Tire-moved-type construction waste treatment device

A technology for construction waste and processing equipment, which is applied in construction waste recycling, recycling technology, and solid waste removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

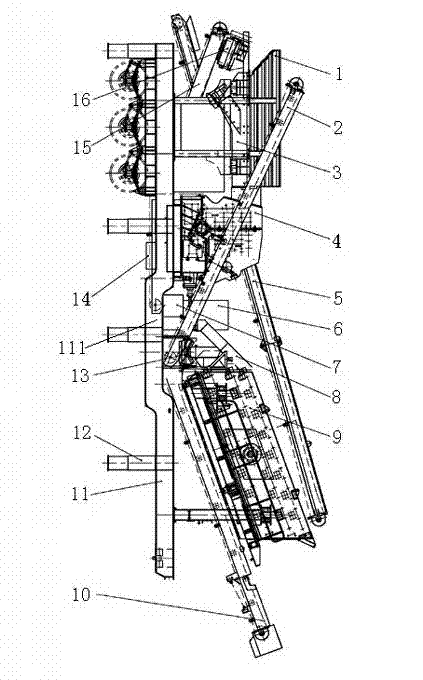

[0016] Embodiment 1 of the tire mobile construction waste disposal equipment of the present invention, as figure 1 As shown, it includes hydraulic outriggers 12, a vehicle frame 11 with a tire-type walking device, and the vehicle frame 11 is sequentially provided with a feeding device, a special separation and crushing equipment 4 for construction waste, and a vibrating device installed obliquely. Sieve 9, the feeding device includes a raw material bin 1 and a vibrating feeder 3, the outlet of the raw material bin 1 is connected to the inlet of the vibrating feeder 3, and the outlet of the vibrating feeder 3 is connected to the inlet of the special separation and crushing equipment 4 for construction waste Between the special separation and crushing equipment 4 for construction waste and the vibrating screen 9, there are successively provided a first discharge belt conveyor 15 that tilts upward toward the direction close to the feeding device, and a second discharge belt convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com