Preparation method of graphene composite foam for oil-water separation

A graphene composite and oil-water separation technology, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as performance degradation, structural damage, and secondary pollution of water bodies, and achieve improved flexibility, low cost, and improved Effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Graphene oxide was prepared by the oxidation exfoliation method, and a graphene oxide solution with a concentration of 2 mg / mL was prepared and ultrasonically treated for 2 h, then the same mass of dopamine was added and its pH was adjusted to 8.5 with ammonia water, and then placed in a reaction kettle at 180 °C Reaction at high temperature for 12h;

[0039] After cooling to room temperature, the hydrogel was taken out and immersed in a chitosan acetic acid solution with a concentration of 8mg / mL for 12h, and then freeze-dried at -55°C and a vacuum of 10Pa for 15h to prepare chitosan / graphene syntactic foam;

[0040] Then immerse it in 10mM 1H, 1H, 2H, 1H-perfluorodecyl mercaptan methanol solution for 24h, and finally put it in a hot blast drying oven and dry it at 50°C for 16h to obtain fluorinated graphene composite foam .

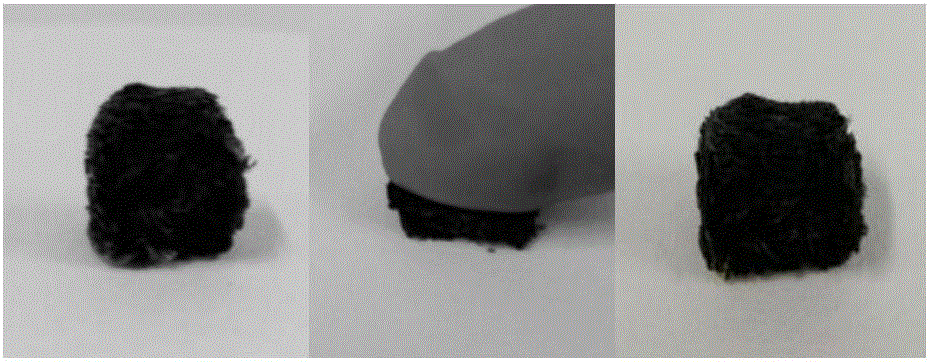

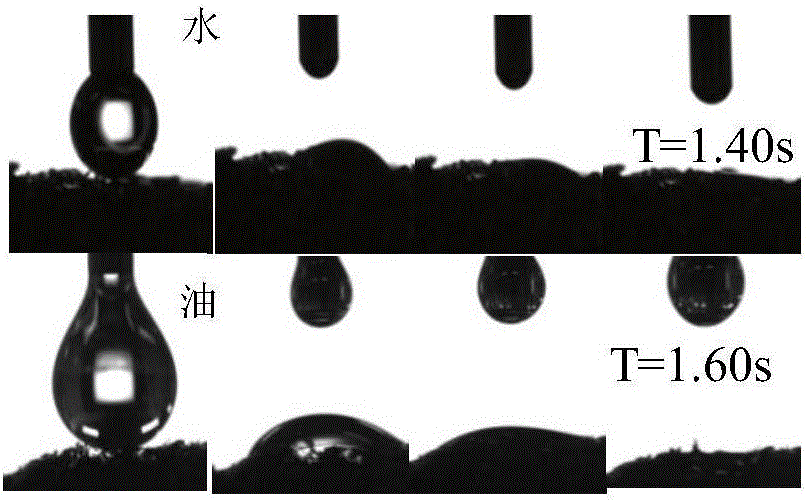

[0041] The prepared chitosan / graphene composite foam has good flexibility, and it can be compressed to the limit by external force, and the fo...

Embodiment 2

[0052] Graphene oxide was prepared by the oxidation exfoliation method, and the graphene oxide solution with a concentration of 2.5mg / mL was ultrasonically treated for 2h, then dopamine, which was half of the mass of graphene oxide, was added and the pH was adjusted to 8.5 with ammonia water, and then put into the reaction Reaction in the kettle at a high temperature of 160°C for 12 hours;

[0053] After cooling to room temperature, take it out and immerse it in a chitosan acetic acid solution with a concentration of 10mg / mL to react for 8h, then freeze-dry it at -40°C and a vacuum of 10Pa for 18h to prepare a chitosan / graphene composite foam;

[0054] Then immerse it in 10mM 1H, 1H, 2H, 1H-perfluorodecyl mercaptan methanol solution for 24h, and finally put it in a hot blast drying oven and dry it at 60°C for 12h to obtain fluorinated graphene composite foam .

[0055] Chitosan / graphene composite foam has good flexibility and self-cleaning effect. Both graphene composite foam...

Embodiment 3

[0057] Graphene oxide was prepared by the oxidation exfoliation method, and the graphene oxide solution with a concentration of 3mg / mL was ultrasonically treated for 2h, then dopamine twice the mass of graphene oxide was added and the pH was adjusted to 8.5 with ammonia water, and then put into the reactor React at a high temperature of 120°C for 15 hours;

[0058] After cooling to room temperature, take out and immerse in a chitosan acetic acid solution with a concentration of 12 mg / mL to react for 6 hours, then freeze-dry at -45°C and a vacuum of 10 Pa for 16 hours to prepare a chitosan / graphene composite foam;

[0059] Then it was immersed in 10mM 1H, 1H, 2H, 1H-perfluorodecyl mercaptan ethanol solution for 24h, and finally placed in a hot blast drying oven at 55°C for 15h to obtain a fluorinated graphene composite. Foam.

[0060] Both chitosan / graphene composite foams have good flexibility and self-cleaning effect. Both graphene composite foams can achieve efficient and s...

PUM

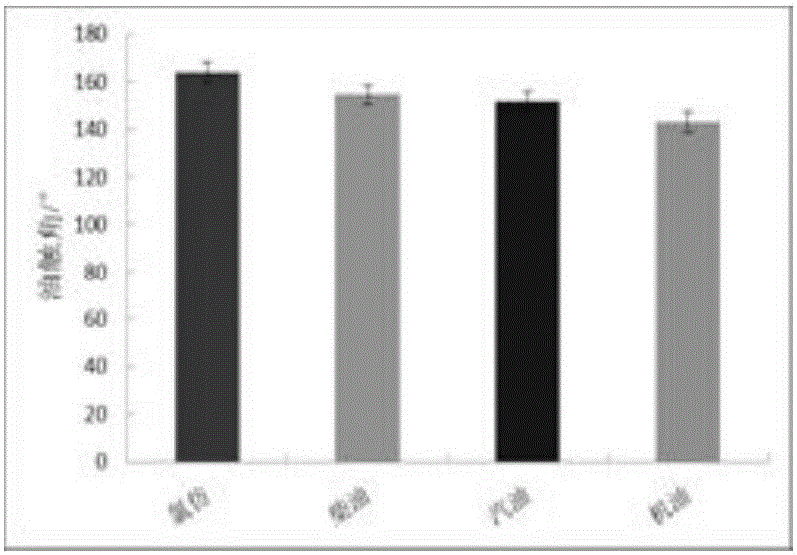

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com