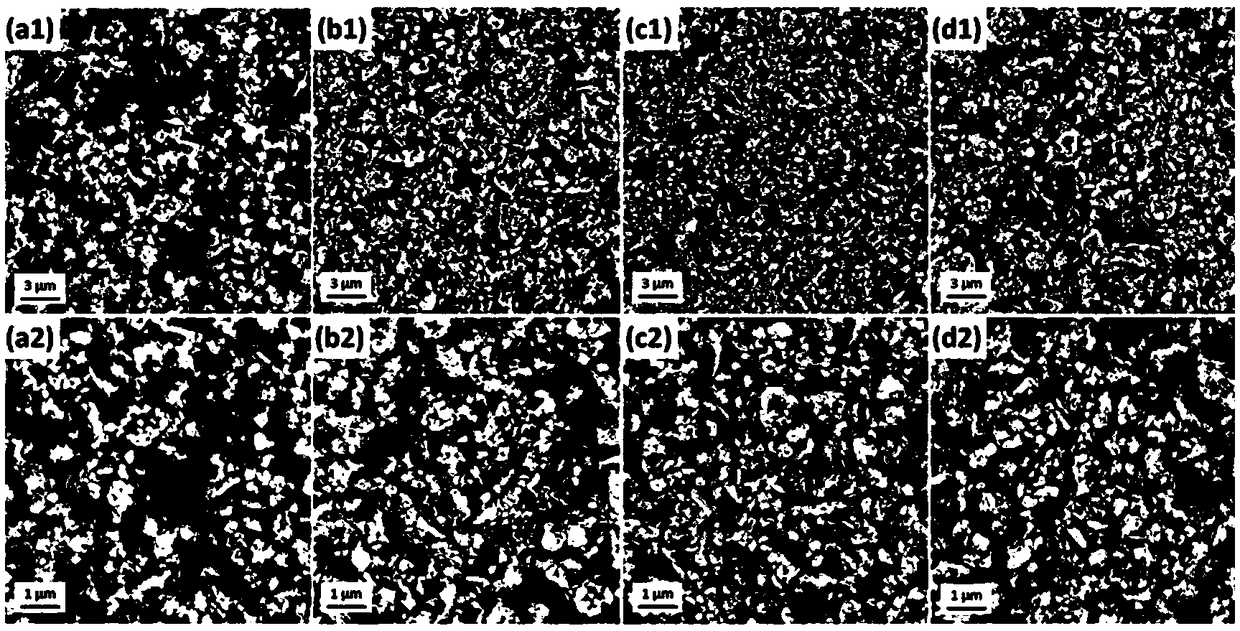

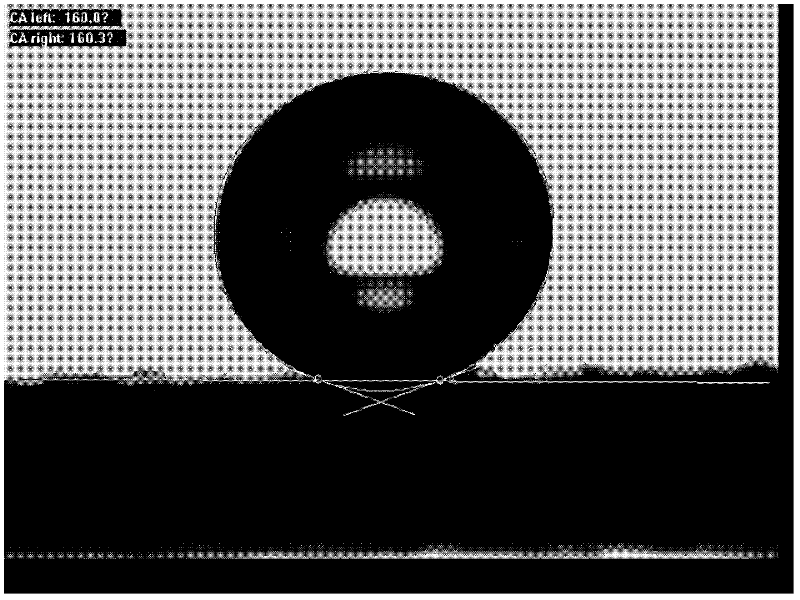

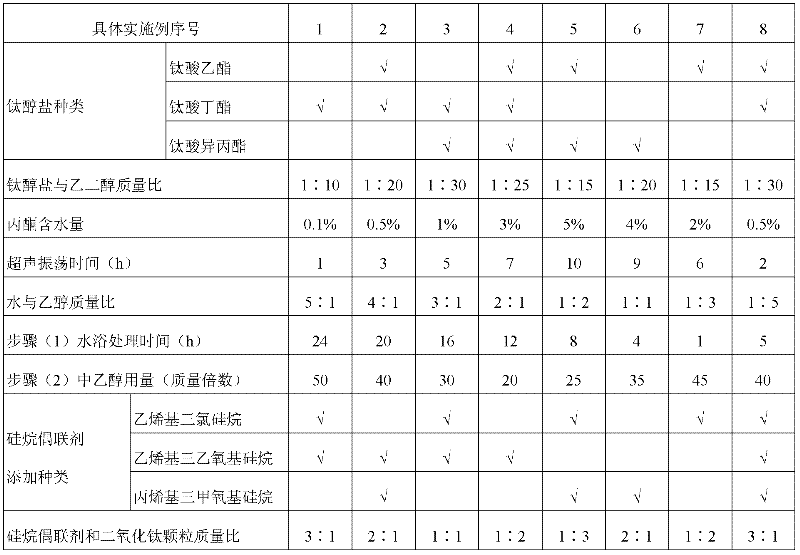

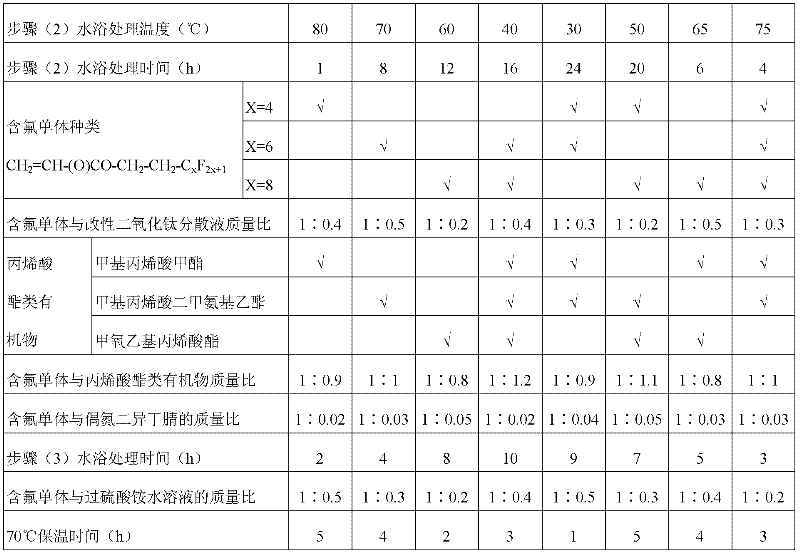

ActiveCN102352000AReduce usageAvoid adverse effects of softnessFibre treatmentTitanium dioxideWater bathsOrganic polymer

The invention relates to synthesis of hydrophobic / oleophobic surface treatment agents, and aims at providing a method for synthesis of an organic-inorganic composite hydrophobic / oleophobic surface treatment agent. The method comprises the following steps of carrying out ultrasonic vibration treatment on a mixture of at least one titanium alkoxide and glycol to obtain titanium-containing organic polymer particles, dispersing the titanium-containing organic polymer particles in water and ethanol to carry out water-bath treatment, carrying out centrifugation to obtain submicron titanium dioxide particles with a certain surface roughness, carrying out ultrasonic vibration treatment of the submicron titanium dioxide particles in ethanol, carrying out modification by at least one silane coupling agent, mixing the modified submicron titanium dioxide particles with at least one fluorine-containing monomer, at least one acrylate organic matter and azodiisobutyronitrile, after a reaction in a water bath, adding dropwisely an ammonium persulfate aqueous solution into the reaction system, and cooling to obtain the organic-inorganic composite hydrophobic / oleophobic surface treatment agent. Themethod greatly improves hydrophobicity and lipophobicity of the organic-inorganic composite hydrophobic / oleophobic surface treatment agent, and realizes a hydrophobic angle of 160 degrees and an oil-repellent level of 7. Through a cooperation enhancement effect produced by a surface structure, a fluorine-containing monomer use amount is reduced; a production cost is reduced; and adverse influences caused by overuse of fluorine-containing polymers on fabric softness are avoided effectively.

Owner:ZHEJIANG UNIV

Biobased barrier coatings comprising polyol/saccharide fatty acid ester blends

ActiveUS20200095731A1High strengthHigh surface energyCoatings with pigmentsWater-repelling agents additionCellulosePolymer science

The present invention describes tunable methods of treating cellulosic materials with a barrier coating comprising at least two polyol and / or saccharide fatty acid ester that provides increased water, oil and grease resistance to such materials without sacrificing the biodegradability thereof. The methods as disclosed provide for adhering of the barrier coating on articles including articles comprising cellulosic materials and articles made by such methods. The materials thus treated display higher hydrophobicity and lipophobicity and may be used in any application where such features are desired.

Owner:GREENTECH GLOBAL PTE LTD

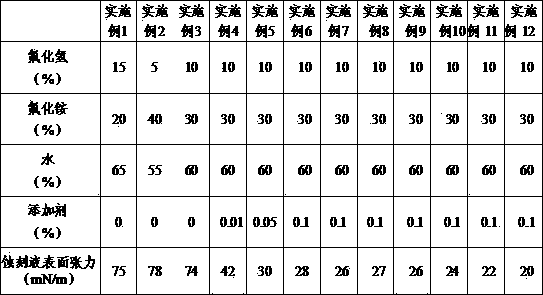

Non-ionic ammonium hydrogen fluoride etching solution with low surface tension

ActiveCN103666478AReduce surface tensionImprove permeabilitySurface treatment compositionsHigh concentrationPolyethylene glycol

The invention discloses a non-ionic ammonium hydrogen fluoride etching solution with low surface tension. The non-ionic ammonium hydrogen fluoride etching solution consists of hydrogen fluoride, ammonium fluoride, an additive and deionized water, wherein preferably, the additive is selected from one or more of polyethylene glycol monoperfluorononylene ether, perfluorohexane sulfonic acid polyglycerol ester, octylamine, polyglycerol perfluorononylene ether, polyethylene glycol perfluorononylene methyl ether, and perfluorohexane sulfonic acid macrogol ester. A proper additive is added on the basis of the hydrogen fluoride etching solution in the prior art and can be dissolved into high-concentration hydrogen fluoride and ammonium fluoride without introducing any metal ion or negative ion, so that residues on the surface of an etched oxide layer are eliminated, low surface tension is achieved for the etching solution, the permeability of the etching solution is increased, and the etching solution can enter a pore of which the pore diameter is 2.5 mu m; the fluorocarbon chain of a fluorine surfactant in a surfactant composition has the properties of high surface activity, hydrophobicity and lipophobicity, so that the surface tension of the solution can be reduced greatly, the using amount of the etching solution is small, and the production cost is low.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

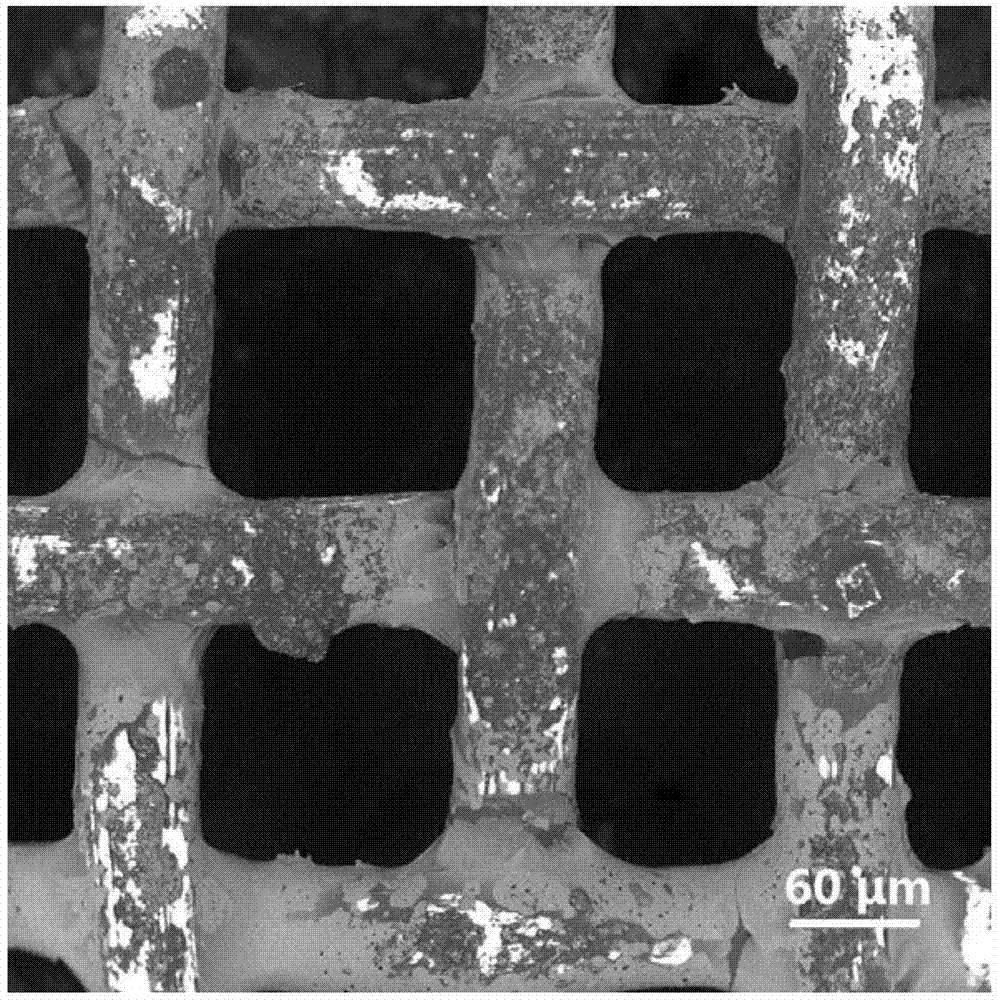

Preparation method of intelligent oil-water separation membrane with stain-resistant performance

InactiveCN108744598AImprove adhesionImprove mechanical durabilitySemi-permeable membranesMembranesMetal fiberMicro nano

The invention discloses a preparation method of intelligent oil-water separation membrane with stain-resistant performance. Through etching and chemical deposition, a micro-nano layered structure is constructed on the surface of a stainless steel fiber mat with a 3D-net porous structure, the prepared stainless steel fiber mat is prone to be wet by water and oil, and after water is used for pre-wetting, the metal fiber mat shows the performance of super-hydrophilicity and super-lipophobicity in an oil-water mixture; while after oil is used for pre-wetting, the metal fiber mat shows the performance of super-lipophilicity and super-hydrophobicity in the oil-water mixture, and the prepared stainless steel fiber mat oil-water separation membrane can be used for separating oil-water mixtures ofmany types. The preparation method of the intelligent membrane which has the advantages of good durable performance and mechanical performance, high flux, high separation efficiency, stain resistant,low cost, easiness of industrialize and capability of continuous oil-water mixture separation is provided.

Owner:洛阳纳诺环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com