Preparation method and hydrophobic anti-icing application of POSS (polyhedral oligomeric silsesquioxane) crosslinking modified fluorine-silicon coating

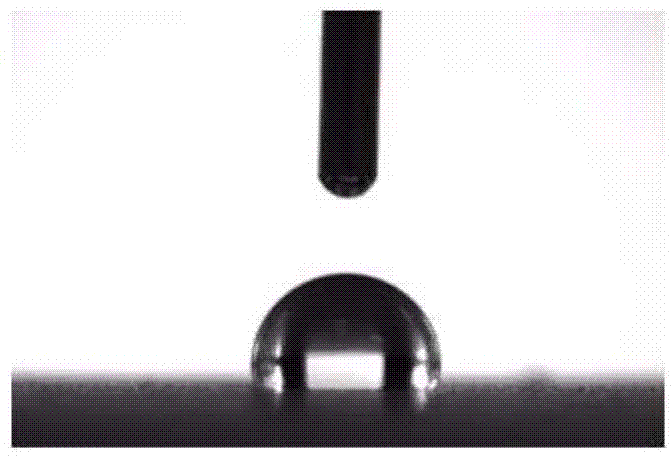

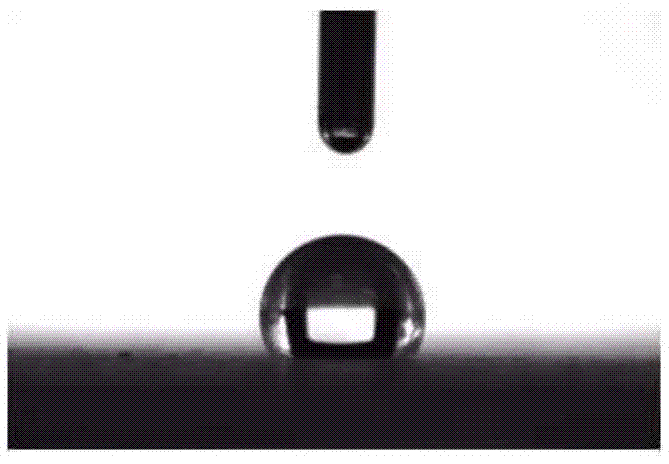

A cross-linking modification and coating technology, applied in the direction of coating, etc., to achieve the effect of simple operation, good hydrophobicity and anti-icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Synthesis of fluoroalkylpolysiloxane

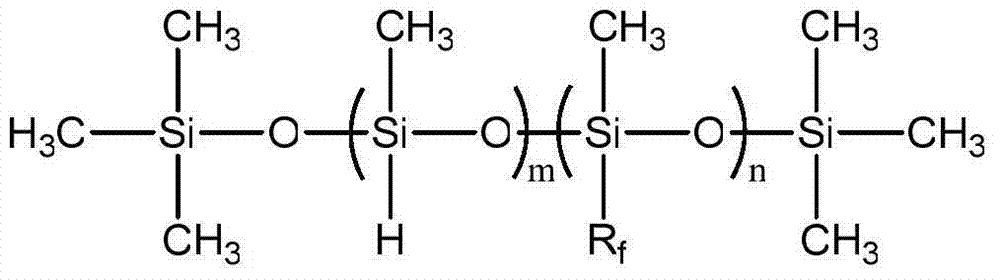

[0040] Weigh 5.0g polymethylhydrogensiloxane (hydrogen content 0.75wt%), 2.8g hexafluorobutyl methacrylate (Si-H to C=C molar ratio=1:0.3), 31.2g trifluorotoluene (concentration is 20wt%) is added in the 250mL four-neck flask that is equipped with condenser tube, thermometer, blows nitrogen gas 30 minutes and removes the air in bottle completely, is warming up to 30 ℃ under nitrogen protection, adds 50 μ L chloroplatinic acid catalyst (5g / L isopropanol solution, 50ppm), and reacted for 2 hours under slow magnetic stirring. After the temperature of the reactant was stabilized, the temperature was raised to 80°C, and the speed of magnetic stirring was accelerated for constant temperature reaction for 24 hours. After being treated in a vacuum oven at 40°C for 12 hours, the residual solvent and unreacted monomers were completely removed to obtain hexafluorobutyl methacrylate-based polysiloxane, whose structural formula is

[0041]...

Embodiment 2

[0055] (1) Synthesis of fluoroalkylpolysiloxane

[0056] Weigh 5.0g polymethylhydrogensiloxane (hydrogen content 0.75wt%), 4.7g hexafluorobutyl methacrylate (Si-H to C=C molar ratio=1:0.5), 38.8g trifluorotoluene (Concentration is 20wt%) is added in the 250mL four-necked flask that is equipped with condenser tube, thermometer, blows nitrogen gas 30 minutes and removes the air in the bottle completely, under the protection of nitrogen, heats up to 30 ℃, adds 100 μ L Karstedt catalyst (5 g / L isopropyl Alcohol solution, 100ppm), react under slow magnetic stirring for 2h, after the temperature of the reactant is stable, raise the temperature to 80°C, speed up the magnetic stirring speed and keep the temperature for 24h, after the reaction is completed, use a rotary evaporator to remove the reaction solvent, and then pass through a vacuum drying oven After treatment at 40°C for 12 hours, the residual solvent and unreacted monomers are completely removed to obtain hexafluorobutyl me...

Embodiment 3

[0071] (1) Synthesis of fluoroalkylpolysiloxane

[0072] Weigh 5.0g polymethylhydrogensiloxane (hydrogen content 0.75wt%), 8.7g trifluorooctyl methacrylate (Si-H and C=C molar ratio=1:0.5), 54.8g trifluoro Add toluene (concentration is 20wt%) in the 250mL four-necked flask that is equipped with condensing tube, thermometer, pass nitrogen gas for 30 minutes to remove the air in the bottle, heat up to 40 ℃ under the protection of nitrogen, add 150 μ L chloroplatinic acid catalyst (5g / L of tetrahydrofuran solution, 150ppm), reacted under slow magnetic stirring for 3h, after the temperature of the reactant was stabilized, the temperature was raised to 100°C, and the speed of magnetic stirring was accelerated for constant temperature reaction for 24h. After treatment at 70°C in a drying oven for 24 hours, the residual solvent and unreacted monomers were completely removed to obtain trifluorooctyl methacrylate polysiloxane, whose structural formula is

[0073]

[0074] Wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com