Steel pipe paint spraying processing equipment

A technology for processing equipment and steel pipes, which is applied in the field of steel pipe painting processing equipment, and can solve problems such as the depression of the outer wall of the steel pipe, the steel is easily corroded or damaged, and the protection ability of the paint at the depression is thinned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

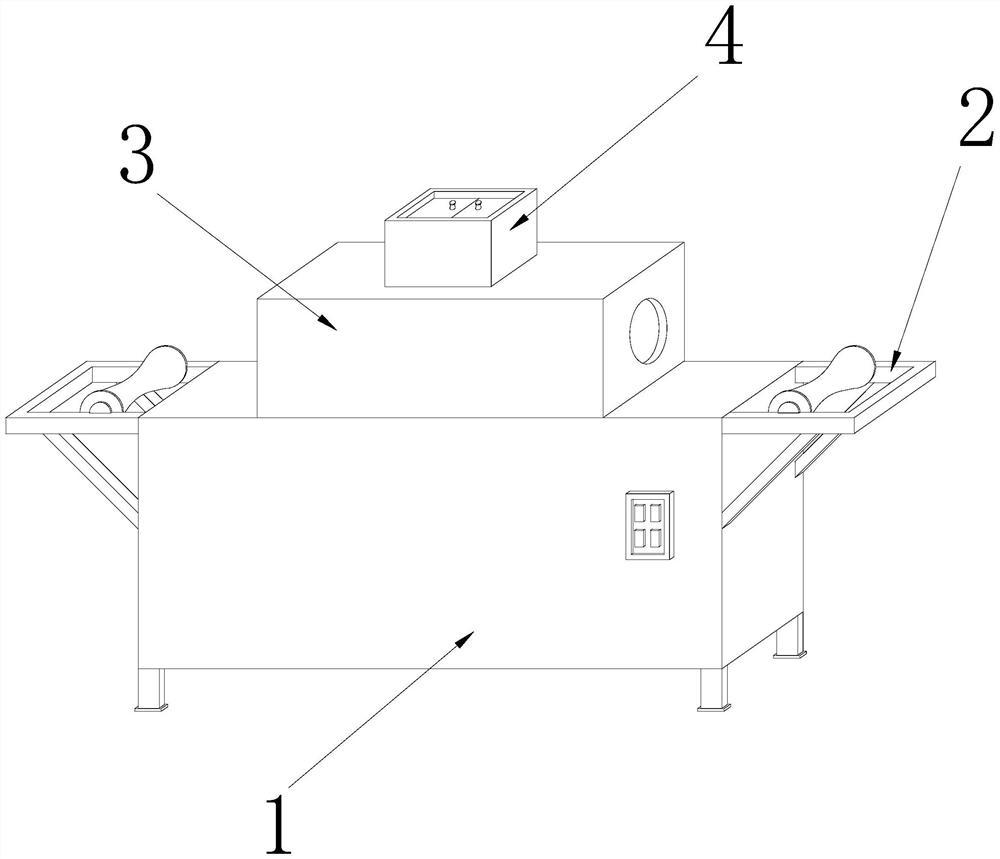

[0026] like Figure 1-Figure 5 As shown, the present invention provides a steel pipe painting processing equipment, the structure of which includes a body 1, a receiving shaft 2, a paint spraying device 3, and a paint storage box 4. Both ends of the receiving shaft 2 are movably engaged on both sides of the top of the body 1. The bottom of the paint spraying device 3 is welded to the center of the top of the body 1 , and the bottom of the paint storage box 4 is fitted and connected to the inside of the top of the paint spraying device 3 .

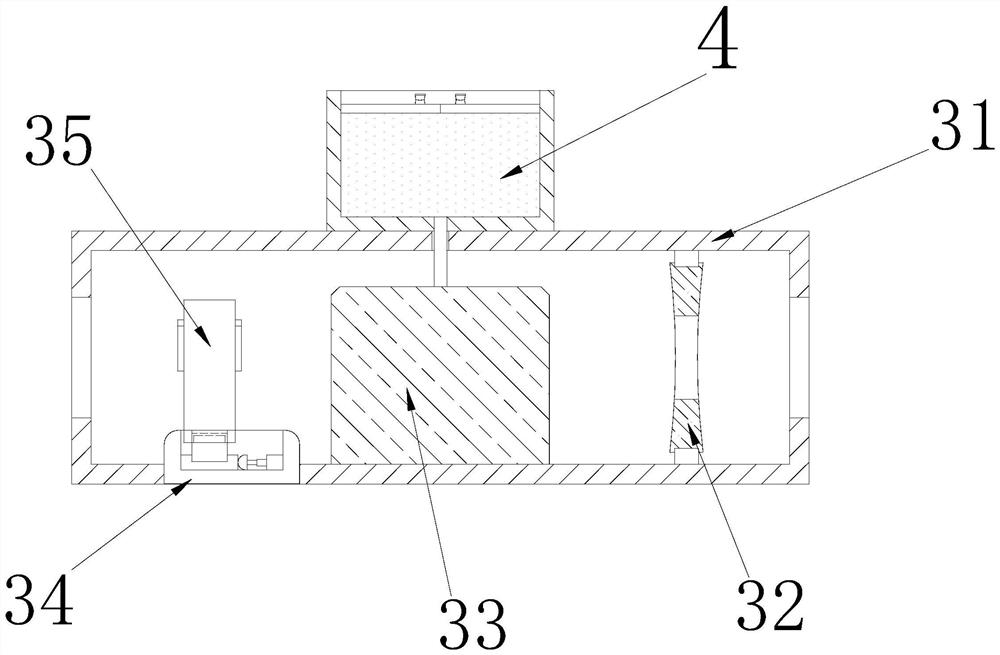

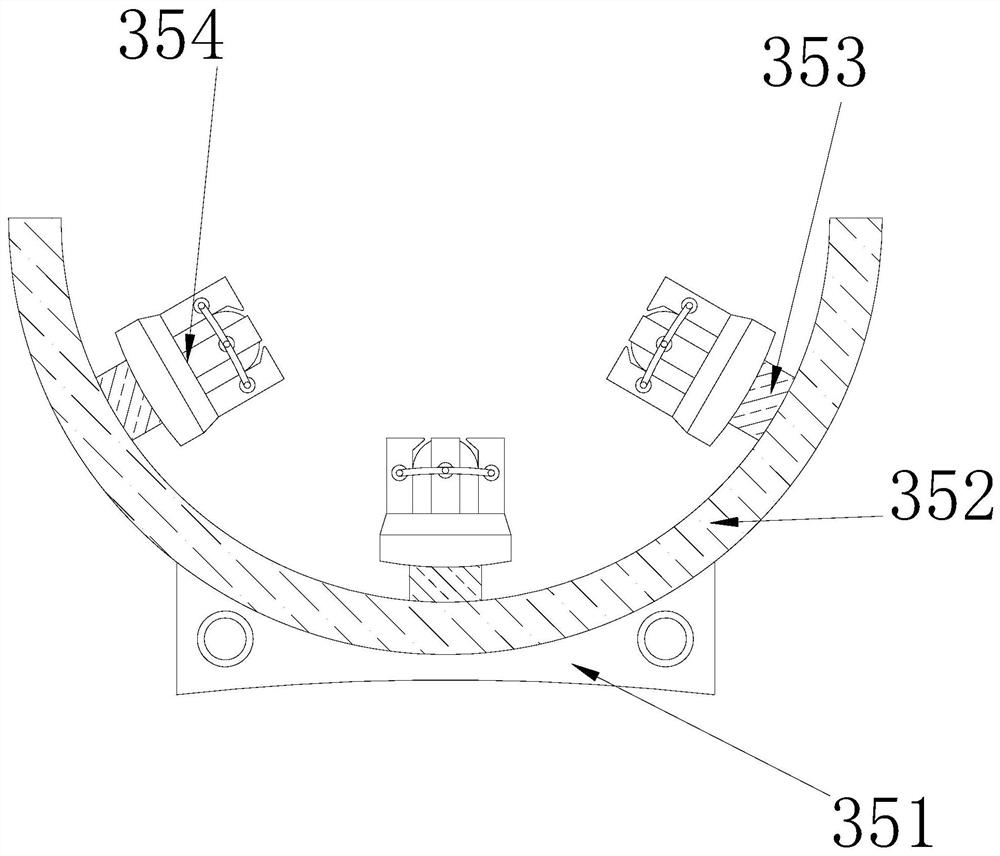

[0027] The painting device 3 includes a housing 31, a limiting ring 32, a painting block 33, a pushing block 34, and a clamping device 35. The outer wall of the limiting ring 32 is embedded and connected to the right side of the inner wall of the housing 31. The bottom end is fitted and connected to the center of the bottom end of the housing 31 , the periphery of the bottom end of the push block 34 is engaged with the inner left side of th...

Embodiment 2

[0034] like Figure 6-Figure 7 Shown:

[0035] Wherein, the scraping mechanism a3 includes a fixed block a31, an elastic strip a32, and a scraper a33, the end of the elastic strip a32 is embedded and connected to the upper and lower ends of the fixed block a31, and the outer wall of the scraper a33 is fitted and connected to the fixed block At the center of the end wall on the side of a31, four scrapers a33 are arranged and distributed in a circular array on the inner wall of the elastic bar a32, which makes the scraping effect of the scraper a33 more uniform and effective.

[0036]Wherein, the scraper a33 includes a block c1, a convex line c2, and a convex ball c3, the bottom end of the convex line c2 is embedded and connected to the top surface of the block c1, and the convex ball c3 is fitted and connected to the convex line c2 On the side, there are twenty-five convex balls c3 and they are evenly distributed on the upper surface of the block c1. This distribution makes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com