Method for preparing ultra-oleophobic surface underwater

An underwater super-oleophobic and oleophobic technology is applied in the field of surface modification of solid materials, which can solve the problems of high consumption cost and complex process, and achieve the effects of no environmental pollution, simple equipment and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Adding chitosan with a molecular weight of 300kg / mol and a degree of deacetylation of 90% to 2v% acetic acid aqueous solution and stirring to obtain a 2wt% chitosan acetic acid solution, the solution is cast on a clean glass sheet and dried to obtain a smooth film . The surface of the film is smooth without rough structure, the contact angle of the surface with water in air is 15°, and the contact angle with chloroform under water is 125°.

[0024] Its surface morphology is shown in the appendix figure 1 .

Embodiment 2

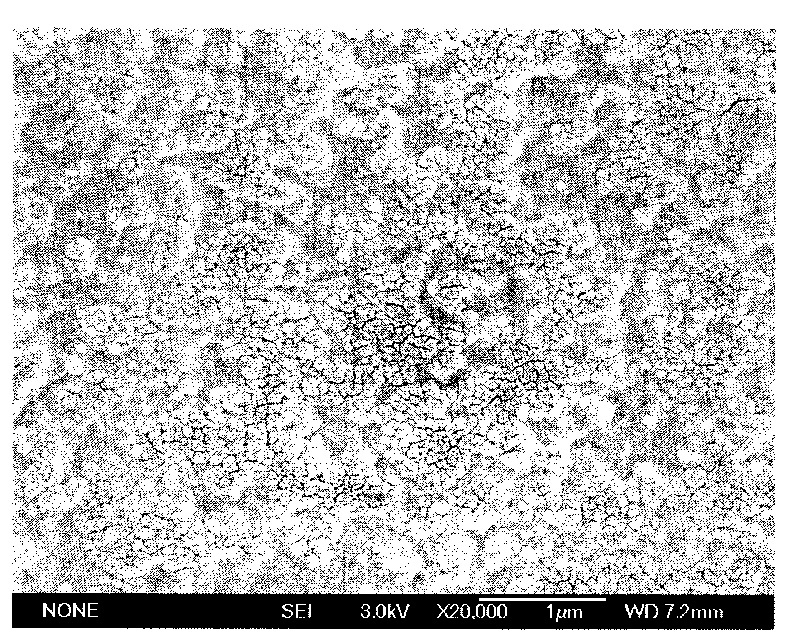

[0026] Molecular weight is 300kg / mol, the chitosan that deacetylation degree is 70% is added in the acetic acid aqueous solution of 2v% and stirs and obtains the chitosan acetic acid solution of 2wt%, this solution casts a film on the clean glass sheet, afterwards in 2mol / Soak in L of sodium hydroxide solution for 2 minutes, wash with water three times, and dry at room temperature to obtain a rough surface. The size of the surface rough structure is 0.01-0.1 micron, the contact angle of the surface with water in air is 10°, and the contact angle with dichloroethane under water is 158°.

[0027] Its surface morphology is shown in the appendix figure 2 .

Embodiment 3

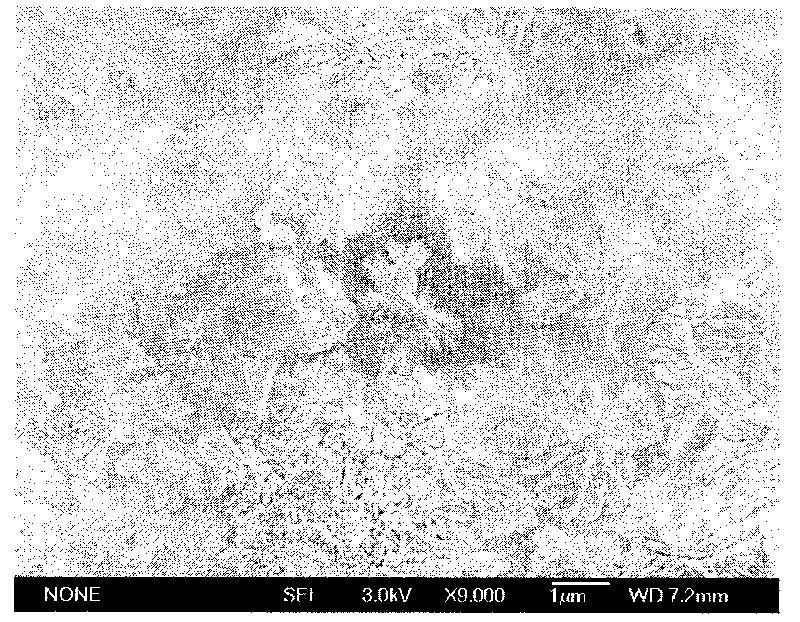

[0029] The molecular weight is 200kg / mol, the chitosan that the degree of deacetylation is 95% is added in the acetic acid aqueous solution of 1v% and stirs to obtain the chitosan acetic acid solution of 3wt%, this solution casts a film on the clean glass sheet, with 1mol / L soak in sodium hydroxide solution for 5 minutes, then wash with water three times, and dry at room temperature to obtain a rough surface. The contact angle with chloroform is 150°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com