Preparation method of oil-water separation net membrane with super-hydrophilic lipophobicity

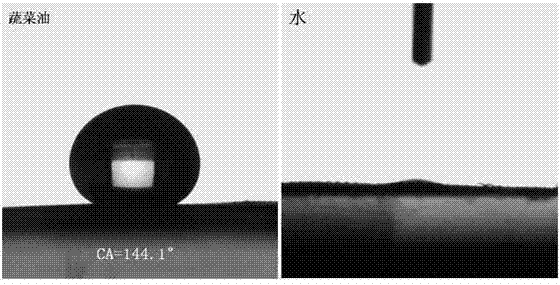

An oil-water separation mesh and super-hydrophilic technology, which is applied in the chemical industry and functional materials, and chemical fields, can solve the problems of oil-water separation membranes that are difficult to recycle, affect oil penetration, and high water density, and achieve short time consumption and reusability Good and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

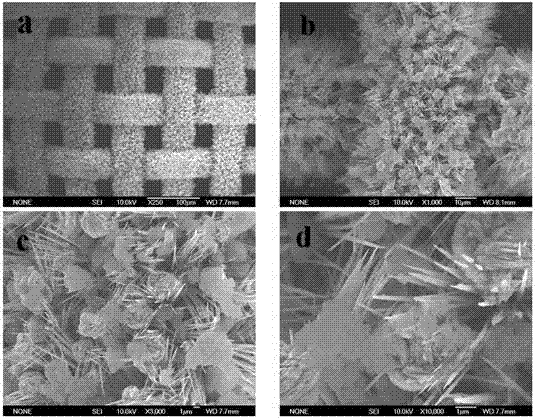

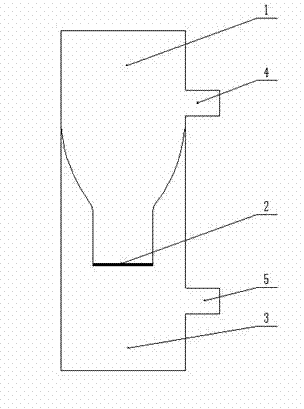

[0020] A method for preparing an oil-water separation mesh with superhydrophilic and oleophobic properties. The copper mesh is used as the base, and the micro-nano structure is constructed by a simple solution immersion method, and polydimethyldiallylammonium chloride-sodium perfluorooctanoate is used to / Silicon dioxide (PDDA-PFO / SiO 2 ) complex for surface modification, the steps are as follows:

[0021] 1) Cut out 5×5 cm 2 The 300-mesh copper mesh was used as the substrate, and ultrasonically cleaned with detergent, ethanol solution with a concentration of 50 w%, absolute ethanol, and deionized water in sequence. The ultrasonic cleaning time was 10 min each time, and the cleaned copper mesh was placed in the drum Dry in the air drying oven for 2 hours for subsequent use;

[0022] 2) Prepare 0.2M NaOH aqueous solution and 0.1M K respectively 2 S 2 o 8 Aqueous solution, NaOH aqueous solution and K 2 S 2 o 8 The aqueous solution is ultrasonically mixed according to the...

Embodiment 2

[0031] A method for preparing an oil-water separation mesh with superhydrophilic and oleophobic properties. The copper mesh is used as the base, and the micro-nano structure is constructed by a simple solution immersion method, and polydimethyldiallylammonium chloride-sodium perfluorooctanoate is used to / Silicon dioxide (PDDA-PFO / SiO 2 ) complex for surface modification, the steps are as follows:

[0032] 1) Cut out 5×5 cm 2 The 300-mesh copper mesh was used as the substrate, and ultrasonically cleaned with detergent, ethanol solution with a concentration of 50 w%, absolute ethanol, and deionized water in sequence. The ultrasonic cleaning time was 10 min each time, and the cleaned copper mesh was placed in the drum Dry in the air drying oven for 2 hours for subsequent use;

[0033] 2) Weigh 8g NaOH and 2.7g K with a precision electronic balance 2 S 2 o 8 , take two parts of 100ml deionized water with a measuring cylinder, pour it into a 250ml beaker, and mix the weighed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com