Organic/inorganic hybrid hydrophilic modified hollow fiber polymer film and preparation method thereof

A fiber polymer, hydrophilic modification technology, applied in ultra/microfiltration hollow fiber membrane, hydrophilic modification of hollow fiber membrane, organic/inorganic hybrid hydrophilic modified hollow fiber polymer membrane and its preparation field , can solve the problems of high cost and complex composition, and achieve the effect of ultra-low transmembrane pressure, ultra-high rejection rate, and enhanced underwater oleophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

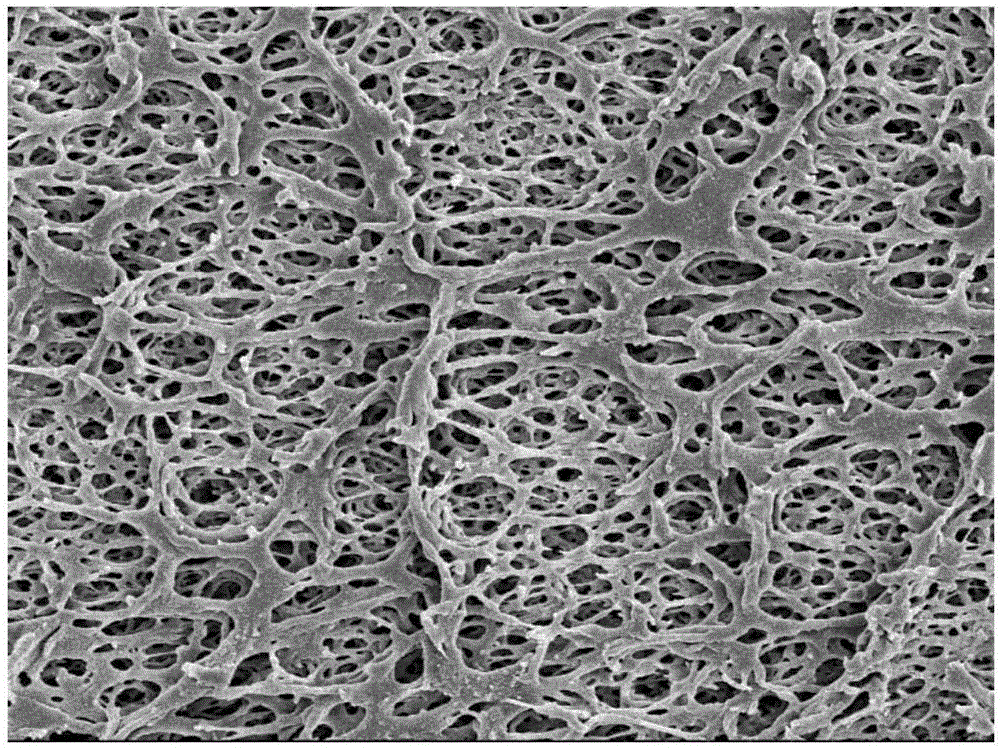

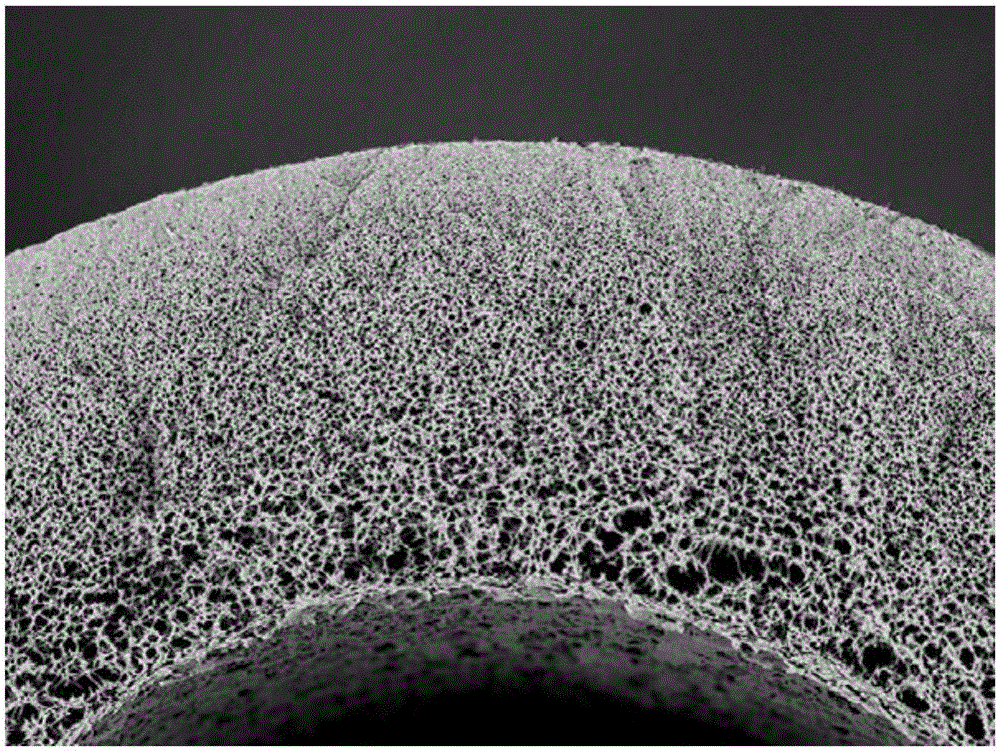

[0049] A polysulfone hollow fiber gradient membrane with an average pore size of 0.9-1.2 μm, a porosity of 60%, an inner diameter of 0.4 μm, and an outer diameter of 0.6 μm was used as the hollow fiber base membrane (purchased from Nanjing Jialejing Membrane Technology Co., Ltd., model PS640);

[0050] Concrete preparation steps are as follows:

[0051] (1) Tetraethyl orthosilicate TEOS and silane coupling agent Si(R 1 ) n (R 2 ) m (where R 1 for-OCH 2 CH 3 , R 2 for -CH 2 CH 2 CH 2 -(OCH 2 CH 2 ) t -OCH 2 CH 2 OH, and n is 3, m is 1, t is 50, purchased from Yiwu Zhongying Printing and Dyeing Auxiliary Co., Ltd., the model is SC3-EO50) added to absolute ethanol for mixing, stirred at room temperature until a clear state, Obtain a modified solution; wherein, in the modified solution, the total mass percent concentration of tetraethyl orthosilicate TEOS and the silane coupling agent is 10 wt%, and the mass ratio of TEOS to the silane coupling agent is 10:1;

[00...

Embodiment 2

[0057] A polyvinylidene fluoride hollow fiber gradient membrane with an average pore size of 0.5-0.8 μm, a porosity of 40%, an inner diameter of 0.3 μm, and an outer diameter of 1.0 μm was used as the hollow fiber base membrane (purchased from Nanjing Jialejing Membrane Technology Co., Ltd., model PVDF1030 );

[0058] The specific preparation method is as follows:

[0059] (1) Tetraethyl orthosilicate TEOS and silane coupling agent Si(R 1 ) n (R 2 ) m (where R 1 for-OCH 2 CH 3 , R 2 for -CH 2 CH 2 CH 2 -(OCH 2 CH 2 ) t -OCH 2 CH 2 OH, and n is 2, m is 2, t is 150, purchased from Yiwu Zhongying Printing and Dyeing Auxiliary Co., Ltd., the model is SC2-EO150) mixed with absolute ethanol, stirred at room temperature until it appears clear , to obtain a modified liquid, wherein, in the modified liquid, the total mass percentage concentration of ethyl orthosilicate TEOS and the silane coupling agent is 20wt%, and the mass ratio of TEOS to the silane coupling agent i...

Embodiment 3

[0065] A polyethersulfone hollow fiber gradient membrane with an average pore size of 0.8-1.0 μm, a porosity of 50%, an inner diameter of 0.6 μm, and an outer diameter of 0.9 μm was used as the polymer base membrane (purchased from Nanjing Jialejing Membrane Technology Co., Ltd., model PES960) ;

[0066] (1) butyl orthosilicate and silane coupling agent Si(R1 ) n (R 2 ) m (where R 1 for-OCH 3 , R 2 for -CH 2 CH 2 CH 2 -(OCH 2 CH 2 ) t -OCH 2 CH 2 OH, and n is 3, m is 1, t is 200, purchased from Yiwu Zhongying Printing and Dyeing Auxiliary Co., Ltd., the model is SC3-EO200) mixed with absolute ethanol, stirred at room temperature until it appears clear , to obtain the modified solution; wherein, in the modified solution, the total mass percentage concentration of butyl orthosilicate and silane coupling agent is 40wt%, and the mass ratio of butyl orthosilicate and silane coupling agent is 3:1 ;

[0067] (2) The catalyst aqueous ammonia is dissolved in deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com