ABC dry powder extinguishing agent

A technology of dry powder fire extinguishing agent and cross-linking catalyst, which is applied in the direction of fire prevention equipment, etc., which can solve the problems of water absorption of dry powder fire extinguishing agent, low moisture absorption rate, and reduced fire extinguishing ability, so as to improve the dispersion and film forming effect and the film forming temperature. Low, evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

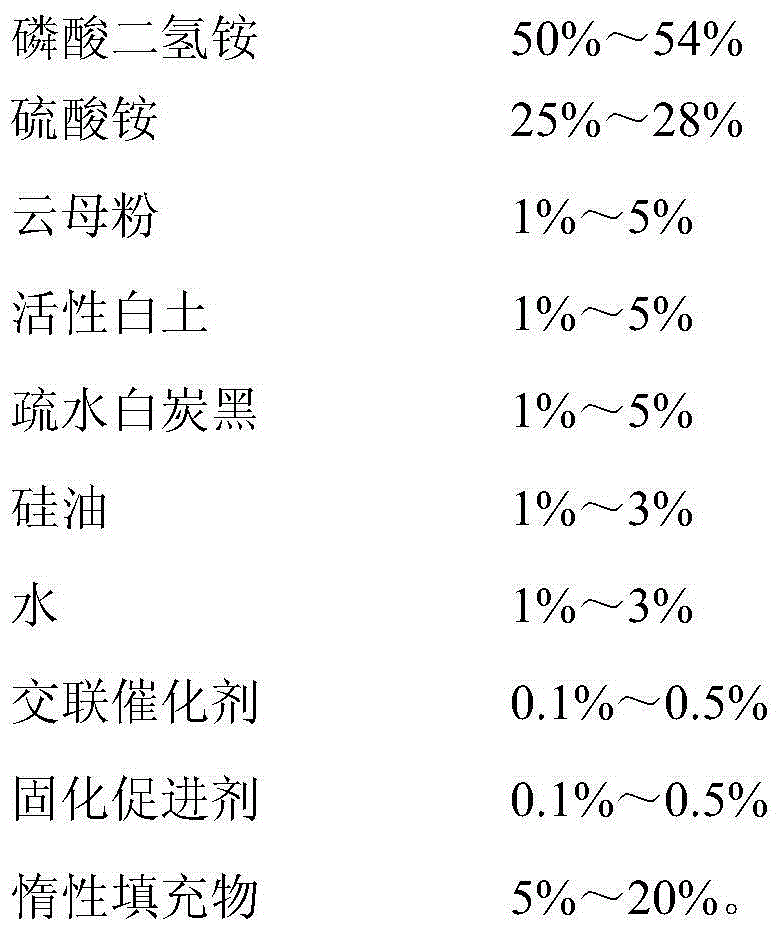

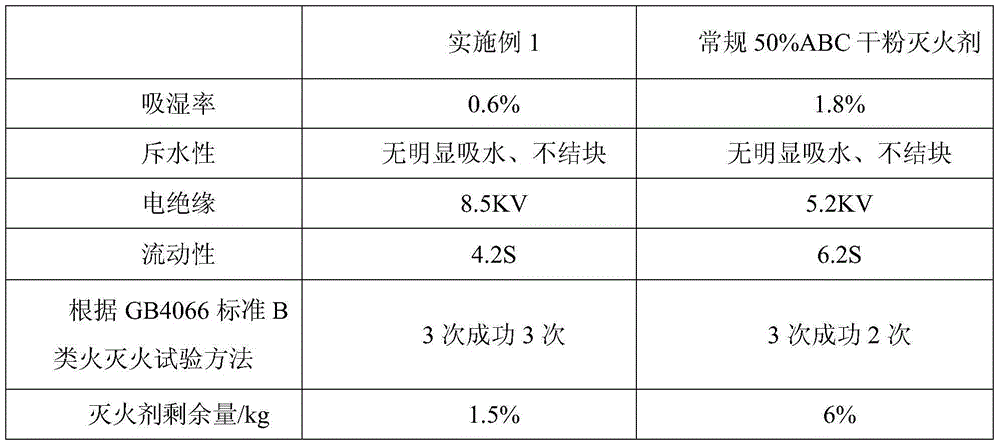

[0022] To prepare 1000kg of ABC dry powder fire extinguishing agent, weigh 500kg of ammonium dihydrogen phosphate, 250kg of ammonium sulfate, 20kg of mica powder, 20kg of activated clay, 20kg of hydrophobic white carbon black, 15kg of silicone oil, 20kg of water, 1.5kg of dibutyltin dilaurate, vinyl triethyl Oxysilane 2kg, talcum powder 151.5kg; (i.e. ammonium dihydrogen phosphate 50%, ammonium sulfate 25%, mica powder 2%, activated clay 2%, hydrophobic white carbon black 2%, silicone oil 1.5%, water 2%, two Dibutyltin Laurate 0.15%, Vinyl Triethoxysilane 0.2%, Talc 15.15%)

[0023] (1) Pre-siliconization of main raw materials: Mix 5kg of silicone oil with 500kg of ammonium dihydrogen phosphate and 250kg of ammonium sulfate;

[0024] (2) Crushing of main raw materials: the pre-silicified ammonium dihydrogen phosphate and ammonium sulfate are respectively pulverized by an ultrafine pulverizer, so that the "particle size distribution" of the pulverized ammonium dihydrogen phosph...

Embodiment 2

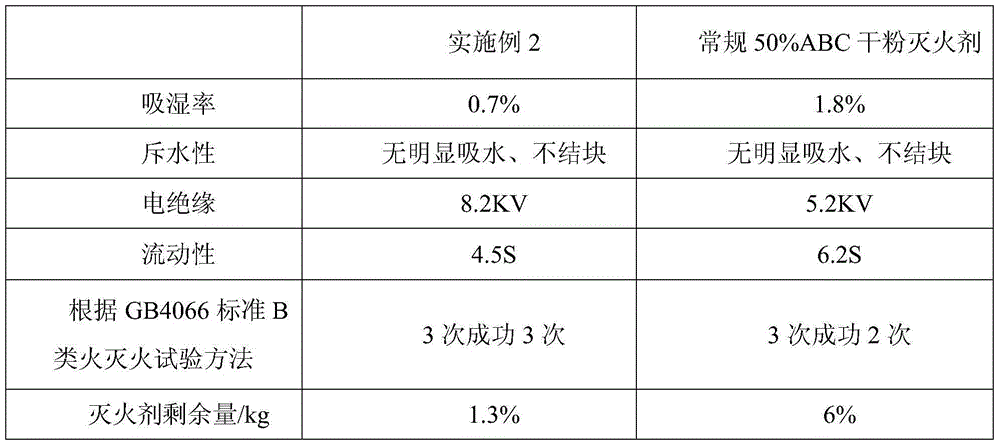

[0034] To prepare 1000kg of ABC dry powder fire extinguishing agent, weigh 500kg of ammonium dihydrogen phosphate, 260kg of ammonium sulfate, 30kg of mica powder, 30kg of activated clay, 20kg of hydrophobic white carbon black, 15kg of silicone oil, 20kg of water, 1.5kg of stannous octoate, and 2kg of vinyl trichlorosilane , talcum powder 121.5kg; (i.e. ammonium dihydrogen phosphate 50%, ammonium sulfate 26%, mica powder 3%, activated clay 3%, hydrophobic white carbon black 2%, silicone oil 1.5%, water 2%, stannous octoate 0.15% , vinyl trichlorosilane 0.2%, quartz sand 12.15%)

[0035] (1) Pre-siliconization of main raw materials: Mix 5kg of silicone oil with 500kg of ammonium dihydrogen phosphate and 260kg of ammonium sulfate;

[0036] (2) Crushing of main raw materials: the pre-silicified ammonium dihydrogen phosphate and ammonium sulfate are respectively pulverized by an ultrafine pulverizer, so that the "particle size distribution" of the pulverized ammonium dihydrogen pho...

Embodiment 3

[0045] Prepare 1000kg of ABC dry powder fire extinguishing agent, take by weighing 500kg of ammonium dihydrogen phosphate, 280kg of ammonium sulfate, 20kg of mica powder, 30kg of activated clay, 20kg of hydrophobic white carbon black, 20kg of silicone oil, 20kg of water, 3kg of stannous octoate, 3kg of vinyl trichlorosilane, Talc powder 104kg; (i.e. ammonium dihydrogen phosphate 50%, ammonium sulfate 28%, mica powder 2%, activated clay 3%, hydrophobic white carbon black 2%, silicone oil 2%, water 2%, dibutyltin diacetate 0.3%, Vinyl trichlorosilane 0.3%, Fluorite powder 10.4%)

[0046] (1) Pre-siliconization of main raw materials: Mix 8kg of silicone oil with 500kg of ammonium dihydrogen phosphate and 280kg of ammonium sulfate;

[0047](2) Crushing of main raw materials: the pre-silicified ammonium dihydrogen phosphate and ammonium sulfate are respectively pulverized by an ultrafine pulverizer, so that the "particle size distribution" of the pulverized ammonium dihydrogen phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com