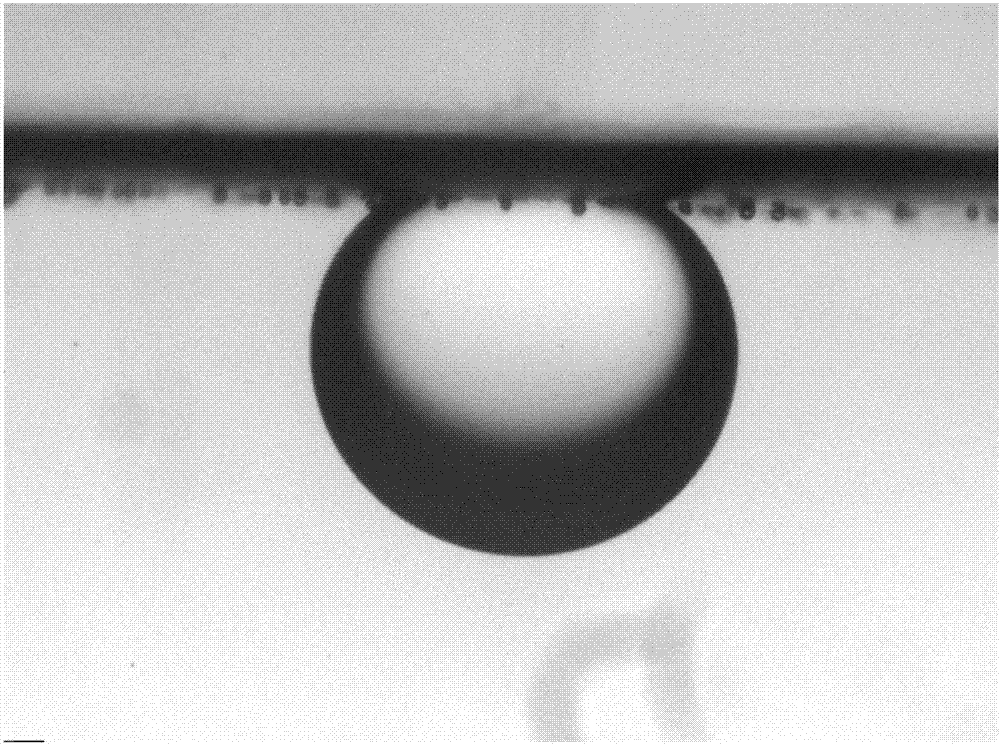

Preparation method of oil-water separation mesh film with super-hydrophilicity and super-lipophobicity

An oil-water separation mesh membrane, superoleophobic technology, applied in functional materials, chemical and chemical fields, can solve the problems of complex manufacturing process, difficult to remove oil, affecting separation efficiency, etc., achieve simple equipment and manufacturing process, fast oil-water separation speed, The effect of cheap and easily available raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

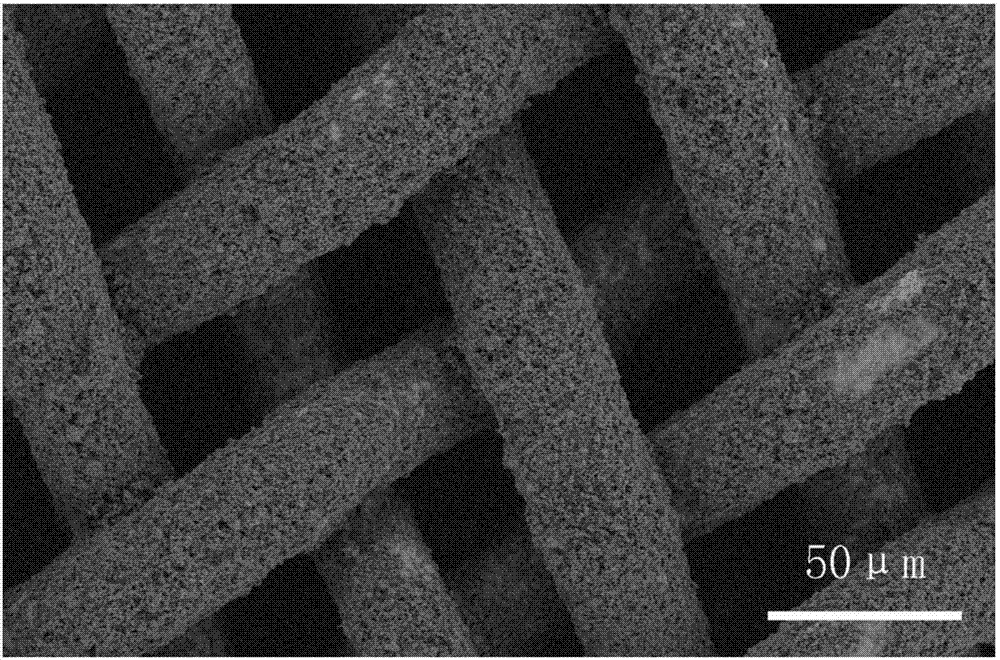

[0025] (1) Soak a 1000-mesh (15 μm pore size) stainless steel mesh (5 cm x 5 cm) in acetone, isopropanol and deionized water for 10 minutes, and dry at room temperature;

[0026] (2) At room temperature, add 1 g of titanium dioxide (particle size 8 nanometers) and 150 ml of tetrahydrofuran (133.4 g) into a 250 ml single-necked bottle, and obtain 134.4 g of a stable suspension solution by ultrasonication for 60 minutes;

[0027] (3) the suspension solution that step (2) is obtained utilizes the high-pressure gas of air compressor to evenly spray to the surface of (1) dried stainless steel net; The nozzle aperture of spray gun is 1.0mm, and the air compressor pressure that connects spray gun remains on 0.4MPa, the spraying distance is 16cm.

[0028] (4) Aging the stainless steel mesh sprayed with the suspension in step (3) at room temperature for 30 minutes, and finally sintering at 550°C for 150 minutes to obtain an oil-water separation mesh with superhydrophilic and superoleop...

Embodiment 2

[0034] (1) immerse an 800-mesh (19 micron aperture) copper grid (5 cm x 5 cm) in acetone, isopropanol and deionized water for 10 minutes, and then dry it at room temperature;

[0035] (2) At room temperature, add 1g zinc oxide (particle size 10nm), 0.5g silicon dioxide (particle size 15nm), 100ml tetrahydrofuran (88.9g) into a 250ml single-necked bottle, and obtain 90.4g stable suspension for 80 minutes. solution;

[0036] (3) the suspension solution that step (2) is obtained utilizes the high-pressure gas of air compressor to be evenly sprayed to the surface of (1) dried copper net; The nozzle aperture of spray gun is 1.0mm, and the air compressor pressure that connects spray gun remains on 0.4MPa, the spraying distance is 16cm.

[0037] (4) Aging the copper mesh sprayed with the suspension in step (3) at room temperature for 50 minutes, and finally sintering at 450°C for 180 minutes to obtain an oil-water separation mesh with superhydrophilic and superoleophobic properties,...

Embodiment 3

[0041] (1) Submerge a 400-mesh (37 micron aperture) iron grid (5 cm x 5 cm) in acetone, isopropanol and deionized water for 10 minutes, and then dry it at room temperature;

[0042] (2) At room temperature, add 1g of zinc oxide (particle size 20 nanometers), 0.5g calcium carbonate (particle size 16 nanometers), 0.5g silicon dioxide (particle size 21 nanometers), 150ml tetrahydrofuran (133.4g ), ultrasonic 120 minutes obtains 135.4g stable suspension solution;

[0043] (3) the suspension solution that step (2) is obtained utilizes the high-pressure gas of air compressor to evenly spray to the surface of (1) dried iron net; The nozzle aperture of spray gun is 1.0mm, and the air compressor pressure that connects spray gun remains on 0.4MPa, the spraying distance is 16cm.

[0044] (4) Aging the iron mesh sprayed with the suspension in step (3) for 70 minutes at room temperature, and finally sintering at 350°C for 240 minutes to obtain an oil-water separation mesh with superhydrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com