Perfluoro alkyl phosphoester acrylic ester and preparation thereof

A technology of perfluoroalkyl phosphate acrylate and monohydroxy acrylate, which is applied in the field of UV-curable hydrophobic and oleophobic materials, which can solve the problems of difficult to obtain polymer films, no hydrophobic and oleophobic properties, and limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

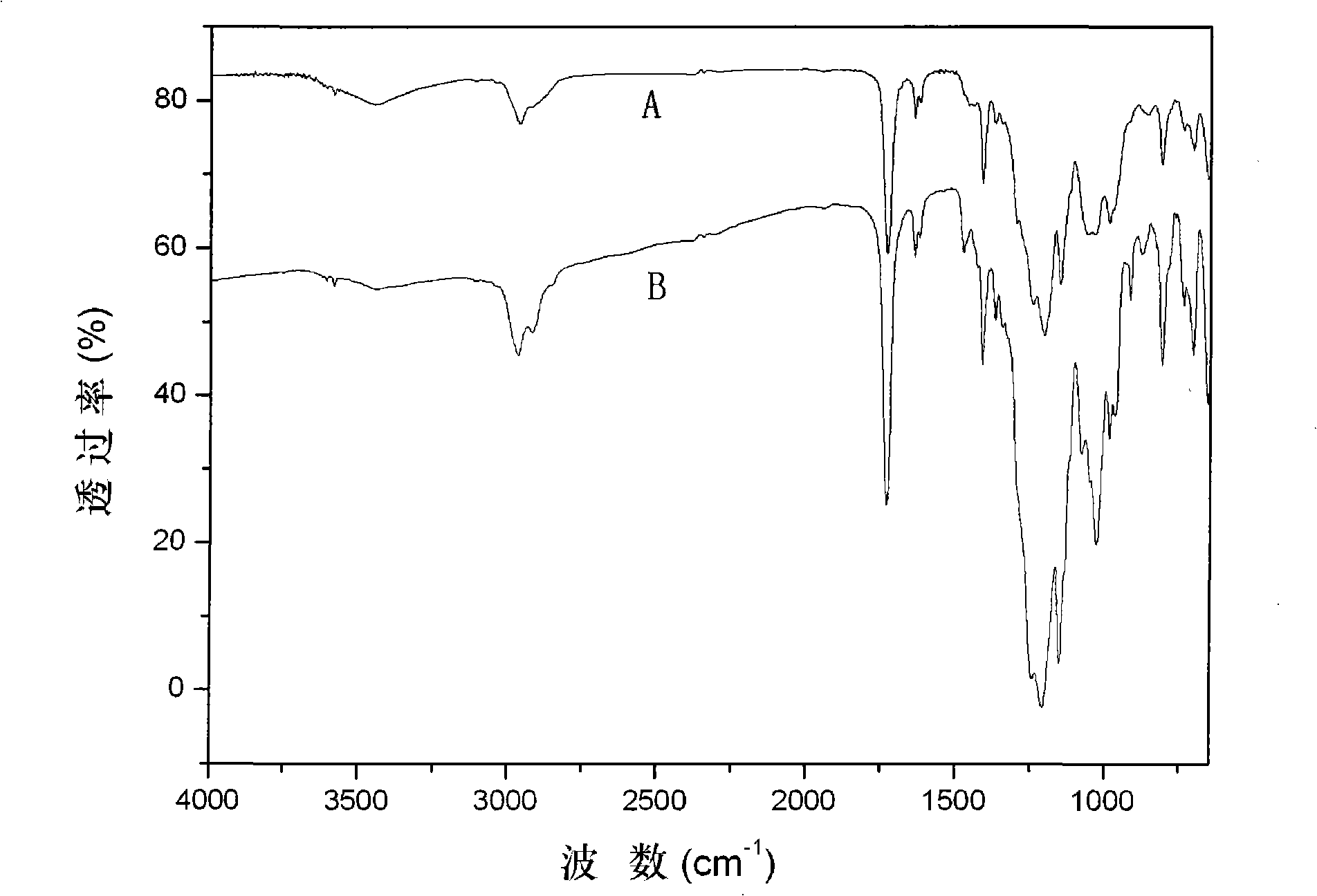

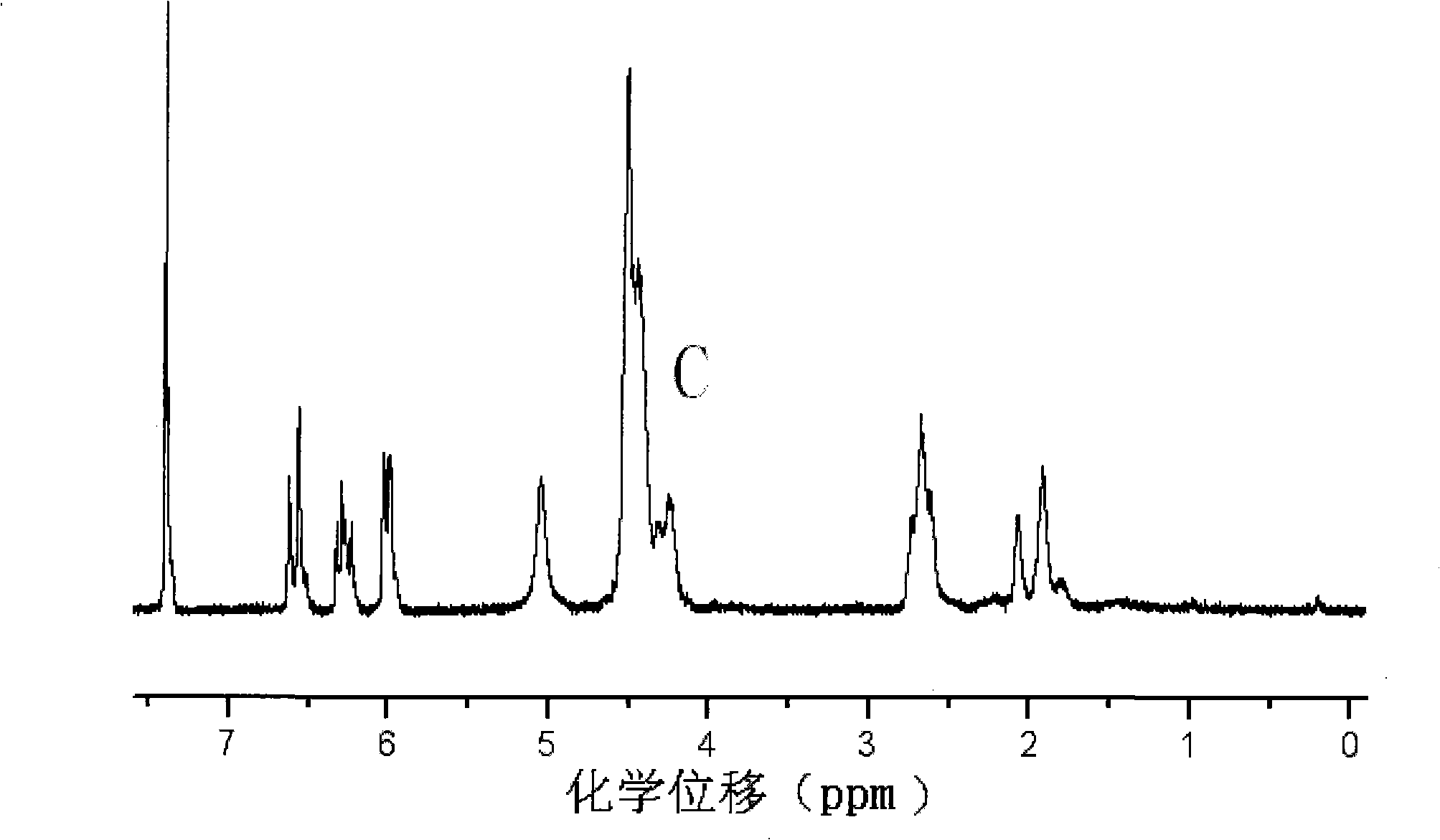

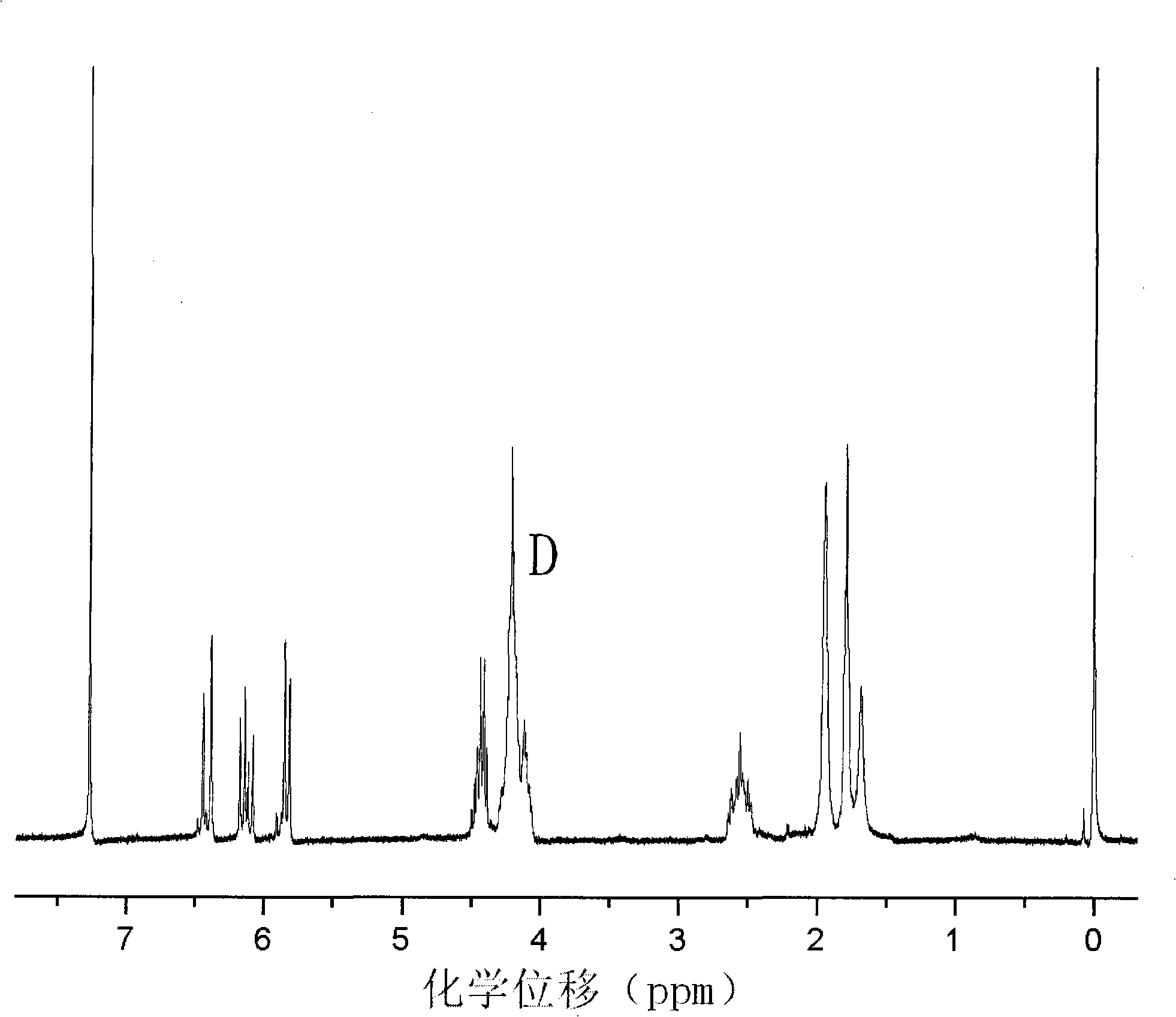

[0030] Under ice-water bath conditions, add 15.3g phosphorus oxychloride and 400mL ether to a three-necked flask reactor equipped with a condensation and stirring device, then add the ether solution containing 46.4g perfluorooctyl alcohol and 10.1g triethylamine to Slowly drop into the reactor at a rate of one drop per second, return to room temperature and stir for 8 hours after the dropwise addition; then add the ether solution containing 11.6g of hydroxyethyl acrylate and 10.1g of triethylamine into the above reaction mixture to continue the reaction for 24 hours, Then add 4.5g of butanediol and 10.1g of triethylamine in ether solution, stir at room temperature until the infrared phosphorus oxychloride absorption peak disappears; the reaction product is filtered, neutralized, washed with saturated sodium bicarbonate solution and distilled water successively, and separated , and the solvent was removed to obtain a light yellow solid, that is, perfluorooctyl phosphate acrylate...

Embodiment 2

[0038] Under ice-water bath conditions, add 15.3g of phosphorus oxychloride and 100mL ether to a three-necked flask reactor equipped with a condensation and stirring device, and then add the ether solution containing 10.0g of trifluoroethanol and 7.9g of pyridine at a rate of one drop per second Slowly add dropwise into the reactor, return to room temperature and stir for 8 hours after the dropwise addition; then add the ether solution containing 11.6g hydroxyethyl acrylate and 7.9g pyridine to the above reaction mixture and continue to react for 24 hours, then add 5.9g hexadiene Alcohol and 7.9g of pyridine ether solution, stirred at room temperature until the infrared phosphorus oxychloride absorption peak disappears; the reaction product is filtered, neutralized, washed with saturated sodium bicarbonate solution and distilled water successively, separated, and the solvent is removed to obtain light yellow The solid was trifluoroethyl phosphate acrylate monomer, and the yield...

Embodiment 3

[0042]Under ice-water bath conditions, add 15.3g phosphorus oxychloride and 400mL ether to the three-neck flask reactor equipped with condensation and stirring device, then add the ether solution containing 46.4g perfluorooctyl alcohol and 7.9g pyridine at a rate of Slowly add one drop into the reactor, return to room temperature and stir for 8 hours after the addition is complete; then slowly add the ether solution containing 20.8g of 1,5-pentanediol and 15.8g of pyridine into the above reaction mixture dropwise, and continue to react at room temperature to The absorption peak of the infrared phosphorus oxychloride group disappeared, then 15.8g of pyridine was added and cooled in an ice-water bath, and an ether solution containing 19.0g of acryloyl chloride was slowly added dropwise. After the dropwise addition, the reaction was continued at room temperature for 12 hours. The reaction product was filtered, neutralized, washed successively with saturated sodium bicarbonate solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com