High-strength weather-resistant paint and preparation process thereof

A high-strength weather-resistant paint and preparation technology, which is applied in coatings and other directions, can solve the problems of coatings being easily contaminated with dust, unsuitable for construction, and accelerating the process of water evaporation, etc., to achieve the effects of prolonging life, good pencil hardness, and improving acid rain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

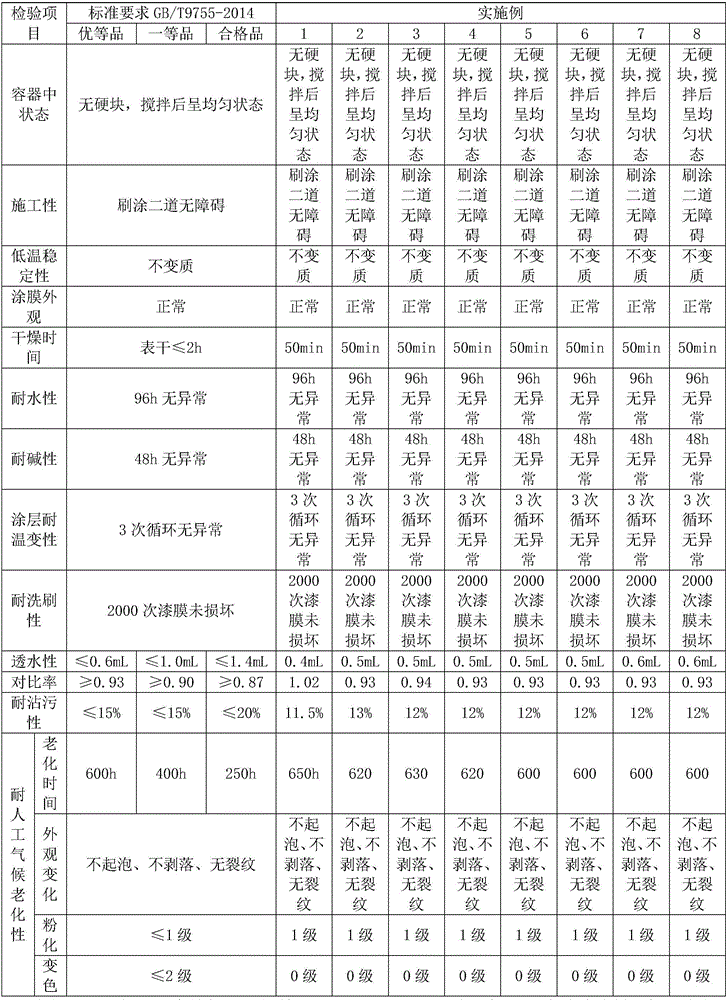

[0031] Embodiment 1: high-strength weather-resistant paint.

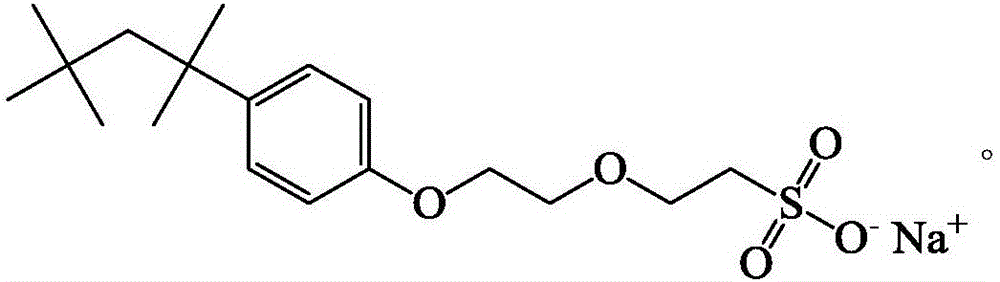

[0032] The raw materials include: 25Kg of aqueous emulsion, 20Kg of rutile titanium dioxide, 20Kg of high-purity silica powder, 18Kg of water, 5Kg of hydroxyethyl cellulose, 5Kg of ethylene glycol, 0.00015Kg of dispersant, 0.0002Kg of wetting agent, and defoamer 0.0001Kg, film-forming aid 0.00015Kg, pH regulator 0.0002Kg, leveling agent 0.00015Kg, thickener 0.0001Kg.

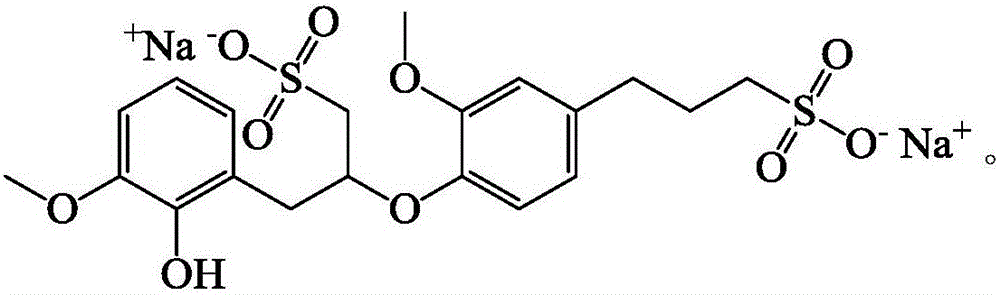

[0033] Wherein, the aqueous emulsion is prepared by polymerizing acrylate hard monomers, acrylate soft monomers, acrylate functional monomers and water in a 60 Coy ray field in a certain proportion; wherein, the radiation dose is 9KGy, and the dose is not The uniformity is less than 1.2; the acrylic hard monomer is methacrylic acid, the acrylic soft monomer is butyl acrylate, and the acrylic functional monomer is itaconic acid and N-methylol acrylamide; the The mass ratio of methacrylic acid, butyl acrylate, itaconic acid, N-methylolacrylamide and wa...

Embodiment 2

[0038] Embodiment 2: the difference between embodiment 2 and embodiment 1 is that the rotating speed in Step1 is 600r / min.

Embodiment 3

[0039] Embodiment 3: The difference between embodiment 3 and embodiment 1 is that the rotating speed in Step2 is 1100r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com