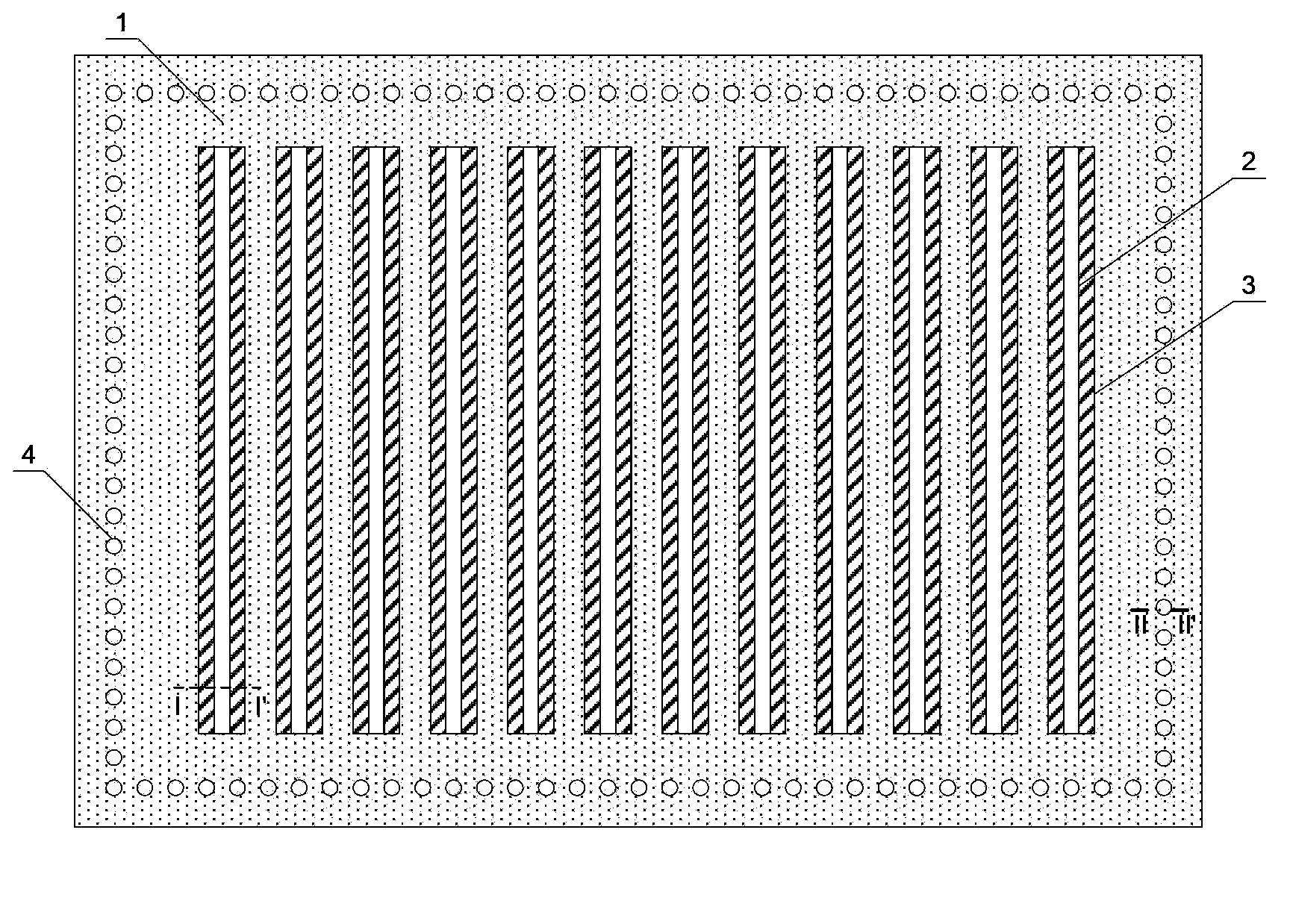

Mask plate

A mask and area technology, applied in the field of mask, can solve the problems of poor product quality, high cost, defectiveness, etc., and achieve the effect of reducing sag, reducing height and tight adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

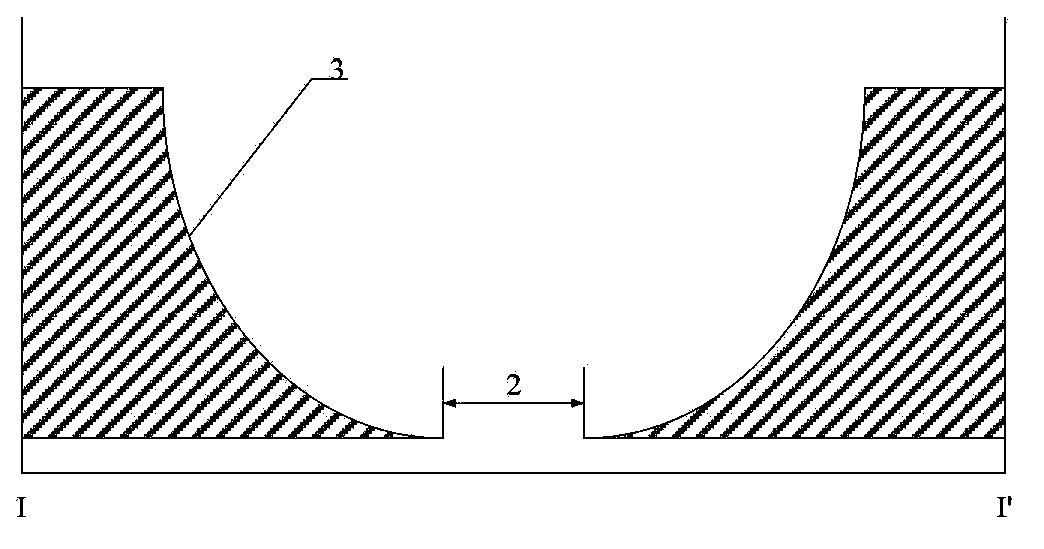

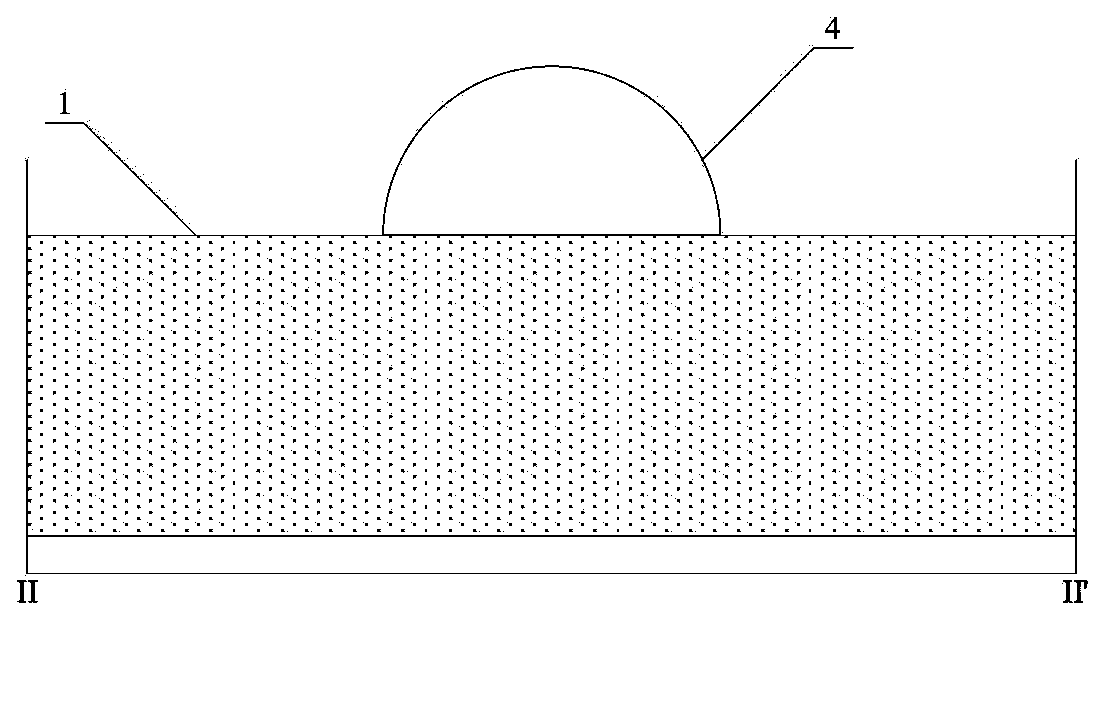

Method used

Image

Examples

Embodiment 2

[0031] The mask plate 1 in the second embodiment is made of iron-nickel alloy material, which includes: an opening part (or opening) 2'; a shielding part 3'; a solder joint 4; a first groove 6; and a second groove 5. Figure 8 shown as Figure 4 Schematic diagram of the cross-section of the structure of Ⅳ-Ⅳ′. combine Figure 7 and Figure 8 It can be seen that the second groove 5 is arranged on the side of the mask 1 facing away from the substrate, and it is arranged at the welding spot 4 on the edge of the mask 1 , and the welding spot 4 is located in the second groove 5 . Described second groove 5 can accommodate one or more solder joints, and its short side length is slightly greater than the diameter of solder joint 4, and its long side length is greater than the sum of one or more solder joint 4 diameters, and its depth is greater than the diameter of solder joint 4. The height is generally in the range of 10um-20um, preferably 15um. The existence of the second groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com