Process for manufacturing multi-layered thin film by dry vacuum vapor deposition

A vapor deposition, multi-layer thin-film technology, applied in superimposed layer plating, vacuum evaporation plating, semiconductor/solid-state device manufacturing, etc., can solve problems such as the inability to achieve the unique characteristics of the matrix, increased production time, and high production costs. Achieve beautiful and luxurious visual design, eliminate or reduce environmental pollution, and ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

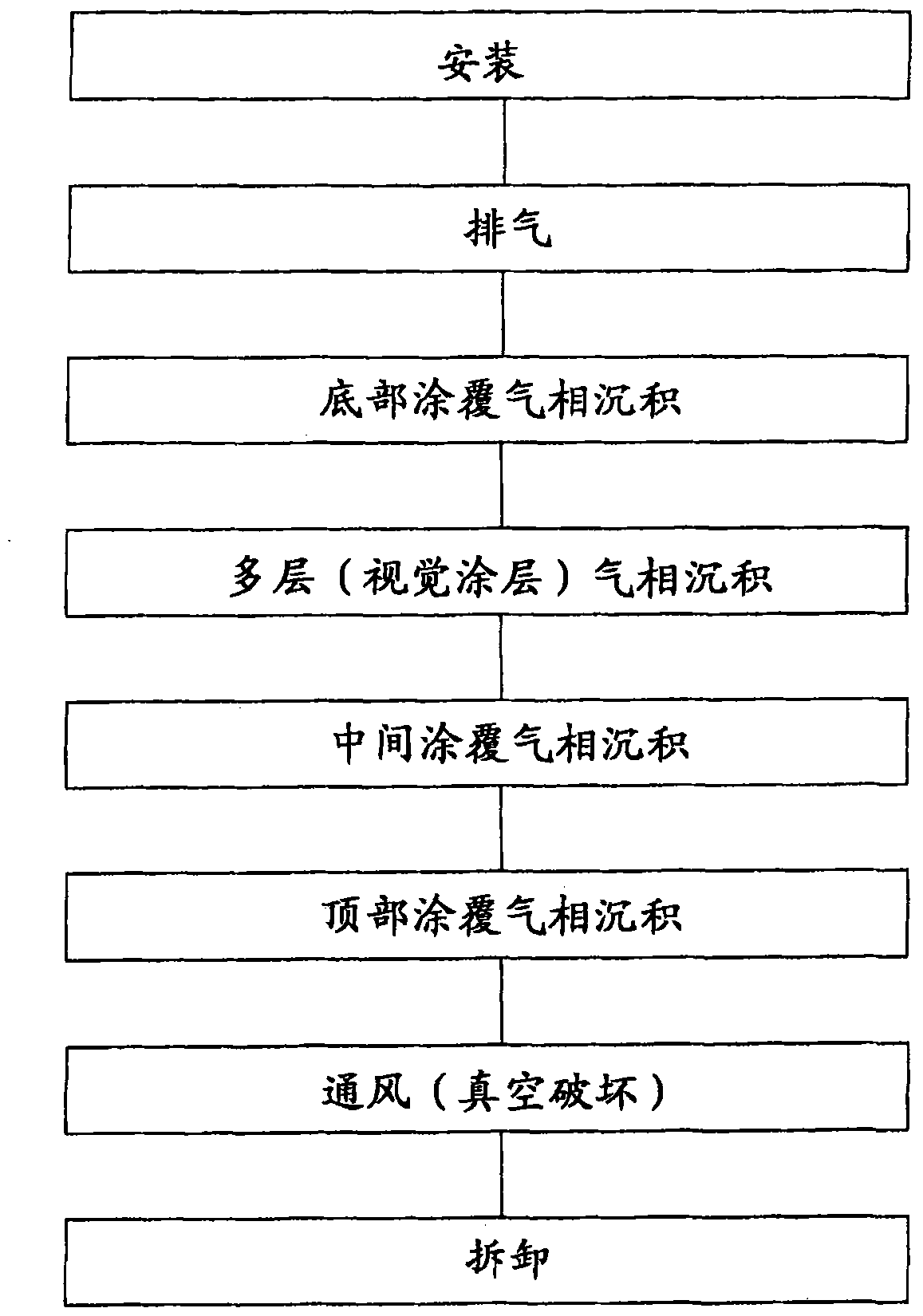

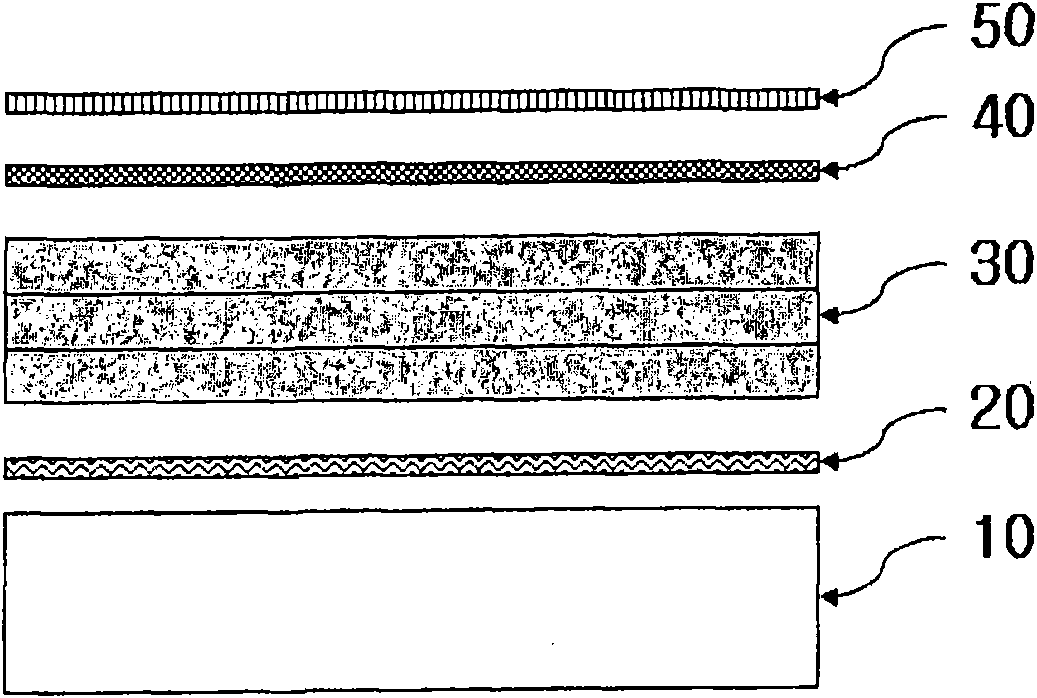

[0041] Compared with a conventional coating provided by a wet method, the vacuum vapor deposition method for producing a thin film of the present invention is characterized in that the coating is formed by a dry method in a vacuum vapor deposition apparatus. Conventional coatings currently provided by wet methods may include, for example, UV (ultraviolet) hardening type coatings, base coats for improving the adhesion strength between Layer coat of top coat.

[0042] In the vacuum vapor deposition method (dry method) of the present invention, the chemical reagents for forming each thin film layer are used to provide a stable single-layer or multi-layer coating in a vacuum vapor deposition device by an ultra-thin coating method, preferably using Vector as described in Korean Patent Application No. 10-2007-0075000.

[0043] Suitable substrates to which the film manufacturing method of the present invention can be applied include, but are not limited to, casings, windows, window-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com