Separation net membrane with super-hydrophilicity/underwater super-lipophobicity as well as preparation method and application thereof

An oleophobic and super-hydrophilic technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of poor solvent resistance and low thermal stability, and achieve environmentally friendly, easy-to-clean, simple and easy-to-use processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

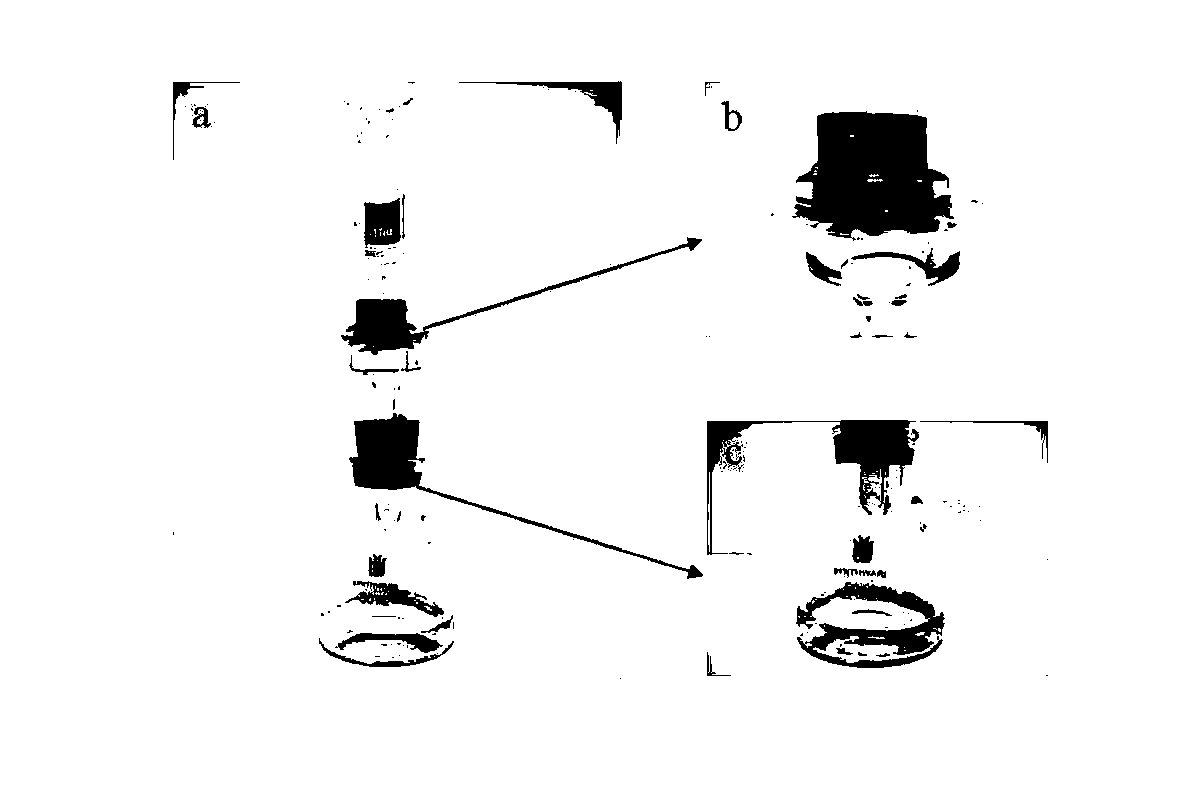

[0045] As a typical specific application example, the preparation method of the separation omentum of the present invention may comprise the following steps:

[0046] (1) Soak the metal mesh in deionized water and ultrasonically oscillate to remove impurities on the surface, then immerse it in absolute ethanol for ultrasonic oscillation cleaning, take it out, rinse it with deionized water, and dry it.

[0047] (2) Dissolve the inorganic base and the oxidizing agent in water with an electronic balance to prepare a homogeneous aqueous solution. The concentration of lye is 0.5-5 M, and the concentration of oxidant is 0.01-1.0 M.

[0048] (3) Soak the pre-washed and dried copper mesh in the solution for oxidation reaction, thereby forming nanowires covering the mesh on the surface of the metal mesh, and obtaining a separation mesh with underwater superoleophobic properties. After the reaction, the omentum was taken out, washed repeatedly with deionized water, and dried naturally ...

Embodiment 1

[0052] (1) Dip the 200-mesh copper grid into deionized water and ethanol for ultrasonic cleaning, then rinse with deionized water and dry naturally.

[0053] (2) At room temperature, add 100mL of water, 1g of sodium hydroxide and 1.92g of ammonium persulfate into a 150mL beaker, stir and mix evenly to prepare a uniform aqueous solution.

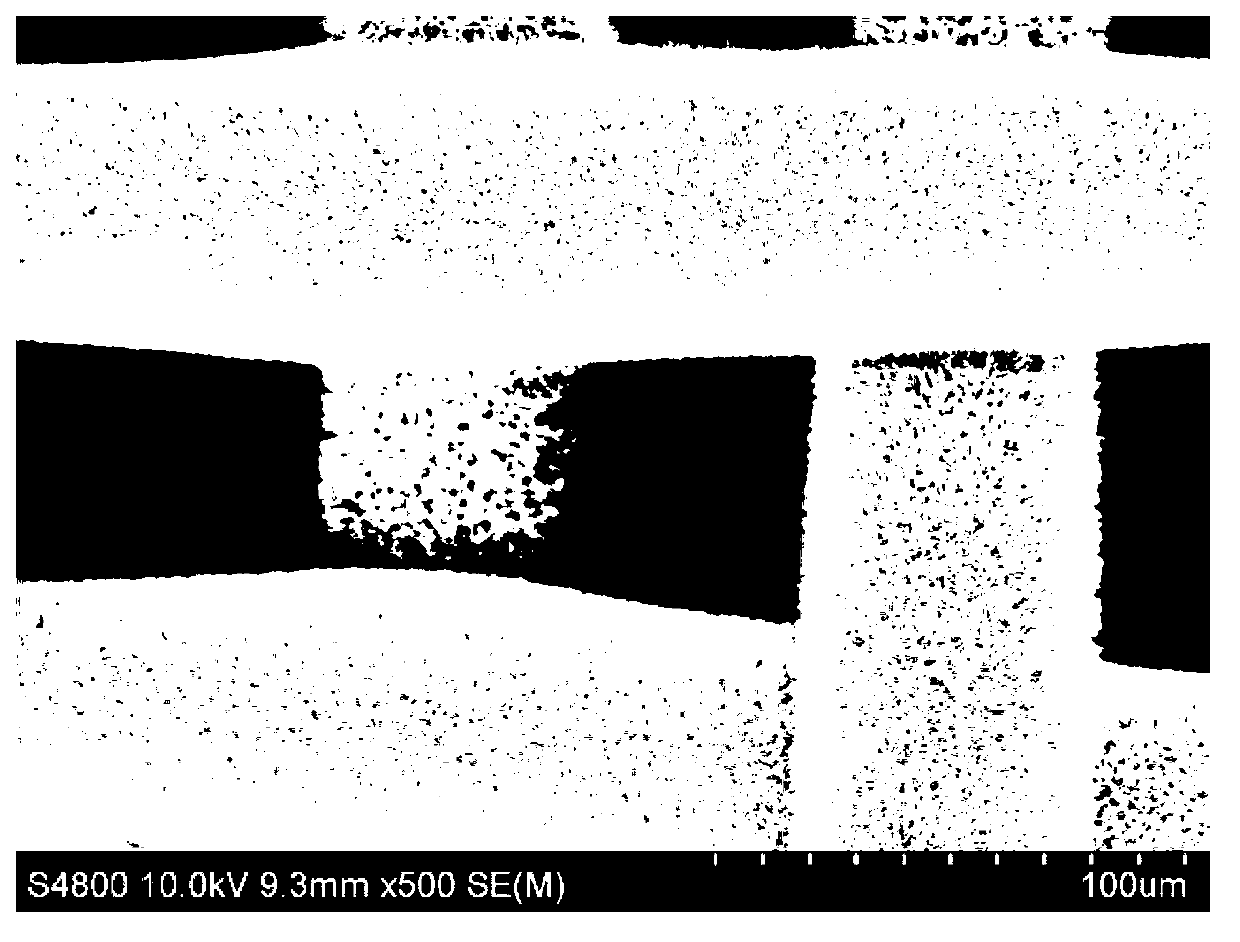

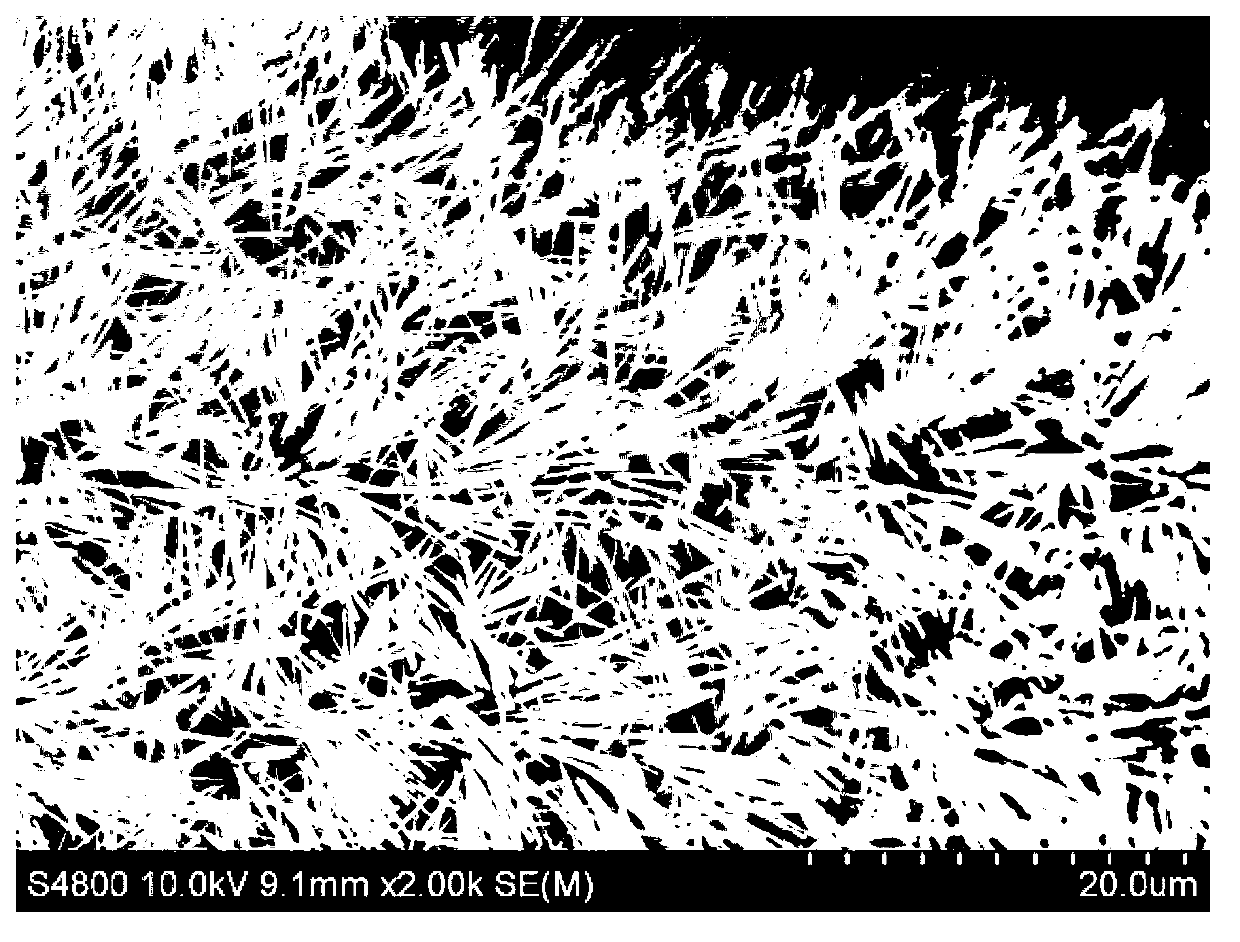

[0054] (3) Soak the pre-cleaned copper mesh in step (1) in the solution for oxidation reaction, the reaction time is 20 minutes, thereby forming copper hydroxide nanowires covering the metal mesh on the surface of the metal mesh, the length of the nanowire It is about 3-7μm. Take out the omentum after the reaction, wash it repeatedly with deionized water, and dry it naturally in the air. The nature of the separation omentum, the pore size of the omentum is about 55-60μm.

[0055] (4) measure the separation omentum that step (3) obtains with contact angle measuring instrument, the contact angle of this film surface to the water of 3 microlite...

Embodiment 2

[0058] (1) Dip the 300-mesh copper mesh into deionized water and ethanol for ultrasonic cleaning, then rinse with deionized water and dry naturally.

[0059] (2) At room temperature, add 100mL of water, 2 grams of sodium hydroxide and 2.96 grams of ammonium persulfate into a 150mL beaker, stir and mix evenly to prepare a uniform aqueous solution.

[0060] (3) Soak the pre-cleaned copper mesh in step (1) in the solution for oxidation reaction, the reaction time is 10 minutes, thereby forming copper hydroxide nanowires covering the metal mesh on the surface of the metal mesh, the length of the nanowire It is about 3-5μm. Take out the omentum after the reaction, wash it repeatedly with deionized water, and let it dry naturally in the air. The nature of the separation omentum, the omentum pore size is about 35-40μm.

[0061] (4) Measure the separated omentum that step (3) obtains with a contact angle measuring instrument, and the contact angle of the film surface to 3 microliters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com