Preparation method for core-shell fluorinated polyurethane-acrylate latex

A technology of acrylate and polyurethane is applied in the field of preparation of latex of elastic paint for exterior walls that is resistant to stains, can solve problems such as low grafting rate, etc., and achieve the effects of low preparation cost, excellent water resistance, and large water contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of polyurethane emulsion, comprising the following steps:

[0032] Polyurethane (PU) preparation specific steps:

[0033] First, 89.5 grams of polyether diol (N-210) was placed in a vacuum distillation device, and dehydrated by distillation and dehydration at 100 ° C for 1 hour; then 84 grams of toluene diisocyanate (TDI) were added together to the , in a four-necked flask with a reflux condenser, prepolymerized at 90°C for 2h; cooled to 80°C, added 12.5 grams of 2,2-dimethylolpropionic acid (DMPA), 1.5 grams of trimethylolpropane (TMP) and 27 grams of 1,4 cyclohexanedimethanol (CX) for chain extension reaction, constant temperature reaction for 1 hour; add 8 grams of epoxy resin (E-51), 4 grams of hydroxyethyl methacrylate (HEMA), keep at 70 ° C Capping reaction for 4 hours; cooling to 40°C, adding triethylamine (TEA) for neutralization for 10 minutes; adding 165 grams of acetone to adjust the viscosity during the whole reaction process, adding 40...

Embodiment 2

[0035] Preparation of FPUA:

[0036] 0.8 grams of sodium alkylphenol polyoxyethylene sulfate, 0.4 grams of alkyl alcohol polyoxyethylene ether, and 0.2 grams of sodium 1-propenyloxy-2-hydroxypropane sulfonate, 24 grams of butyl acrylate (BA), 16 grams Methyl methacrylate (MMA), 0.3 gram of methacrylic acid, 0.8 gram of acrylic acid, 0.8 gram of acrylamide and 24 gram of water are emulsified at high speed (1000r / min) to obtain a stable pre-emulsion; take 12 grams of PU emulsion and add 0.19 gram The sodium bicarbonate solution is heated to 80°C, then the pre-emulsion and the initiator solution are added dropwise simultaneously, the temperature is controlled at (80±2°C), and the pre-emulsion is dripped in 3.5 hours; slowly drop 1 gram of fluorine-containing acrylate monomer (G04) and the remaining initiator solution, control the temperature at (80±2°C), drop it in 0.5 hours, raise the temperature to 85°C, continue polymerization for 1h, cool to 40°C, adjust the pH to 8-9 with am...

Embodiment 3

[0040] Preparation of polyurethane-acrylate latex (PUA):

[0041]0.8 grams of sodium alkylphenol polyoxyethylene sulfate, 0.4 grams of alkyl alcohol polyoxyethylene ether, and 0.2 grams of sodium 1-propenyloxy-2-hydroxypropane sulfonate, 24 grams of butyl acrylate (BA), 16 grams Methyl methacrylate (MMA), 0.3 gram of methacrylate, 0.8 gram of acrylic acid, 0.8 gram of acrylamide and 24 gram of water were emulsified at high speed (1000r / min) to obtain a stable pre-emulsion; take 12 grams of PU emulsion, add 0.19 gram of sodium bicarbonate solution is heated to 80°C, then synchronously drop the pre-emulsion and initiator solution, control the temperature at (80±2°C), drop the pre-emulsion in 3.5 hours, raise the temperature to 85°C, continue to polymerize for 1h, cool to 40°C, adjust the pH to 8-9 with ammonia water and discharge.

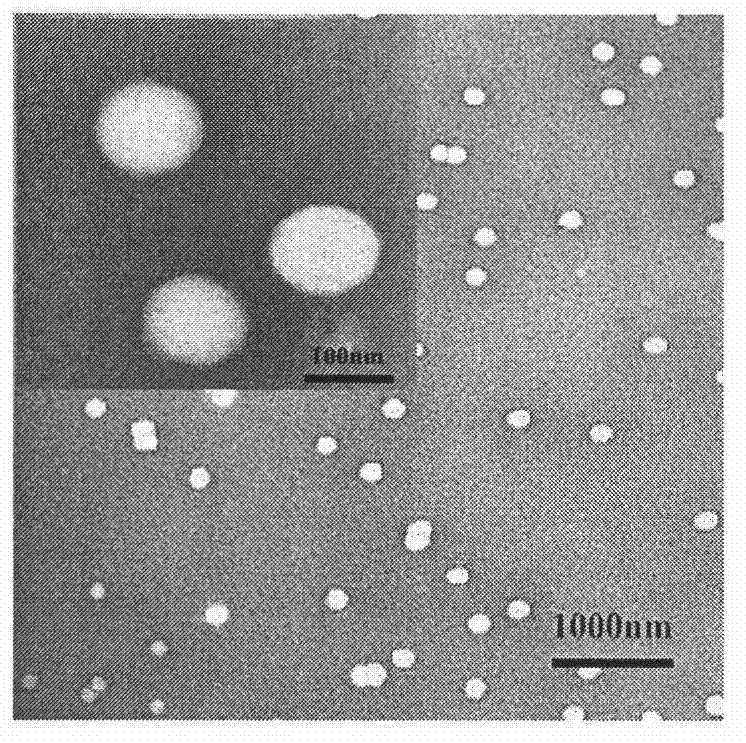

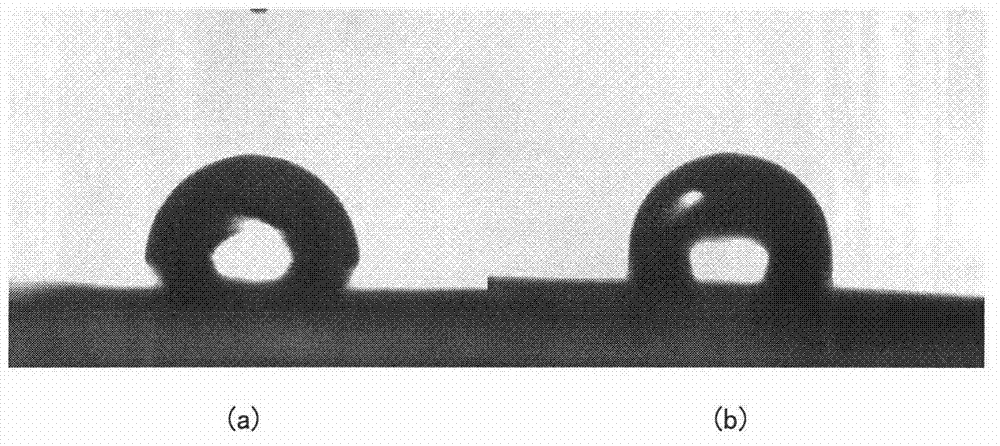

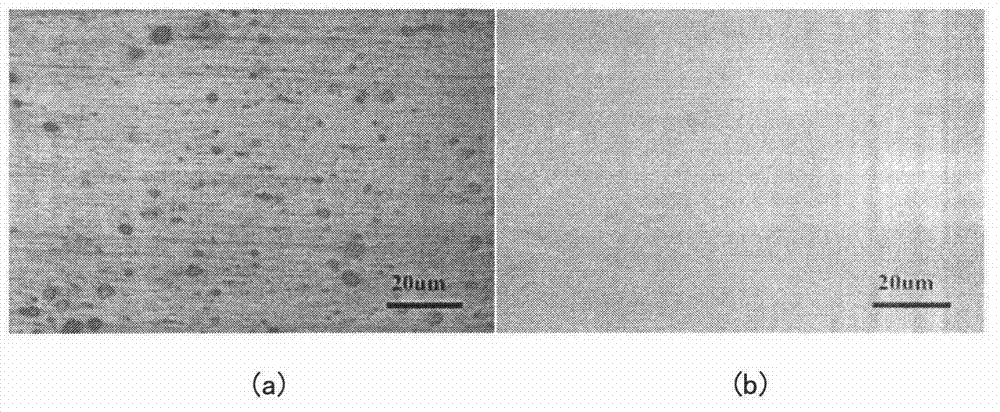

[0042] FPUA and PUA latex were respectively filmed on glass slides, and the water contact angle was measured. The results are as follows: figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com