Cleaning blade and image forming apparatus

A technology for cleaning scrapers and images, which is applied in the fields of electric recording technology using charge patterns, equipment for electric recording technology using charge patterns, and electrography, etc., to achieve the effect of suppressing streaks and reducing uneven wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

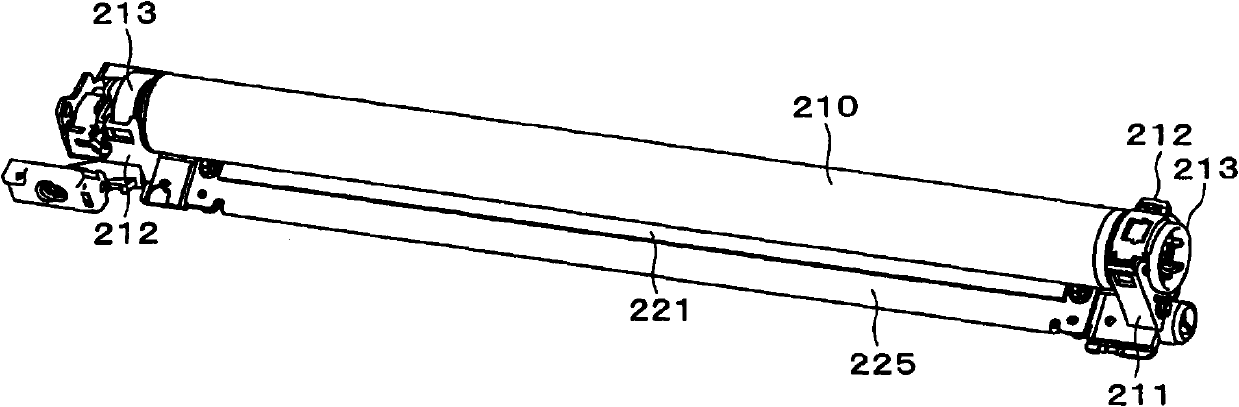

[0049] The cleaning blade was produced by integrally molding the following parts by centrifugal molding: a cleaning layer made of polyurethane resin having a thickness of 0.5 mm, a hardness of 78°, and an impact resilience of 43%; and a thickness of 1.4 mm, a hardness of The back layer made of polyurethane resin was 63°, the permanent set (tensile set) was 0.5%, and the impact resilience was 33%. A plurality of cleaning blades were produced in which the surface roughness Ra of the cleaning layer was different from each other.

[0050] The respective cleaning blades thus produced were installed in the image forming apparatus. The edge of the cleaning blade was cut into the photoreceptor by 1.2 mm, and the angle formed by the cleaning blade and the tangent to the surface of the photoreceptor was set to 26°. Printing was performed on 7000 A4-size sheets conveyed in the longitudinal direction in an environment of a temperature of 28°C and a humidity of 85% and an environment of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com