Shallow buried soil shield construction method

A construction method and technology of shallow soil covering, which are applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve problems such as affecting the quality of the formed tunnel, the collapse of the face, and the leakage of water and slurry in the joints of the segments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] A construction method for shield tunneling with shallow covering soil, comprising the following steps:

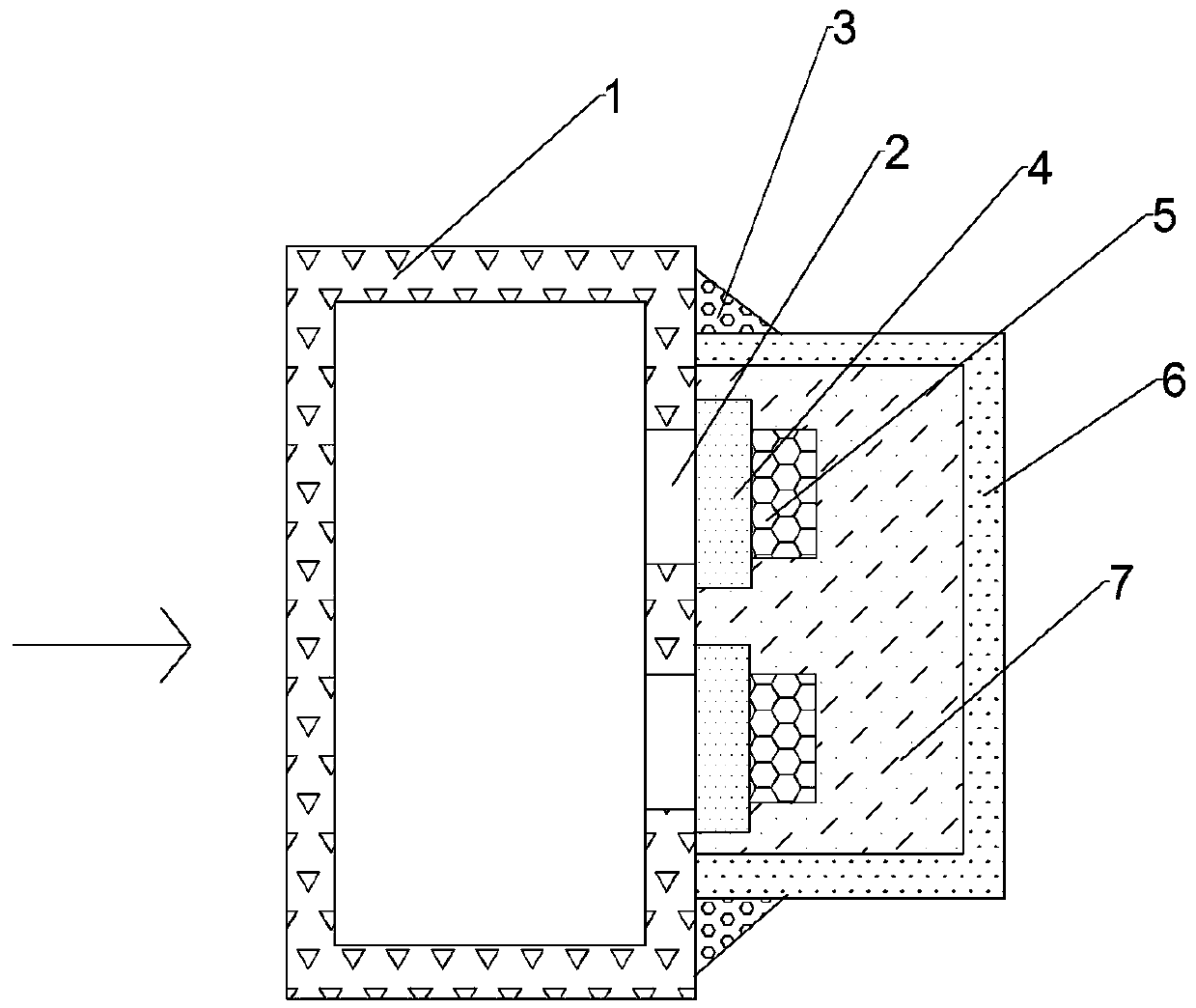

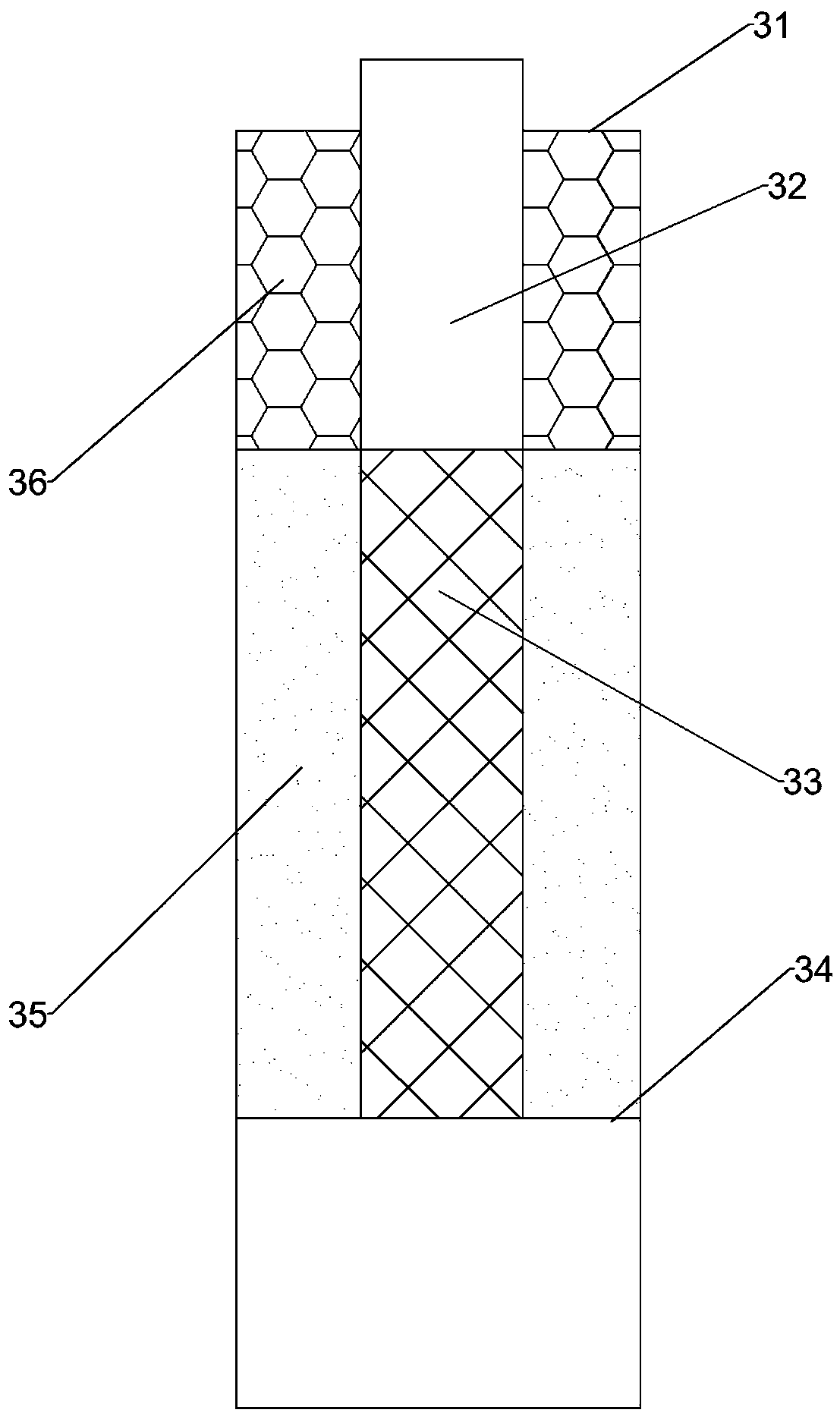

[0044] 1) Construction of the launch shaft: The launch shaft of the shield machine is constructed by the open cut and reverse method. The foundation pit enclosure structure 1 of the launch shaft adopts a 1200mm thick ground connecting wall, and six inclined concrete supports are vertically arranged, and a temporary neutral column is set in the middle. The central column adopts a 460mm×460mm lattice column; a Φ1200mm bored pile is arranged under the temporary central column;

[0045] 2) Reinforcement and precipitation of the initial section: the reinforcement of the initial section includes the reinforcement of the end of the initial section and the reinforcement of the ground; and the construction of the dewatering well after the reinforcement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com