Photocatalytic oil-water separation net film, preparation method and application thereof

An oil-water separation mesh membrane and photocatalysis technology, which is applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problem of not being able to make better use of sunlight and other problems, so as to improve the carrier transmission efficiency and improve the transmission efficiency. , the effect of convenient follow-up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation of a photocatalytic oil-water separation omentum, comprising the steps of:

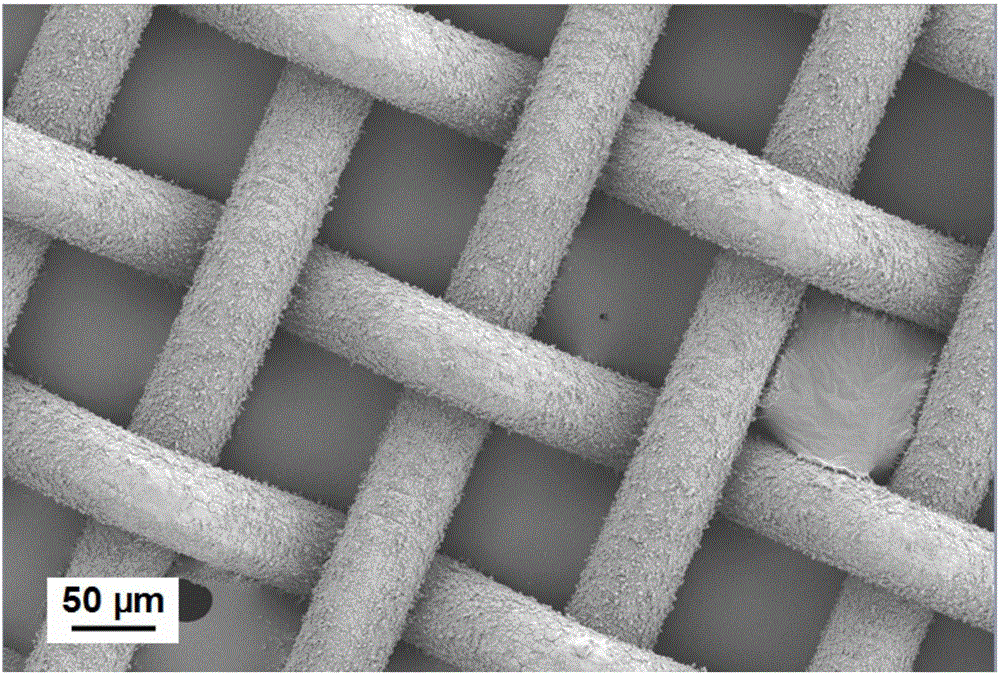

[0042] 1) Clean the 200-mesh copper mesh with 0.1mol / L dilute hydrochloric acid, absolute ethanol and deionized water for 15 minutes, and dry it with nitrogen for later use;

[0043] 2) With 0.1mol / L sodium tungstate solution as the electrolyte, the cleaned 3×4cm 2 The copper mesh is used as the anode, with a size of 3×4cm 2 The titanium plate is used as the cathode, and the anode and the cathode are respectively connected to the positive and negative poles of the power supply. The anodic oxidation method is used to electrolyze for 5 minutes at a constant voltage of 4V, and the electrolysis temperature is 25°C;

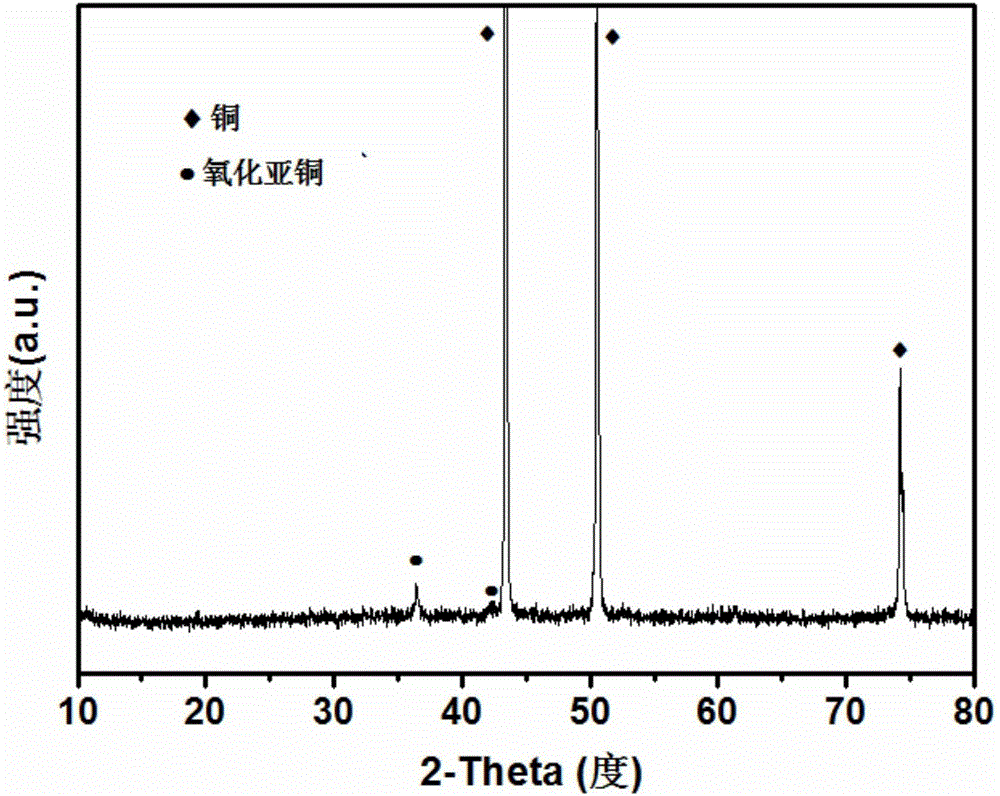

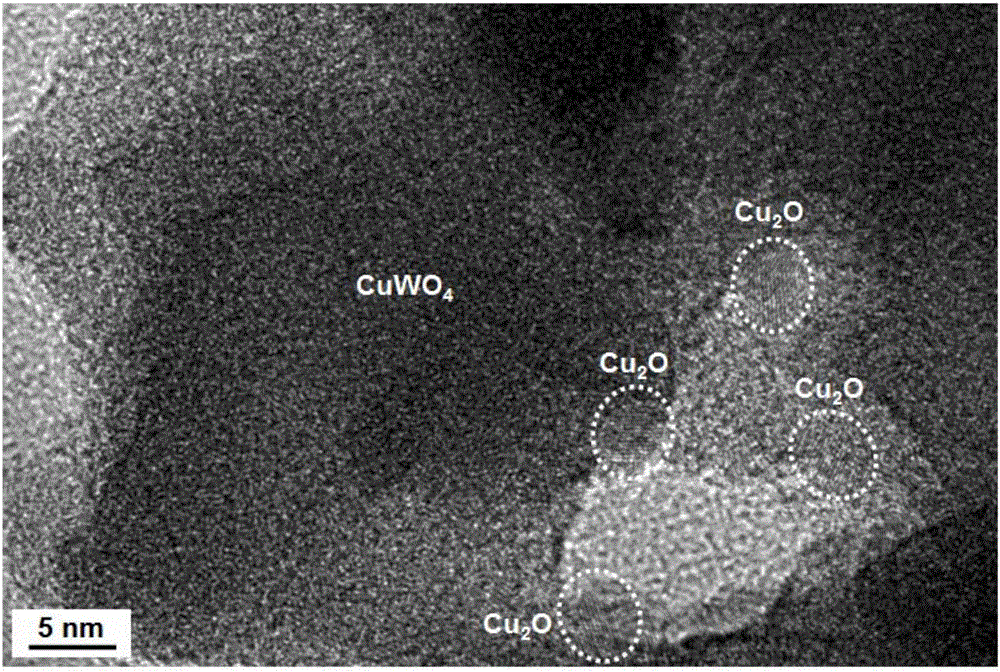

[0044] 3) After the electrolysis is completed, wash the anode with deionized water and dry it in a blast drying oven at a constant temperature of 50°C for 0.5h to obtain a copper mesh covered with a cuprous oxide / copper tungstate composite film layer.

[0045] The oil-w...

Embodiment 2

[0054] A preparation of a photocatalytic oil-water separation omentum, comprising the steps of:

[0055] 1) Clean the 300-mesh phosphorus copper mesh with 0.1mol / L dilute hydrochloric acid, absolute ethanol and deionized water for 10 minutes, and dry it with nitrogen for later use;

[0056] 2) With 0.005mol / L potassium tungstate solution as the electrolyte, the cleaned 3×4cm 2 The copper mesh is used as the anode, with a size of 3×4cm 2 The platinum sheet is used as the cathode, and the anode and the cathode are respectively connected to the positive pole and the negative pole of the power supply. The anodic oxidation method is used to electrolyze at a constant voltage of 20V for 20min, and the electrolysis temperature is 15°C;

[0057] 3) After the electrolysis is completed, wash the anode with deionized water and dry it in a blast drying oven at a constant temperature of 60°C for 1.0h to obtain a copper mesh covered with a cuprous oxide / copper tungstate composite film layer...

Embodiment 3

[0060] A preparation of a photocatalytic oil-water separation omentum, comprising the steps of:

[0061] 1) Clean the 400-mesh phosphorus copper mesh with 0.1mol / L dilute hydrochloric acid, absolute ethanol and deionized water for 12 minutes, and dry it with nitrogen for later use;

[0062] 2) With 0.01mol / L ammonium tungstate solution as the electrolyte, the cleaned 3×4cm 2 The copper mesh is used as the anode, with a size of 3×4cm 2 The graphite sheet is used as the cathode, so that the anode and the cathode are respectively connected to the positive and negative electrodes of the power supply. 2 The constant current electrolysis of 15min, the electrolysis temperature is 20 ℃;

[0063] 3) After electrolysis, wash the anode with deionized water and dry it in a blast drying oven at a constant temperature of 80°C for 0.6h to obtain a copper mesh covered with a cuprous oxide / copper tungstate composite film layer.

[0064] The water contact angle of the omentum prepared by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com