Novel aluminum alloy plate as well as preparation method and application thereof

An aluminum alloy plate and alloy technology, applied in the field of aluminum alloy plate, can solve the problems of surface brightness reduction, decorative effect discount, application limitation, etc., and achieve the effect of high tensile strength and good brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A new type of Al-Mg alloy, the proportion of each element in the Al-Mg alloy is: Mg: 0.8%; Si: 0.14%; Fe: 0.14%; Cu: 0.03%; Mn: 0.02%; Zn: 0.02% ; Ti: 0.02%; Al: balance.

[0034] The technical effect of this embodiment 1 is as follows:

[0035] 1. After polishing and oxidation, this new type of aluminum material has the same surface brightness as pure aluminum material, and because of its high Brinell hardness, tensile strength and yield strength, it can be widely used in the interior and exterior of automobiles. The decorative parts not only maintain a good bright effect, but also ensure the service life of the decorative parts.

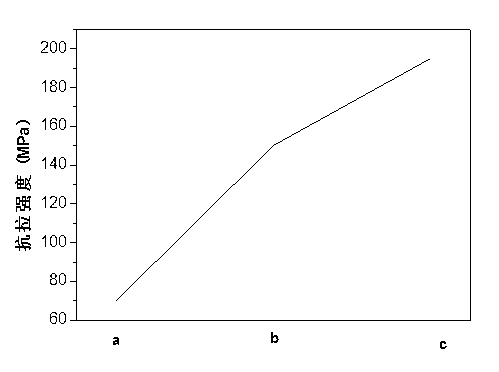

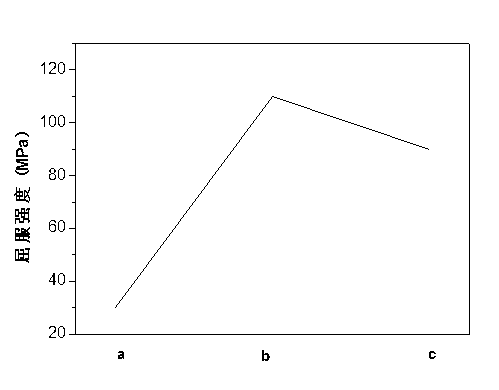

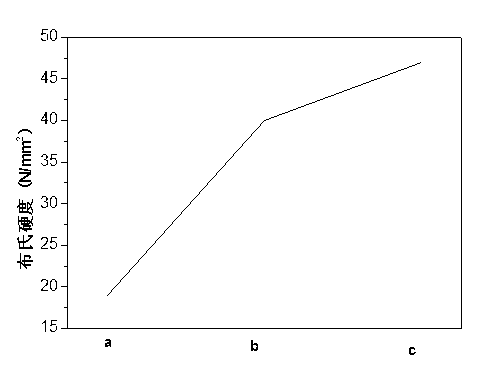

[0036] 2. This new type of aluminum material has good tensile strength, yield strength, and hardness at the same time, and its mechanical strength is similar to that of the 5-series aluminum plate. Figure 1-Figure 3 It is a graph of mechanical properties of pure aluminum, Al-Mg alloy, 5052H32 (Mg: 2.2 ~ 2.8) aluminum plate (the measured v...

Embodiment 2

[0038] A new type of Al-Mg alloy, the proportion of each element in the Al-Mg alloy is: Mg: 1.0%; Si: 0.14%; Fe: 0.14%; Cu: 0.03%; Mn: 0.02%; Zn: 0.02% ; Ti: 0.02%; Al: balance.

[0039] The technical effect of this embodiment 2 is basically similar to that of embodiment 1, except that by controlling the addition ratio of Mg, the yield strength of the aluminum alloy can be increased, while maintaining the good brightness of pure aluminum, and the surface gloss is less reduced after anodic oxidation The advantages.

[0040] The above-mentioned inventive materials can be applied to the manufacture of interior and exterior trim parts of automobiles, such as sill panels, bright trim strips, signs and the like. Take the door sill pedal of a car as an example: First, the aluminum plate is processed into a mirror surface after being machine-polished or electro-polished; Process, processed into products; finally, after chemical polishing, light emitting, anodizing, sealing and other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com