Pushing telescopic self-locking device and method for reducing formation loss caused by shield tail clearance

A technology of self-locking device and shield tail clearance, applied in underground chambers, shaft equipment, earthwork drilling and mining, etc., can solve problems such as formation deformation, achieve good surface deformation, control surface deformation, and avoid formation deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

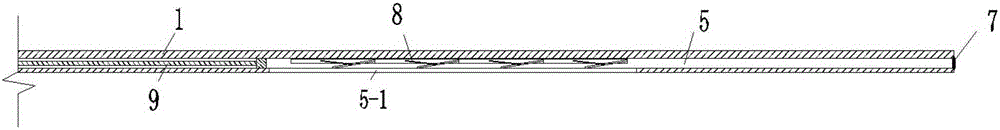

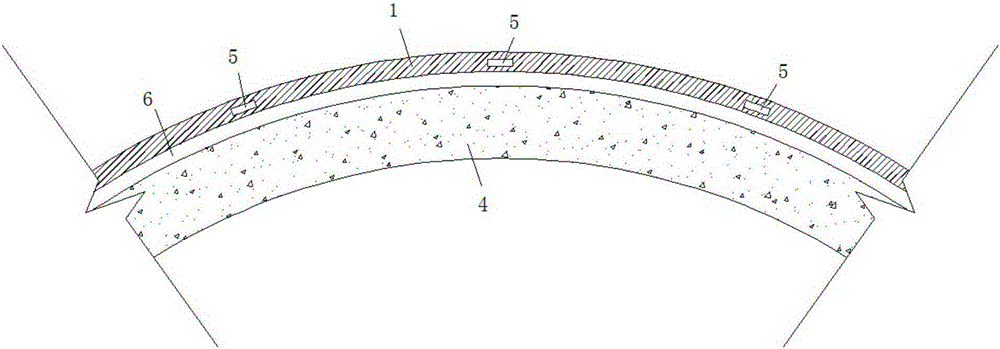

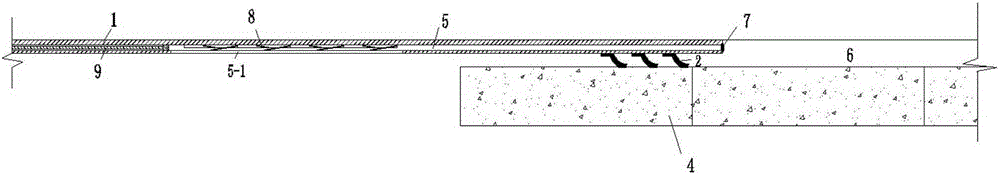

[0034] like figure 1 As shown, the push telescopic self-locking device for reducing formation loss caused by shield tail clearance includes setting a concealed compartment box 5 inside the shield tail steel shield of the shield machine, and a telescopic self-locking steel frame is placed in the concealed compartment box. It includes a concealed box body 5, an automatic isolation device 7, a telescopic self-locking steel frame 8, and a push piston 9. One side of the concealed compartment 5 is provided with an automatic isolating device 7, and the automatic isolating device 7 plays the role of preventing external groundwater, soil and grouting liquid from entering the concealed compartment, and the other side of the concealed compartment 5 is provided with Pushing the piston 9, the hidden grid box 5 is provided with an opening 5-1 for the telescopic self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com