Non-ionic ammonium hydrogen fluoride etching solution with low surface tension

A low surface tension, acidic ammonium fluoride technology, applied in the direction of surface etching compositions, chemical instruments and methods, etc., can solve the problems of weak permeability, high production cost, inability to adjust the surface tension of etching solution, etc., and achieve low surface tension Tension, increased permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

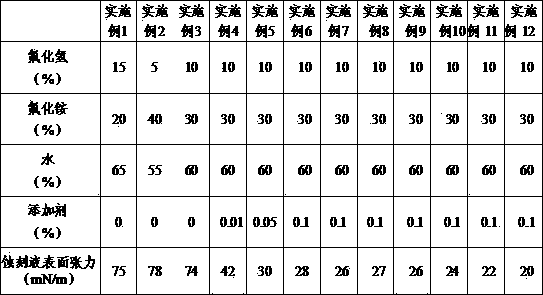

Examples

Embodiment 7

[0023] In Example 7, the additives are octylamine and polyglyceryl perfluorohexylsulfonate, the mass of octylamine in the additive accounts for 30% of the total amount of the additive, and the minimum etching pore size is 5 μm;

Embodiment 8

[0024] In Example 8, the additives are octylamine and polyglyceryl perfluorohexyl sulfonate, the mass of octylamine in the additive accounts for 40% of the total amount of the additive, and the minimum etching pore size is 5 μm;

Embodiment 9

[0025] In Example 9, the additives are octylamine and polyglyceryl perfluorohexyl sulfonate, the mass of octylamine in the additive accounts for 35% of the total amount of the additive, and the minimum etching pore size is 5 μm;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com