Super-hydrophilic and underwater super-lipophobic coating and preparation method thereof

An underwater super-oleophobic and super-hydrophilic technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve problems such as complex process, high cost, and poor anti-bioadhesion performance , to achieve the effect of simple process, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Dissolve 5.0 g of alkoxysilane-functionalized betaine-type zwitterionic compound in 95.0 g of ethanol at room temperature, adjust the pH of the solution to 2 with 0.1 M hydrochloric acid solution, and hydrolyze and age for 4 hours to obtain A solution;

[0039] (2) adding 5.0 g of nano silicon dioxide with a size of 50 nm into 95.0 g of methanol solvent to obtain B solution;

[0040] (3) At room temperature, mix 10.0g of A solution, 2.0g of B solution, 0.2g of isopropanol, 0.1g of water and 2g of ethyl orthosilicate and stir evenly to obtain a mixed solution;

[0041] (4) Clean the glass surface and dry it at normal temperature;

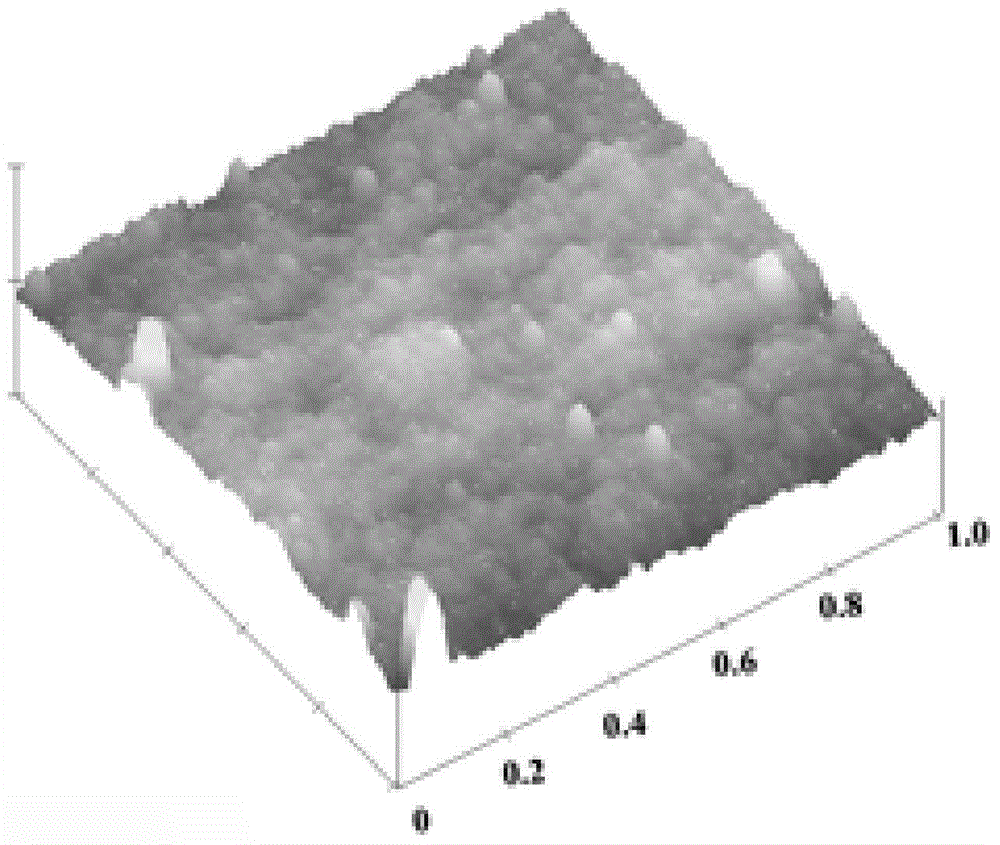

[0042] (5) Apply the mixed solution of step (3) to the clean glass surface by spraying, and place it at 80°C for 30 minutes to obtain a super-hydrophilic and underwater super-oleophobic coating. The three-dimensional surface of the coating Microstructure as attached figure 1 shown.

[0043] The thickness of the prepared coating is 10 μm...

Embodiment 2

[0048] (1) Dissolve 5.0 g of alkoxysilane-functionalized betaine-type zwitterionic compound in 450.0 g of methanol at room temperature, adjust the pH of the solution to 5 with 0.1 M hydrochloric acid solution, and hydrolyze and age for 1 hour to obtain A solution;

[0049] (2) adding 5.0 g of nano silicon dioxide with a size of 100 nm into 450.0 g of ethanol solvent to obtain B solution;

[0050](3) At room temperature, mix 50.0 g of A solution, 1.0 g of B solution, 0.2 n-butanol, and 0.1 g of water and stir evenly to obtain a mixed solution;

[0051] (4) Clean the glass surface and dry it at normal temperature;

[0052] (5) Using the method of shower coating, apply the mixed solution of step (3) to the clean glass surface, and place it at 160°C for 100 minutes to obtain a super-hydrophilic and underwater super-oleophobic coating. The three-dimensional microstructure is attached Figure 6 shown.

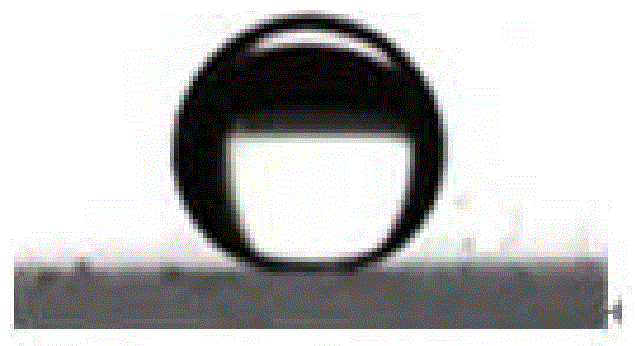

[0053] The thickness of the prepared coating is 100 μm, and the contact angle...

Embodiment 3

[0058] (1) Dissolve 20.0 g of alkoxysilane-functionalized betaine-type zwitterionic compounds in 95.0 g of methanol at room temperature, adjust the pH of the solution to 7 with 0.1 M hydrochloric acid solution, and hydrolyze and age for 5 hours to obtain a solution;

[0059] (2) adding 5.0 g of nano silicon dioxide with a size of 50 nm into 145.0 g of isopropanol solvent to obtain B solution;

[0060] (3) At room temperature, mix 10.0g of A solution, 20.0g of B solution, 10.0g of water and 2g of methyl orthosilicate and stir evenly to obtain a mixed solution;

[0061] (4) Clean the glass surface and dry it at normal temperature;

[0062] (5) Apply the mixed solution in step (3) to a clean glass surface by spraying, and place it at 120°C for 30 minutes to obtain a superhydrophilic and underwater superoleophobic coating.

[0063] The thickness of the prepared coating is 50 μm, and the contact angle of the surface with water in air is 3°; the contact angle with hexadecane under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com