Helirota plane

A rotorcraft and rotor technology, applied in the field of aviation aircraft, can solve the problems of low efficiency, complex power system, and small pitch adjustment range of high efficiency, so as to reduce wear and fatigue loss, wide pitch adjustment range, and improve flight safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

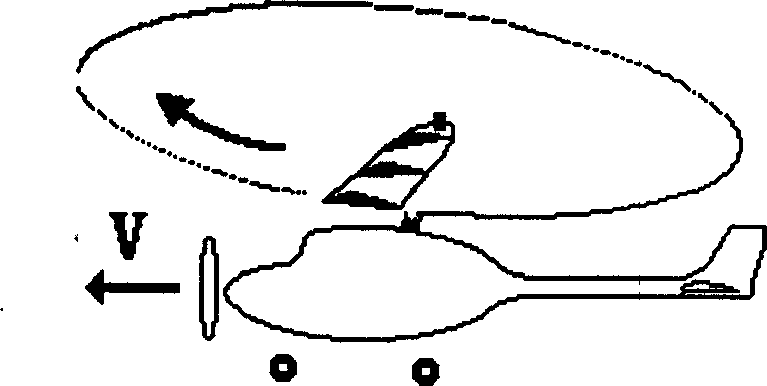

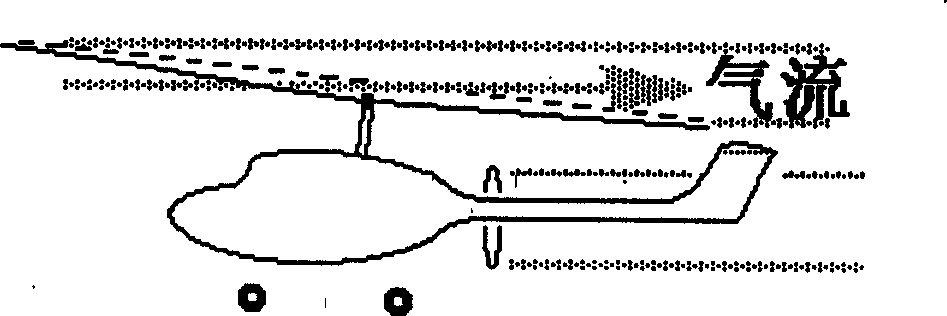

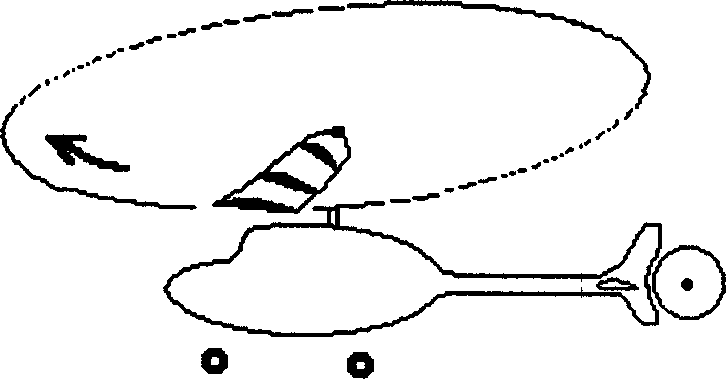

Embodiment 1

[0104] See Fig. 10,11,12,13-2, a kind of novel rotorcraft of intersecting double-rotor aerodynamic structure, it comprises fuselage 5, conventional helicopter power system, the main shaft 2 of fuselage upper part and the horizontal drive propeller 3 of rotorcraft, Drive clutch 15, empennage 4 etc. horizontally. The output end of the conventional helicopter power system is the main shaft 2, the upper end of the main shaft 2 is connected to the rotor 1, and the rotor 1 adopts a twist pitch propeller, which can be adjusted from positive pitch and negative twist to negative pitch and positive twist; the twist pitch propeller is as follows: Figure 13-2 Shown, be made up of variable torsion paddle 43, paddle shaft 26, adjustment bar 27. Figure 12 As shown, this machine can utilize the engine 13 in the conventional helicopter power system to drive the rotor 1 with positive pitch on the upper end of the main shaft 2 through the output shaft 12 through the main clutch 14 and the fina...

Embodiment 2

[0110] See Figure 16-1 , 16-2 , 17, 18, 19, 20, the above-mentioned aerodynamic variable torsion propeller, its blade tip 43b is additionally provided with an auxiliary wing, and its auxiliary wing is an aerodynamic variable torsion propeller using tip flaps, the aerodynamic variable torsion propeller Compared with "Example 1", there are more variable torque groups, and other parts are the same as "Example 1".

[0111] The auxiliary wing uses the aerodynamic twist propeller of the blade tip flap. The purpose is: 1. When it is working in the cruising state, it can control the lift of the blade tip more accurately, and the torque generated by the lift force is smaller than the twisting of the blade. degree (see Figure 17 shown in B' in). 2. During power vertical take-off and landing, the blade tip flaps added to the blade tip 43b should be used to increase the lift of the blade tip and obtain sufficient negative torque, so that the blade main part 43a is negatively twisted ...

Embodiment 3

[0115] See Figure 21 , the above-mentioned torsion pitch propeller, its auxiliary wing can use a kind of adaptive wing of prior art, in order to change the aerodynamic angle of attack of this adaptive wing. Other parts are the same as "Example 2".

[0116] The adaptive auxiliary wing can also well complete the same function as the blade tip flap in "Embodiment 2".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com