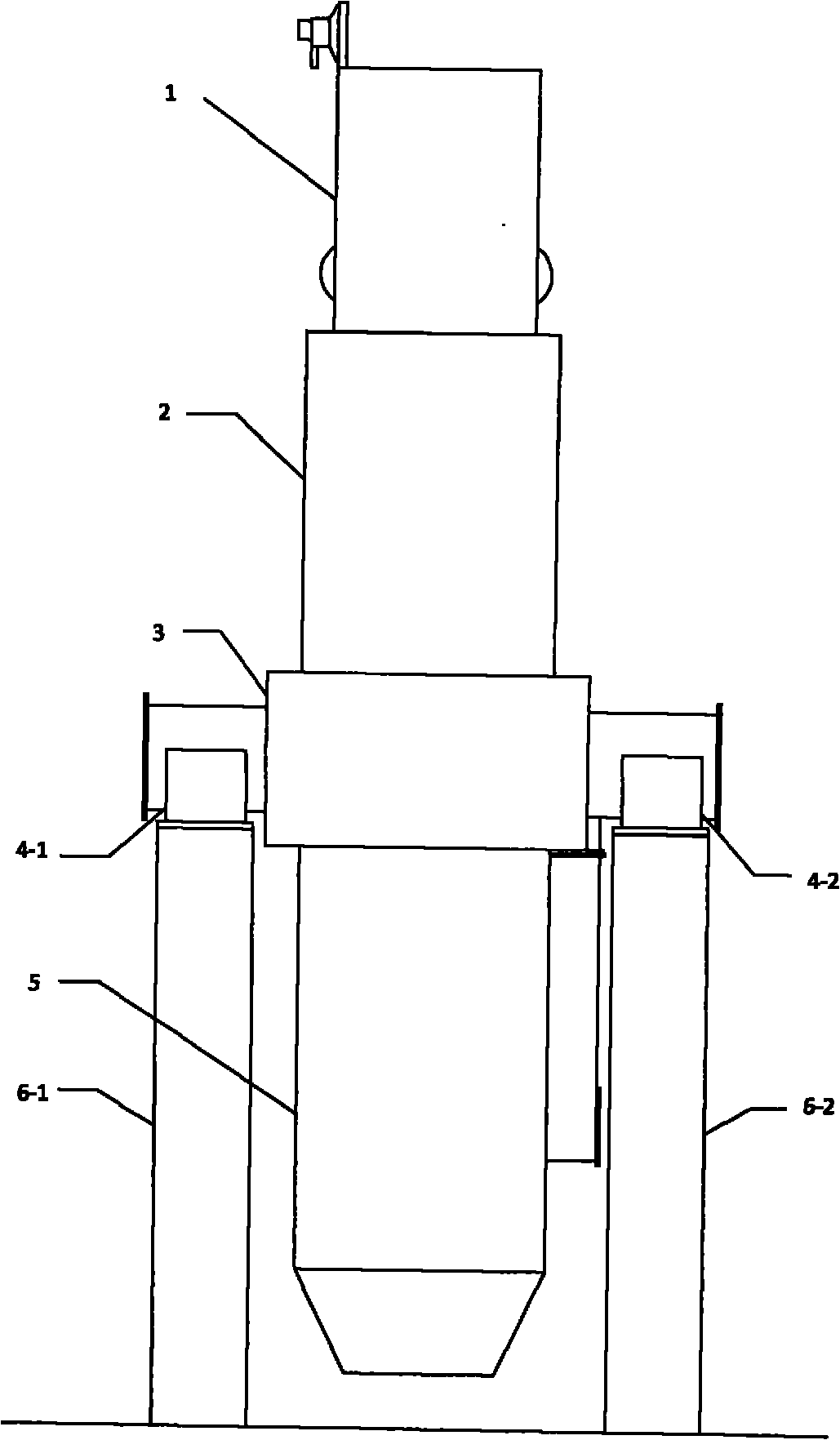

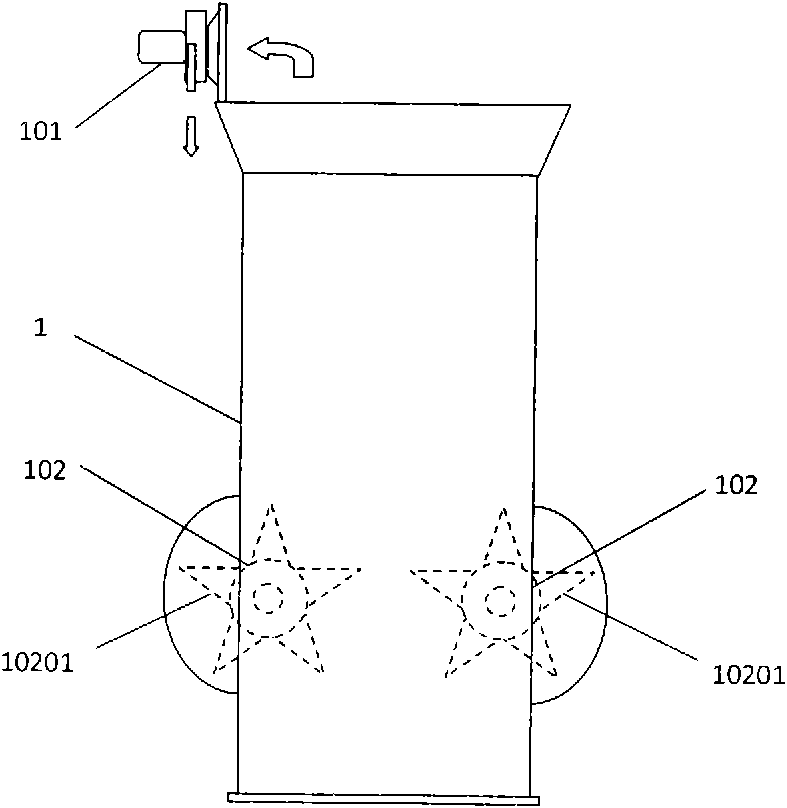

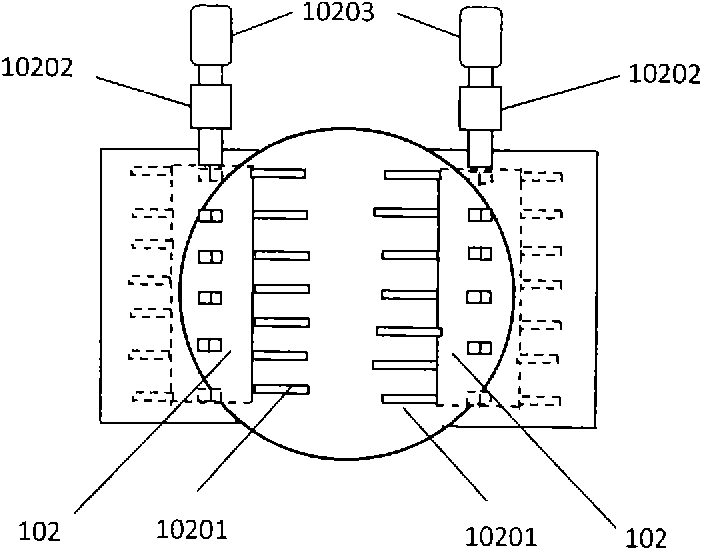

Two-stage plasma gasifying, melting and cracking method and device of waste containing organic matters

A plasma, gasification and melting technology, applied in the field of gasification, melting and cracking, can solve the problems of high energy consumption and fly ash, and achieve the effect of wide application field, no impact on efficiency, and high degree of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Medical waste, calorific value HHV (higher calorific value) 15MJ / kg, processing capacity 500kg / hr, composition (%wt): 50C, 7H, 25.7O, 1N, 0.5S, 0.8Cl, 15ASH (ash), 35Moisture ( Humidity); DC plasma arc power 100kW; obtained vitrified body about 75kg / hr; syngas generation 1200℃, 1550NM 3 / hr, synthetic gas chemical heat dry basis HHV4.14MJ / NM 3, wet basis HHV3.39MJ / NM 3 , sensible heat 2932MJ / hr; synthesis gas molar ratio (% mol): 0.01CH 4 , 0.00C 2 h 2 , 0.00C 2 h 4 , 13.76CO, 7.82CO 2 , 15.17H 2 , 0.12HCl, 18.19H 2 O, 0.08H 2 S, 44.87N 2 ; Dioxin emission in tail gas after purification and utilization of syngas 3 .

Embodiment 2

[0058] Rice husk, calorific value HHV (higher calorific value) 10.2MJ / kg, capacity, 1000kg / hr, composition (%wt): 32.4C, 4.6H, 38.5O, 0.6N, 0.2S, 23.7ASH, 15Moisture; DC The plasma arc power is 200kW; the obtained glass body is about 240kg / hr; the synthesis gas is generated at 1200°C, 2211NM 3 / hr, syngas chemical heat dry basis HHV (high heating value) 3.72MJ / NM 3 , wet basis HHV3.02MJ / NM 3 , sensible heat 4329MJ / hr; synthesis gas molar ratio (% mol): 0.01CH 4 , 0.00C 2 h 2 , 0.00C 2 h 4 , 14.33CO, 11.02CO 2 , 11.57H 2 , 0.00HCl, 18.83H 2 O, 0.04H 2 S, 44.20N 2 .

Embodiment 3

[0060] Abandoned computer motherboards with components, organic matter mainly brominated epoxy resin 40%wt, inorganic oxides 30%wt, metal 30%wt, after two-stage plasma gasification melting cracking treatment, DC plasma arc power consumption is about 750kWh / T, 295kg / T of mixed metal ingots can be obtained, the metal recovery rate is 98.5%, the glass body is about 320kg / T, and about 40kg / T of carbonate-based thinner slag containing K and or Na is required.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com