Cyanide-free silver plating brightening agent and preparing method thereof

A technology of silver light and solvent, which is applied in the field of cyanide-free silver plating, can solve the problems of poor coating appearance and non-bright appearance, and achieve better wear resistance, refined grains, and obvious bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

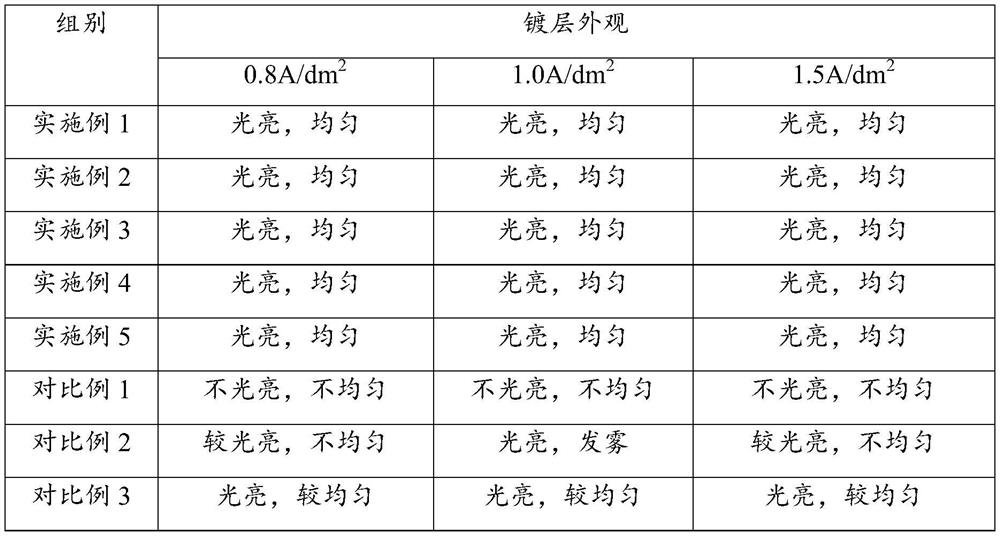

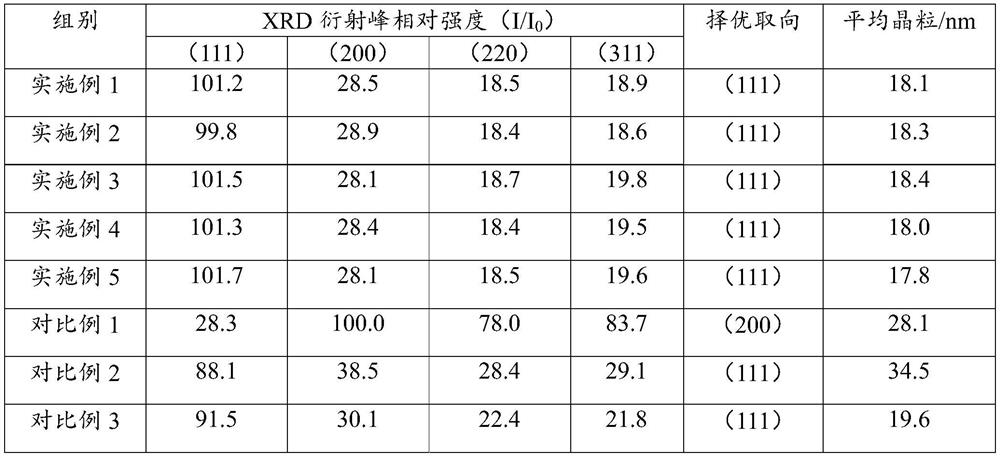

Examples

Embodiment 1

[0025] Embodiment 1, cyanide-free silver plating brightener of the present invention and preparation method thereof

[0026] Cyanide-free silver plating brightener of the present invention, with deionized water as solvent, comprises the component of following concentration: sodium dodecyl diphenyl sulfonate 10g / L, HEDTA 1g / L, potassium dihydrogen phosphate 0.5g / L , β-naphthol polyoxyethylene ether 10g / L, polyethylene glycol 10g / L, urea 10g / L, 1-benzyl-1,2,3,4-tetrahydroisoquinoline 10g / L and 2- Methyltetrahydrofuran-3-thiol 30g / L.

[0027] The preparation method of cyanide-free silver plating brightener of the present invention comprises the following steps:

[0028] S1. Measure the amount of sodium dodecyl dibenzene sulfonate, β-naphthol polyoxyethylene ether, polyethylene glycol and HEDTA into deionized water, stir until completely dissolved, the stirring speed is 100r / min, the stirring time Be 20min, obtain mixture A;

[0029] S2. Heat up to 40°C, measure the amount of 2...

Embodiment 2

[0031] Embodiment 2, cyanide-free silver plating brightener of the present invention and preparation method thereof

[0032] Cyanide-free silver plating brightener of the present invention, with deionized water as solvent, comprises the component of following concentration: sodium dodecyl diphenyl sulfonate 15g / L, HEDTA 1.5g / L, potassium dihydrogen phosphate 1.0g / L, β-naphthol polyoxyethylene ether 15g / L, polyethylene glycol 5g / L, urea 15g / L, 1-benzyl-1,2,3,4-tetrahydroisoquinoline 12g / L and 2 -Methyltetrahydrofuran-3-thiol 35g / L.

[0033] The preparation method of cyanide-free silver plating brightener of the present invention comprises the following steps:

[0034] S1. Measure the amount of sodium dodecyl dibenzene sulfonate, β-naphthol polyoxyethylene ether, polyethylene glycol and HEDTA into deionized water, stir until completely dissolved, the stirring speed is 150r / min, the stirring time Be 20min, obtain mixture A;

[0035] S2. Heat up to 40°C, measure the amount of ...

Embodiment 3

[0037] Embodiment 3, cyanide-free silver plating brightener of the present invention and preparation method thereof

[0038] Cyanide-free silver plating brightener of the present invention, with deionized water as solvent, comprises the component of following concentration: sodium dodecyl diphenyl sulfonate 20g / L, HEDTA 2.0g / L, potassium dihydrogen phosphate 1.5g / L L, β-naphthol polyoxyethylene ether 22g / L, polyethylene glycol 8g / L, urea 15g / L, 1-benzyl-1,2,3,4-tetrahydroisoquinoline 13g / L and 2 -Methyltetrahydrofuran-3-thiol 40g / L.

[0039] The preparation method of cyanide-free silver plating brightener of the present invention comprises the following steps:

[0040] S1. Measure the amount of sodium dodecyl dibenzene sulfonate, β-naphthol polyoxyethylene ether, polyethylene glycol and HEDTA into deionized water, stir until completely dissolved, the stirring speed is 170r / min, the stirring time Be 25min, obtain mixture A;

[0041]S2. Warm up to 45°C, measure the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com