Building construction plastic tube bending device

A bending device and construction technology, applied in the field of single plastic pipe bending device and plastic pipe bending device in construction construction, can solve the problems of low efficiency and increased difficulty of pre-embedded operation, and achieve wide adaptability, simple structure, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

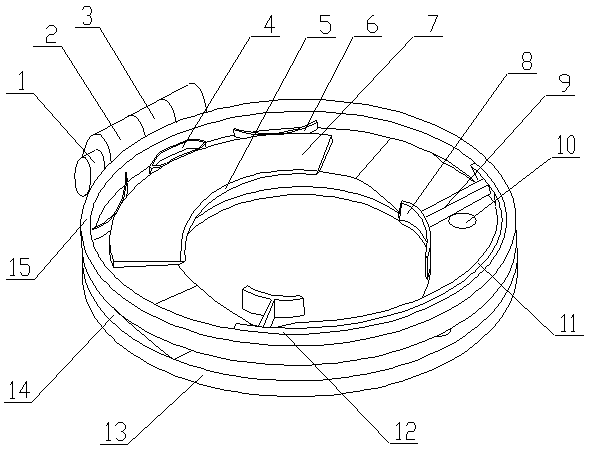

[0024] A plastic pipe bending device for building construction of the present invention is realized in the following way: when in use, when bending the plastic pipe, first install and fix the base (13) on the work base (13) through a plurality of fixing holes (10) Then put one end of the plastic tube through the inner ring of the base (13) and the inner ring of the traction ring (15), so that the bending position corresponds to the heating plate (11), and the inner sides of the two outer support plates (8) are respectively Fitting with the outside of the plastic tube, the plastic tube at one end of the inner support plate (7) is squeezed and deflected, and the two arc-shaped shrapnels (6) are deformed to varying degrees, thereby making the inner support plate (7) and the plastic tube The outer side of the tube is tightly fitted, and then the plastic tube is clamped and fixed, and then the heating plate (11) is heated to heat the bending position of the plastic tube to soften th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com