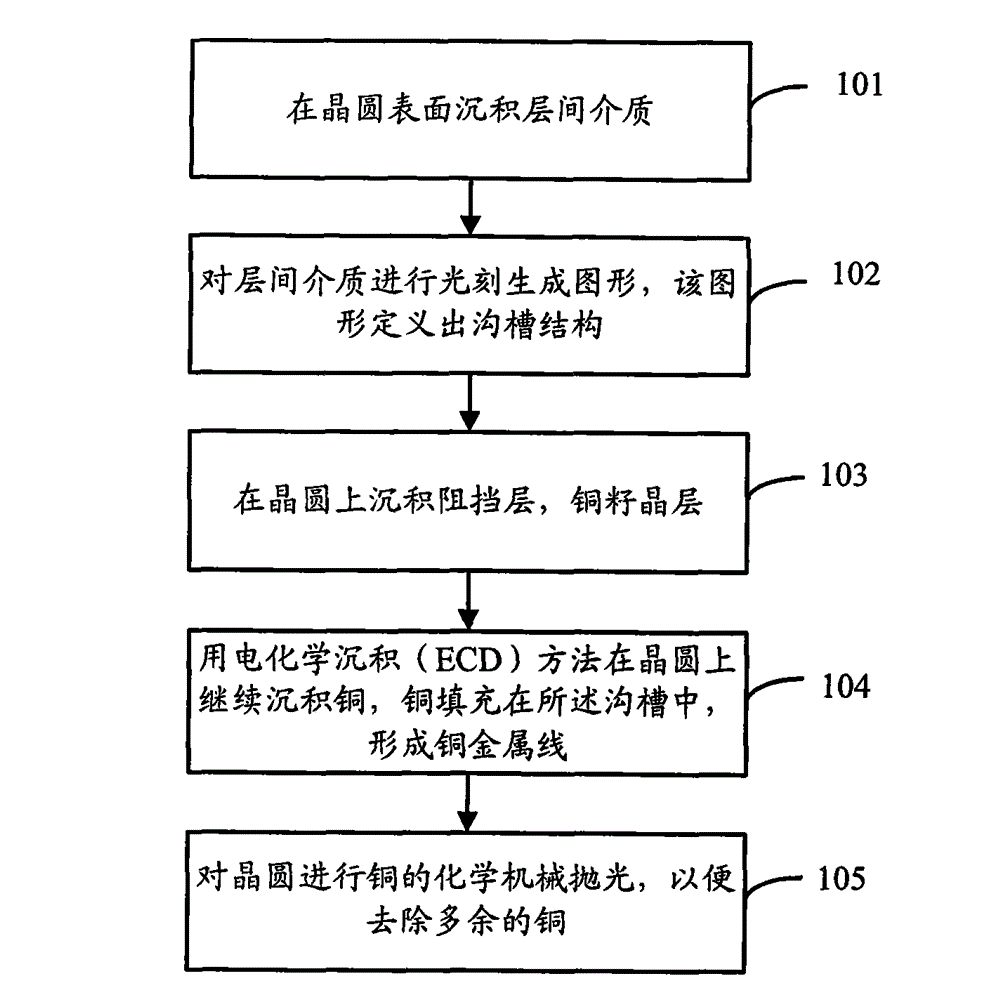

Method for constructing copper wire on wafer and chemical mechanical polishing (CMP) method for copper

A copper metal and wafer technology, which is applied in the field of semiconductor integrated circuit manufacturing, can solve the problems of depression at the metal wire, damage to the flatness of the wafer surface, and adverse effects of the conductive performance of the metal wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

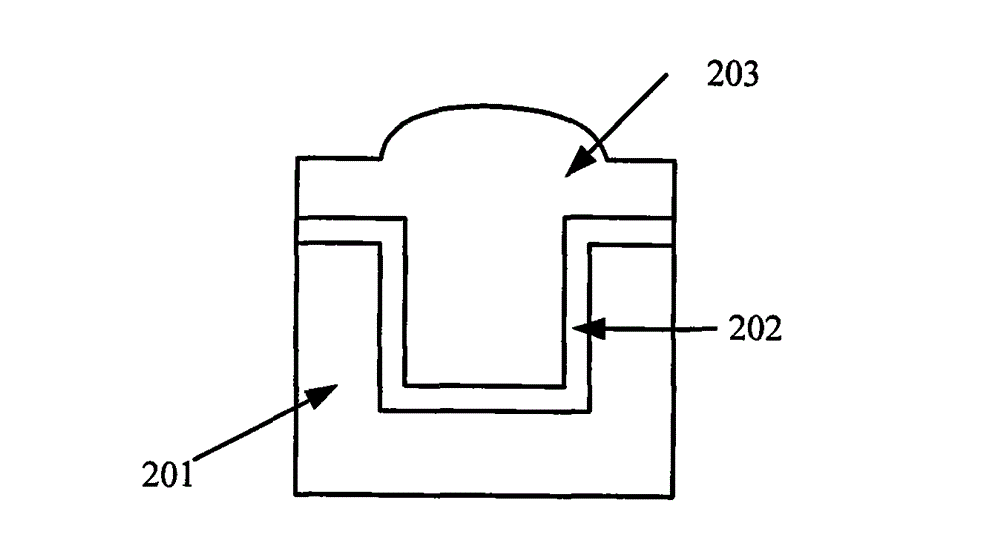

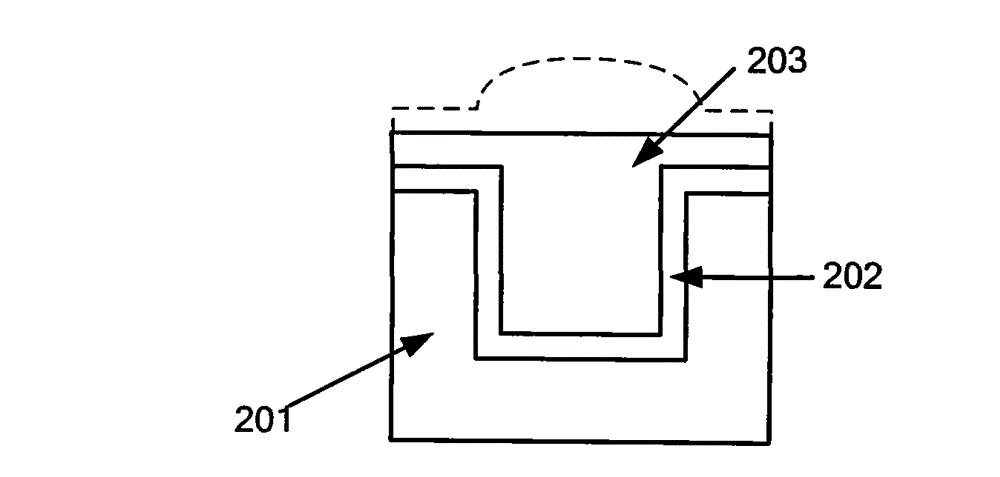

[0044] In the prior art, the main reason for causing the depression at the copper metal line is that the MRR difference between the interlayer dielectric and copper is relatively large. The key point of the method for constructing copper metal lines on a wafer proposed by the present invention is that after the first interlayer dielectric is deposited on the surface of the wafer, the second interlayer dielectric is additionally deposited, and the material constituting the second interlayer dielectric The hardness is smaller than that of the material constituting the first interlayer medium. When the Cu-CMP process is performed, the second interlayer dielectric is removed together with copper, and the MRR of the second interlayer dielectric is closer to the MRR of copper than the MRR of the original first interlayer dielectric, which can effectively reduce The degree of dishing at the copper metal line after CMP.

[0045] In order to make the purpose, technical solution and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com