Nanopowder hydrophobicity and lipophobicity modification method

A nano-powder, hydrophobic and oleophobic technology, applied in the direction of coating, etc., can solve the problem of complex solution configuration, and achieve the effect of simple operation steps, stable performance and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

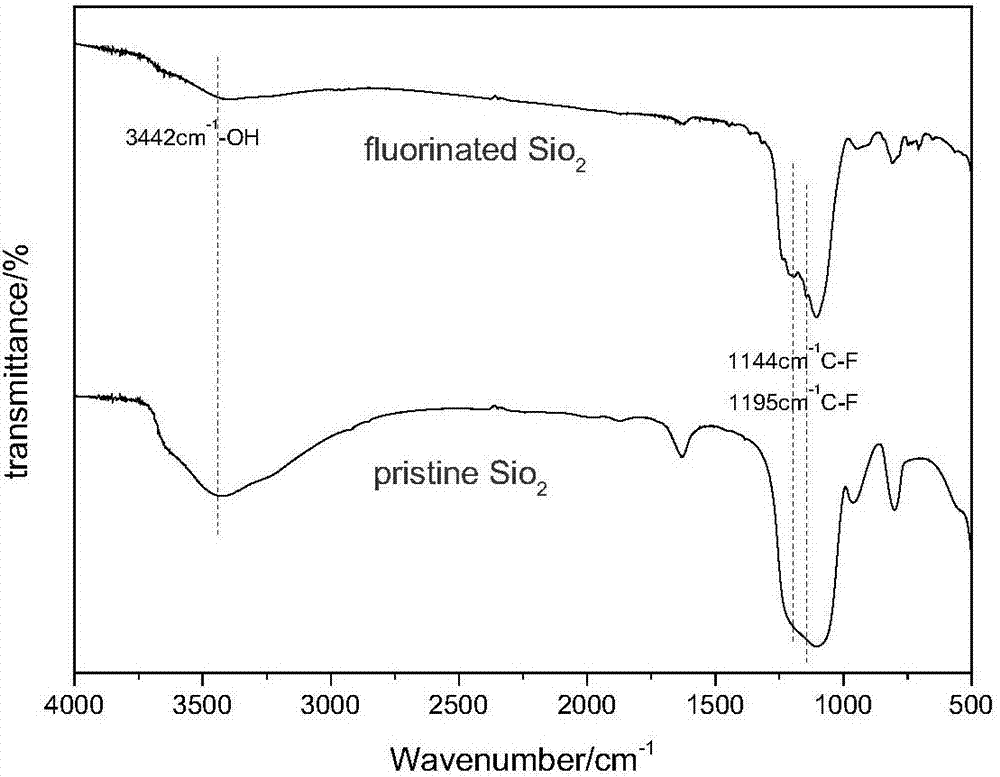

[0028] (1) Mix silica nano-powder with a particle size of 10nm-100nm and cyclohexane, and treat it with an ultrasonic disperser for 10 minutes to obtain a uniformly dispersed suspension.

[0029] (2) Add perfluorooctyltrimethoxysilane dropwise to the suspension obtained in step (1) for impregnation treatment, and stir at 500 rpm for 12 hours. Wherein the mass percentage of each substance is: the amount of nano silicon dioxide is 1.0%, the amount of cyclohexane is 98.0%, and the mass fraction of perfluorooctyltrimethoxysilane is 1%.

[0030] (3) The impregnated suspension is spray-dried, the air inlet temperature of the spray-drying is controlled at 120-150°C, and the outlet temperature is at 60-80°C. Fluorinated silica is obtained.

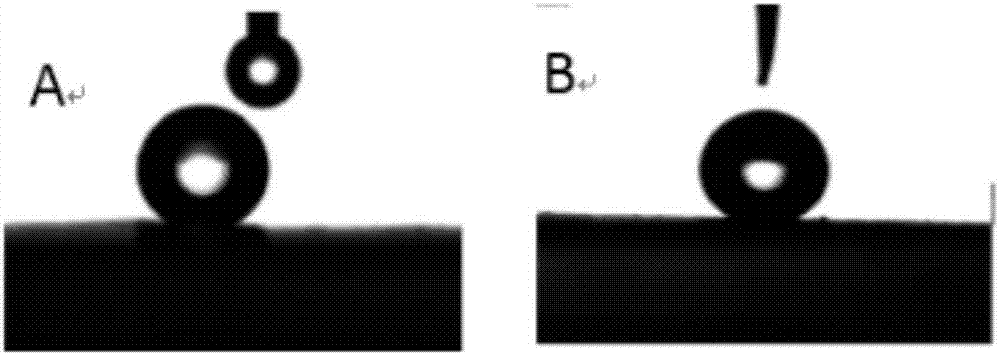

[0031] Modification results: The contact angle was measured by DropMeterA-100P contact angle measuring instrument. The water contact angle of fluorinated silica is about 150°, and the oil contact angle is about 162°.

Embodiment 2

[0033] (1) Mix silica nanopowder with a particle size of 10nm-100nm and cyclohexane, and treat it with an ultrasonic disperser for 30 minutes to obtain a uniformly dispersed suspension.

[0034] (2) Add perfluorooctyltrimethoxysilane dropwise to the suspension obtained in step (1) for impregnation treatment, and stir at 600 rpm for 24 hours. Wherein the mass percentage of each substance is: the amount of nano silicon dioxide is 2.0%, the amount of cyclohexane is 96.0%, and the mass fraction of perfluorooctyltrimethoxysilane is 2%.

[0035] (3) The impregnated suspension is spray-dried, the air inlet temperature of the spray-drying is controlled at 120-150°C, and the outlet temperature is at 60-80°C. Fluorinated silica is obtained.

[0036] Modification results: The contact angle was measured by DropMeterA-100P contact angle measuring instrument. The water contact angle of fluorinated silica is about 152°, and the oil contact angle is about 165°.

Embodiment 3

[0038] (1) Mix titanium dioxide nanopowder with a particle size of 10nm-100nm and cyclohexane, and treat it with an ultrasonic disperser for 10 minutes to obtain a uniformly dispersed suspension.

[0039] (2) Add perfluorooctyltrimethoxysilane dropwise to the suspension obtained in step (1) for impregnation treatment, and stir at 1000 rpm for 12 hours. Wherein the mass percentage of each substance is: the amount of nano-titanium dioxide is 1.0%, the amount of cyclohexane is 98.0%, and the mass fraction of perfluorooctyltrimethoxysilane is 1%.

[0040] (3) The impregnated suspension is spray-dried, the air inlet temperature of the spray-drying is controlled at 120-150°C, and the outlet temperature is at 60-80°C. Fluorinated silica is obtained.

[0041] Modification results: The contact angle was measured by DropMeterA-100P contact angle measuring instrument. The water contact angle of fluorinated silicon dioxide was about 152°, and the oil contact angle was about 153°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Oil contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com