Horizontal well leakage prevention double-layer tubing isolation circulation mechanism

A technology of double-layer oil pipe and circulation mechanism, which is applied in the direction of drilling pipe, casing, drilling equipment, etc., can solve the problems of reducing the working efficiency of sand flushing fluid, reducing the oil production capacity of the formation, formation pollution, etc., and achieves obvious leakage prevention function, Eliminate formation leakage, high efficiency and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in combination with specific embodiments.

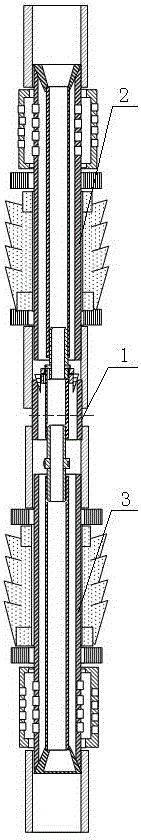

[0017] see figure 1 , the horizontal well leakage prevention double-layer oil pipe isolation circulation mechanism, including two identical double-layer oil pipe isolation steering joints connected through the double-layer oil pipe string structure, which are respectively the upper double-layer oil pipe isolation steering joint 2 and the lower double-layer oil pipe isolation steering joint Connector 3;

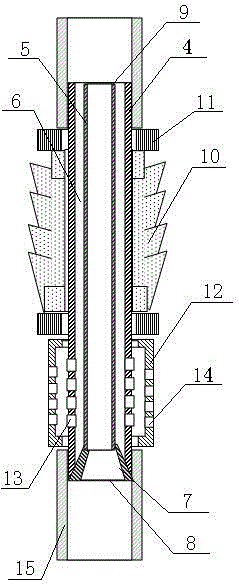

[0018] see figure 2 , the double-layer oil pipe isolation steering joint includes outer pipe 4, inner pipe 5 and oil pipe collars of different pipe diameters coaxially sleeved, and a double-layer oil pipe annulus 6 is formed between the outer pipe 4 and the inner pipe 5, and the double-layer oil pipe isolation The two ends of the outer wall of the outer pipe of the steering joint are respectively provided with oil pipe collars; the double-layer oil pipe annulus 6 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com