A kind of processing method of piston forging die

A processing method and mold technology, applied in the field of mold processing, can solve problems such as difficult processing and short service life of piston molds, and achieve the effects of reducing electrode consumption, improving processing efficiency and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

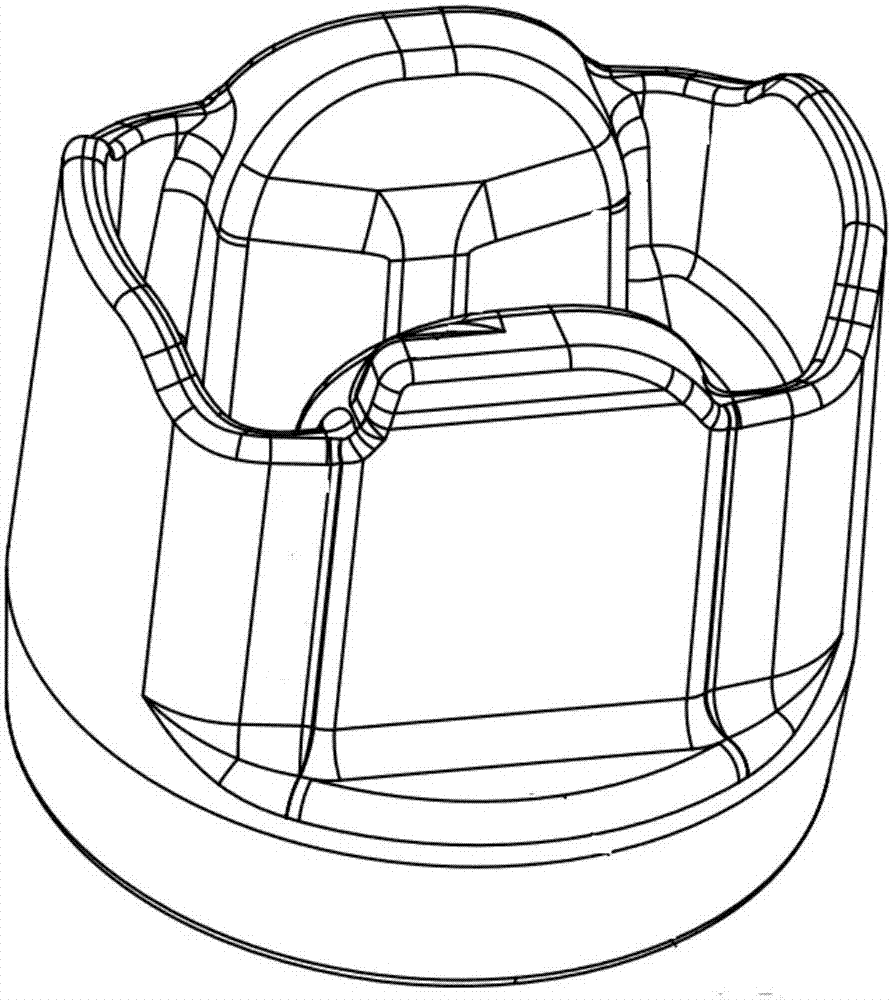

[0035] combine figure 1 , the processing method of a kind of piston forging die of the present embodiment, its processing step is:

[0036] Step 1. Raw material preparation, using a round bar blank to prepare for forging; the composition of the round bar blank is calculated by weight percentage: C: 0.43%, Si: 1.10%, Mn: 0.42%, S: ≤0.010%, P: ≤ 0.015%, Cr: 5.0%, Ni: 0.08%, Cu: 0.010%, Mo: 1.25%, and the balance is Fe.

[0037] Step 2. Forging the material with three piers and three pulls, the forging ratio of the round bar blank to the blank after forging is 3.8;

[0038] The specific forging process is as follows: heating the blank to 1090°C for the first pier thickening and elongation forging, the forging ratio is 1.7, which is the height ratio after one pier thickening and elongation processing; then the blank Heating to 860°C, carry out the second thickening and elongating forging, the forging ratio is 1.6; after the second forging, heat the workpiece to 860°C, and perfor...

Embodiment 2

[0064] A kind of processing method of automobile one-axis forging mold of the present embodiment, its processing steps are:

[0065] Step 1. Raw material preparation, using a round bar blank to prepare for forging; the composition of the round bar blank is calculated by weight percentage: C: 0.41%, Si: 1.08%, Mn: 0.42%, S: ≤0.010%, P: ≤ 0.015%, Cr: 5.2%, Ni: 0.08%, Cu: 0.010%, Mo: 1.25%, and the balance is Fe.

[0066] Step 2. Forging the material with three piers and three pulls, the forging ratio of the round bar blank to the forged blank is 4;

[0067] The specific forging process is as follows: heating the blank to 1100°C for the first pier thickening and elongation forging with a forging ratio of 1.8; then heating the blank to 900°C for the second pier thickening and elongation forging, The forging ratio is 1.6; after the second forging, the workpiece is heated to 860°C, and the third forging pier is thickened and elongated, and the forging ratio is 1.4; after the third ...

Embodiment 3

[0080] A kind of processing method of automobile one-axis forging mold of the present embodiment, its processing steps are:

[0081] Step 1. Raw material preparation, using a round bar blank to prepare for forging; the components of the round bar blank are calculated by weight percentage: C: 0.42%, Si: 1.08%, Mn: 0.41%, S: ≤0.010%, P: ≤ 0.015%, Cr: 5.0%, Ni: 0.10%, Cu: 0.009%, Mo: 1.25%, and the balance is Fe.

[0082] Step 2. Forging the material with three piers and three pulls, the forging ratio of the round bar blank to the forged blank is 4;

[0083] The specific forging process is as follows: heating the blank to 1100°C for the first thickening and elongating forging with a forging ratio of 1.8; then heating the blank to 880°C for the second thickening and elongating forging. The forging ratio is 1.6; after the second forging, the workpiece is heated to 880°C, and the third forging pier is thickened and elongated, and the forging ratio is 1.4; after the third forging, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com