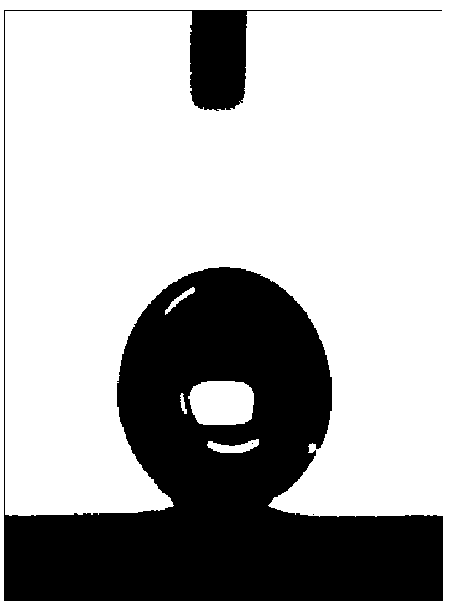

Reparation method for zinc super-hydrophobic surface

A super-hydrophobic surface and zinc flake technology, which is applied in the coating process of metal materials, etc., can solve the problems of harsh preparation conditions for super-hydrophobic surfaces, obstacles to the application of super-hydrophobic surfaces, complex preparation processes, etc., and achieve simple equipment, wide application range, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

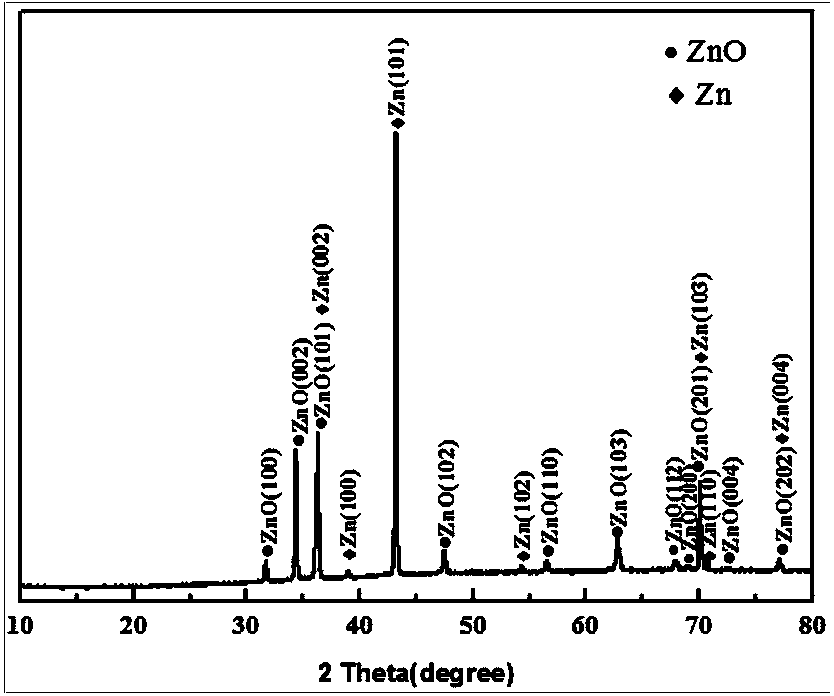

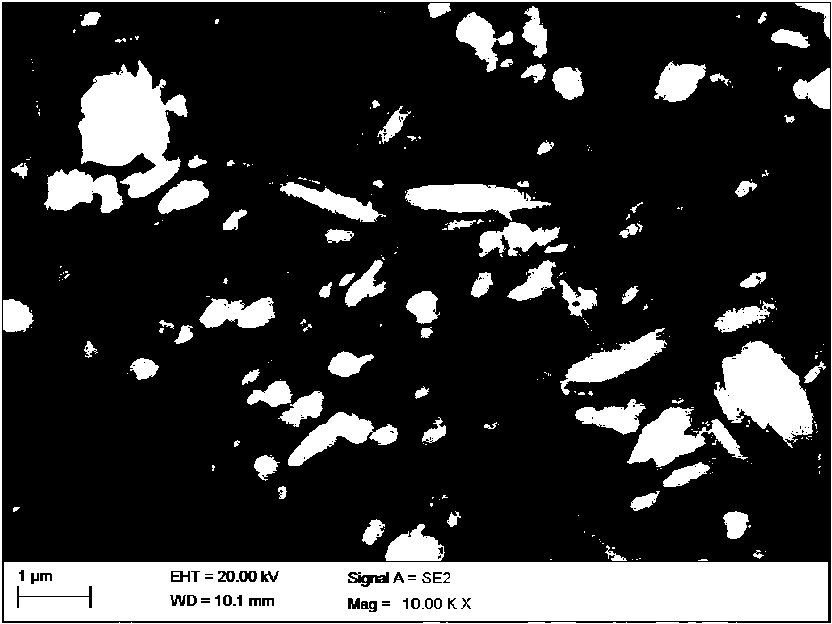

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments. The following descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention to other forms. Changes to equivalent embodiments with equivalent changes. Any simple modifications or equivalent changes made to the above embodiments according to the technical essence of the present invention without departing from the solution content of the present invention fall within the protection scope of the present invention.

[0026] A method for preparing a zinc superhydrophobic surface, specifically completed by the following steps:

[0027] (1) configure hydrochloric acid aqueous solution, concentration is 1.5mol / L;

[0028] (2) Take a zinc sheet (Shanghai Ailiai Metal Material Co., Ltd.) with a thickness of about 2mm and a purity of 99.99% as the substrate, and polish the surface of the zinc sheet with metallographic sandpaper to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com