Adsorption siphon separation process and siphon separation device with self-suction function

A separation device and siphon technology, which is applied in the feeding/discharging device of the settling tank, filtration separation, liquid separation, etc., can solve the difficulty of removing the filter cake from the filter medium for cleaning and regeneration, cannot realize continuous operation without power, and increase the filtration area and other problems, to achieve the effect of stable work, excellent effect and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

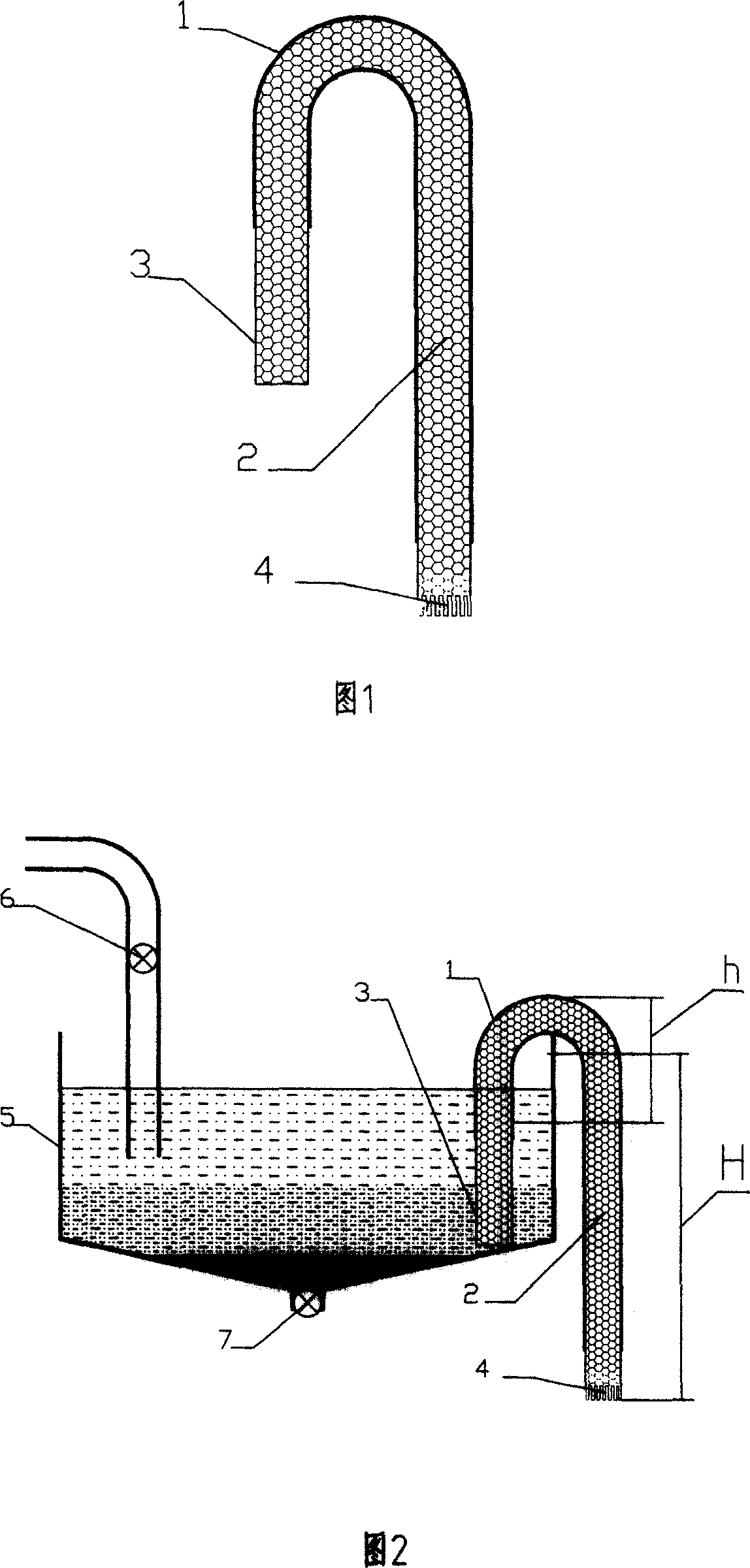

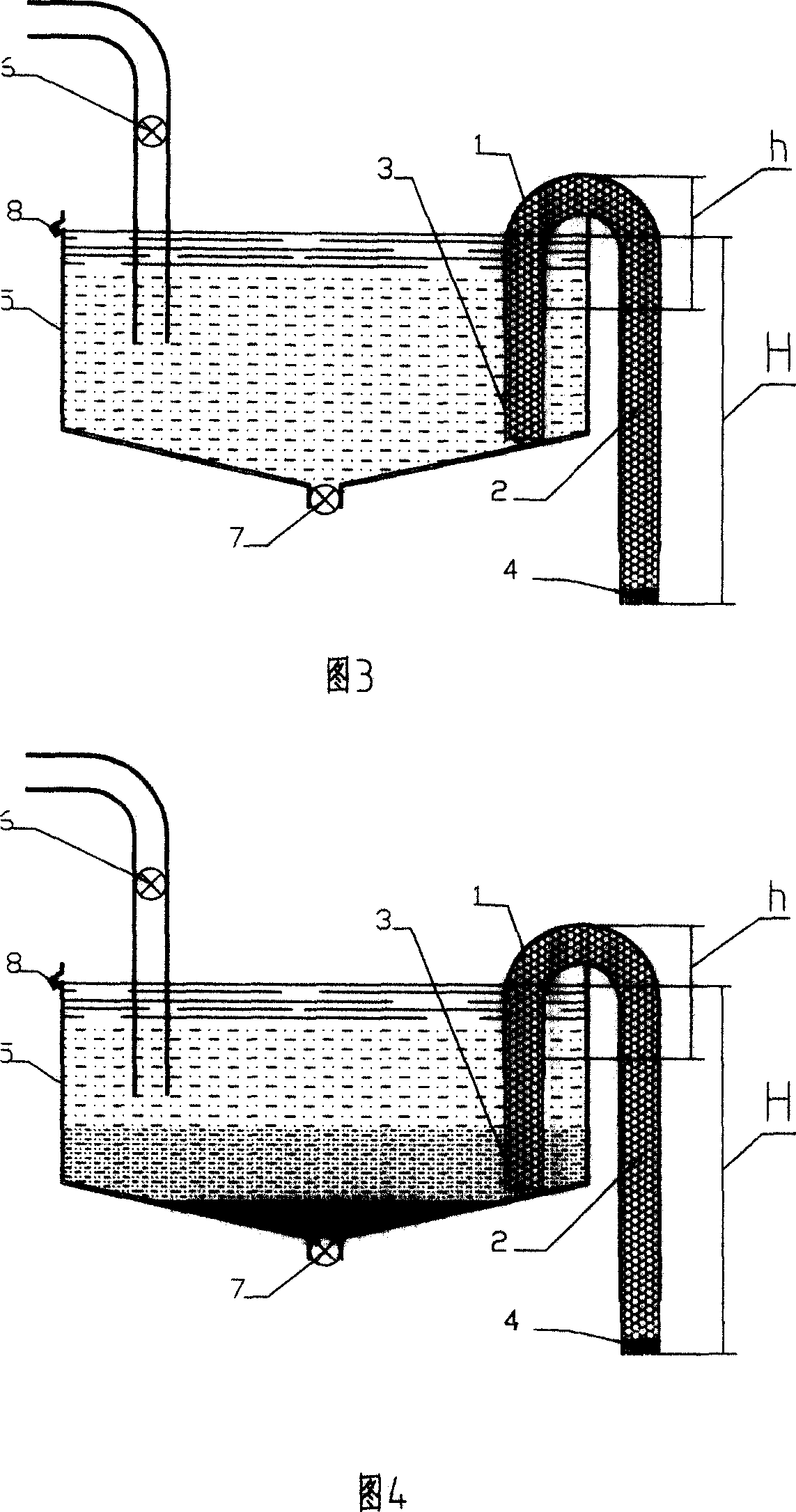

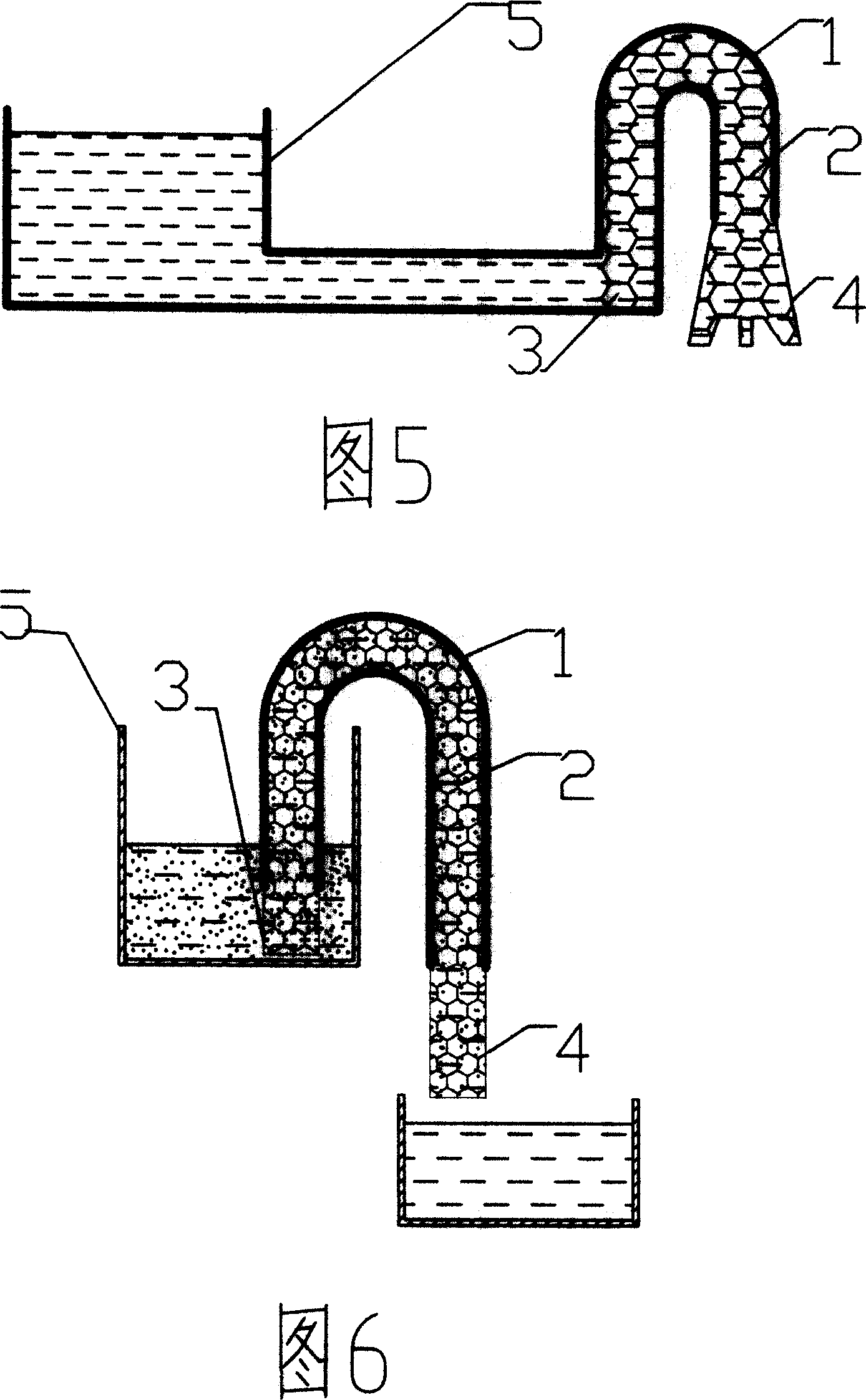

[0016] In Fig. 1, the adsorption siphon separation pipe (1) is composed of a siphon tube and an adsorption rod (2), the part where the adsorption rod extends out of the inlet end of the siphon tube is the adsorption head (3), and the part where the adsorption rod extends out of the outlet of the siphon tube is the liquid discharge head ( 4).

[0017] In the first embodiment shown in Fig. 2, it is expected that the effect of achieving inorganic electrodynamic solid-liquid separation is as follows: during work, the solid-liquid mixed slurry enters the container (5) through the feed valve (6), and the adsorption head (3) Start to inhale the water clear liquid and rise along the adsorption rod (2). When the liquid level rises to the point where the vertical distance from the inner vertex of the adsorption siphon separation pipe (1) is less than the self-priming height (h) of the adsorption siphon separation pipe, the water The clear liquid rises gradually and climbs over the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com