A blank casting process for high creep rate and high strength hydraulic motor shell

A technology of hydraulic motor and casting process, which is applied in the field of motor casting, and can solve the problems affecting the casting tensile strength and hardness of the hydraulic motor shell, reducing the absorption rate of vermative agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

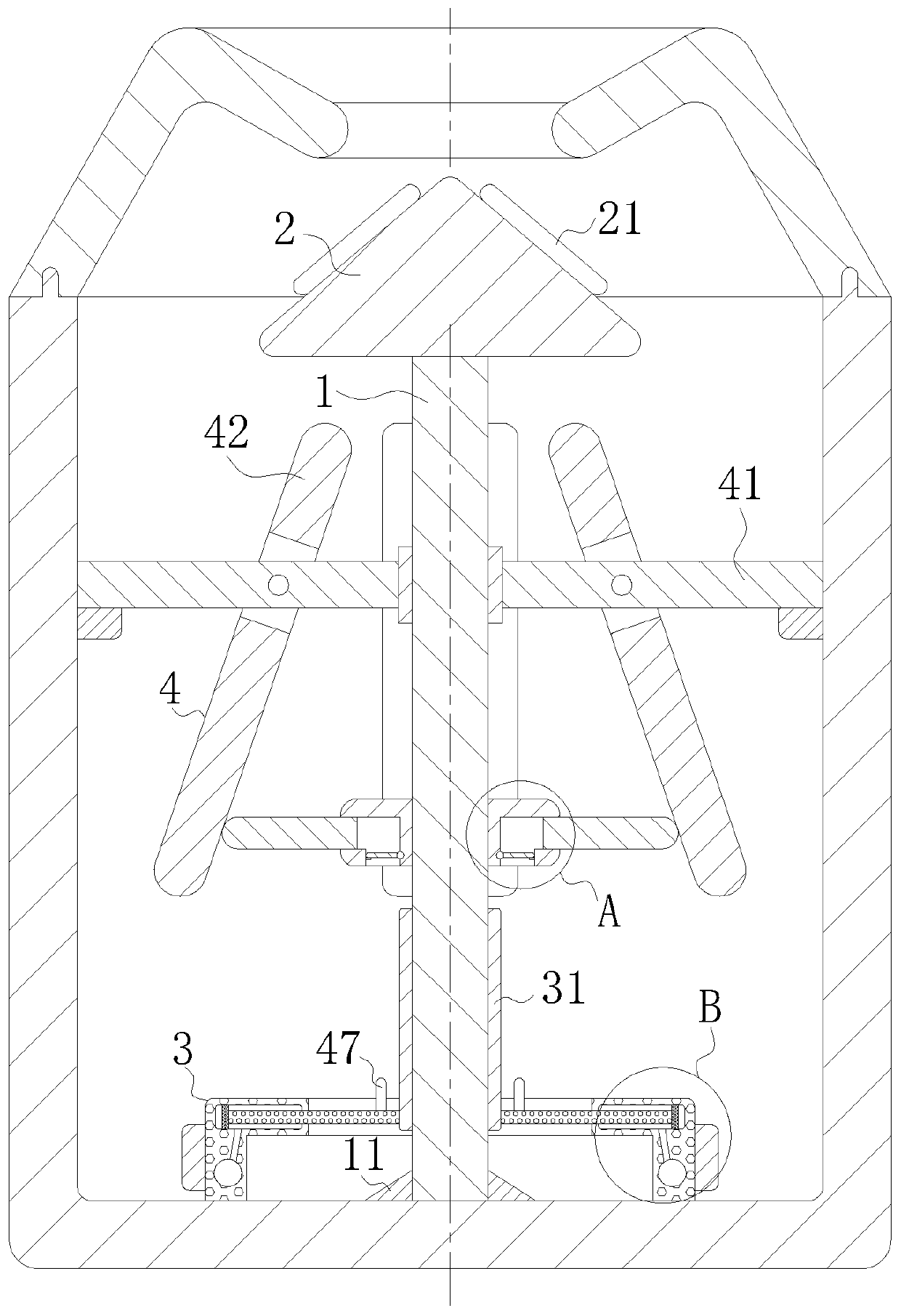

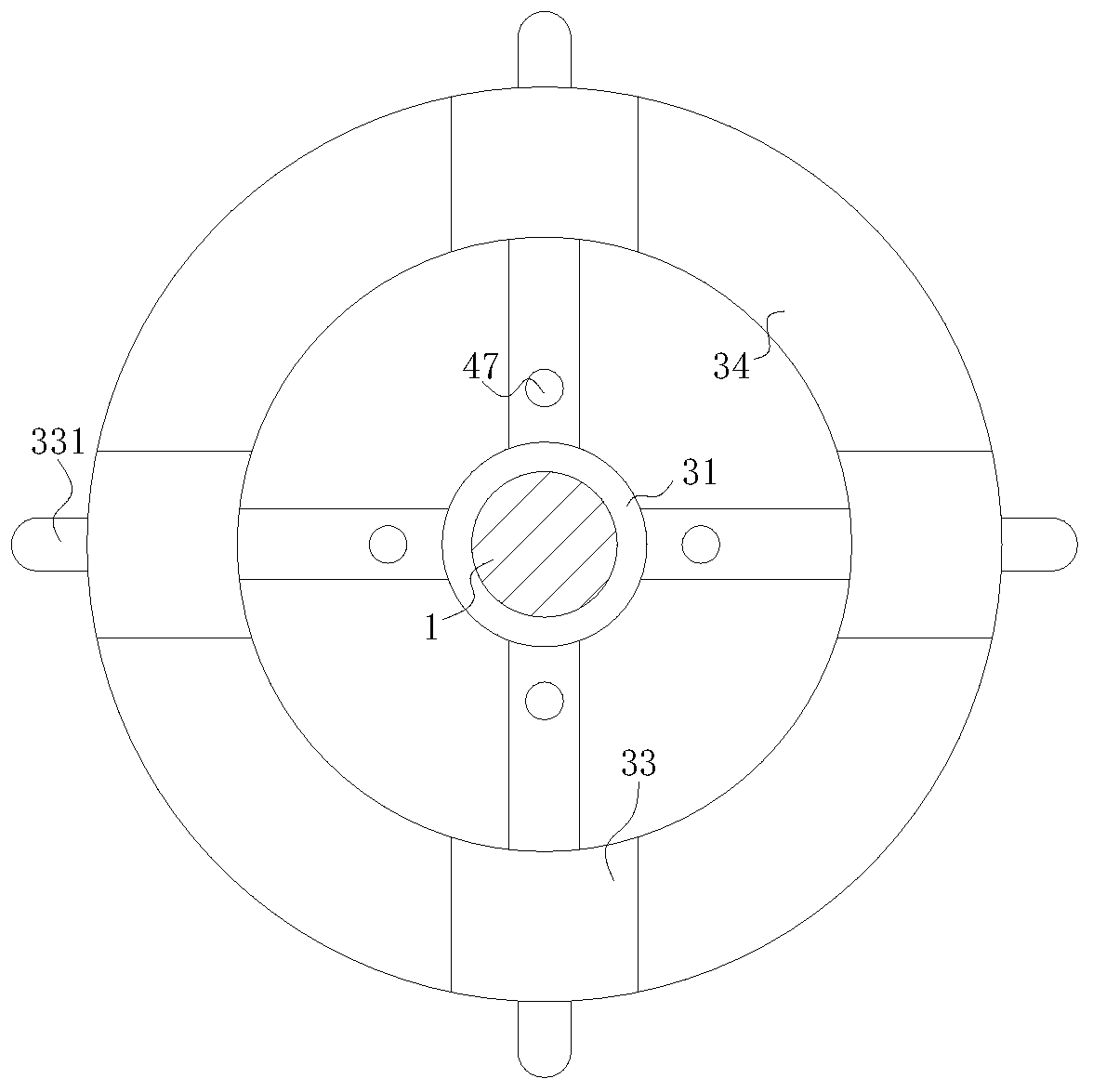

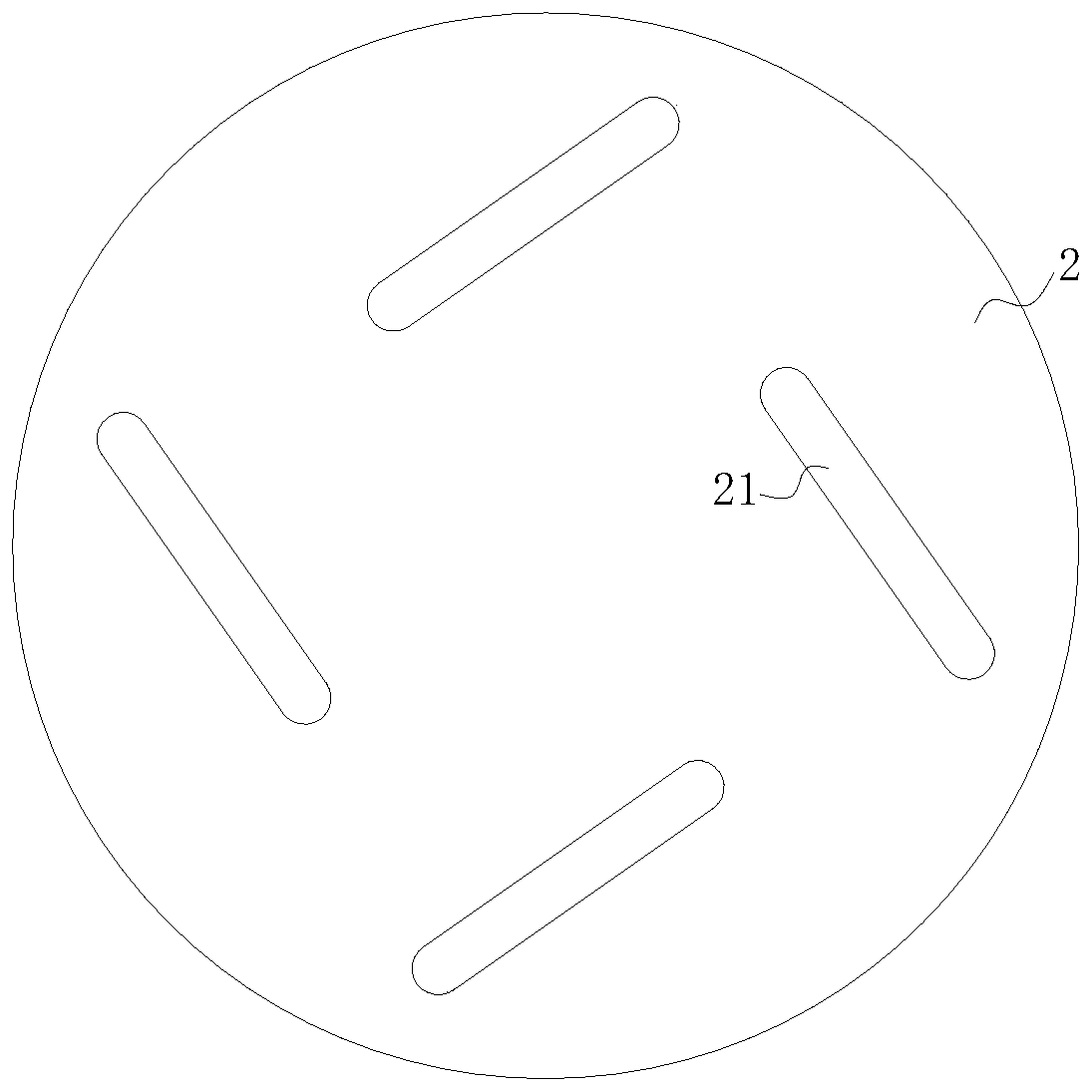

[0025] use Figure 1-Figure 5 A blank casting process for a high-creep rate high-strength hydraulic motor body shell according to an embodiment of the present invention is described as follows.

[0026] Such as Figure 1-Figure 5 As shown in the present invention, a high-creep rate high-strength hydraulic motor shell blank casting process, the process includes the following steps:

[0027] S1: Put the prepared vermiser and inoculant into the ladle and place it on the bottom of the ladle, then put the vermiser into the ladle, and pass the vermiser through the isolation mechanism at the lower end of the vermiser Covering and wrapping with inoculants;

[0028] S2: After the vermiser and inoculant in S1 are covered and wrapped by the isolation mechanism, the molten iron is passed into the ladle through the upper end of the ladle, and the molten iron is scattered to the bottom of the ladle through the dispersing mechanism in the middle of the vermin device Bottom, and use the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com