Shield machine capable of three-dimensional grouting

A shield machine and grouting technology, which is used in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of soil stratum loss around the front soil shield, so as to reduce stratum loss, ground subsidence, and grouting effects. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

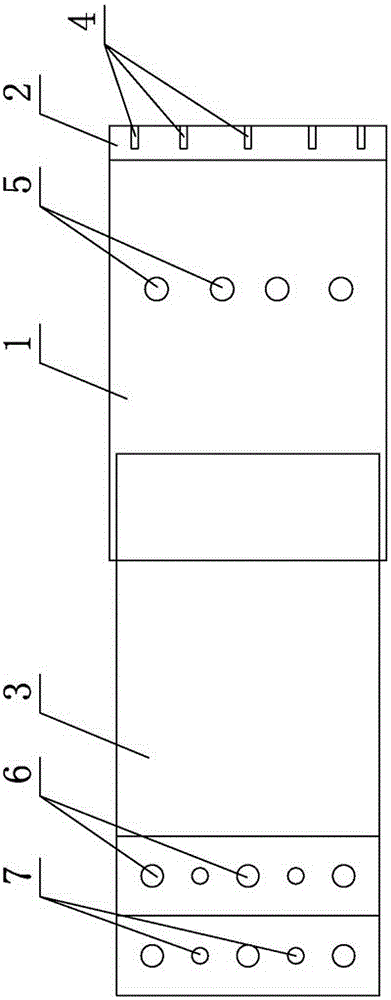

[0014] Such as figure 1 As shown, this embodiment includes a shield body 1 , a shield cutter head 2 installed on the front end of the shield body, and a group of segments 3 connected as a whole in the shield body.

[0015] A circle of advanced grouting holes 4 is uniformly arranged on the edge of the shield cutter head 2 (in this example, the number of advanced grouting holes is sixteen), and the grouting direction of each advanced grouting hole 4 is parallel to the axis of the shield body 1 Arrangement; when the incision has roof fall and collapse, the grouting fluid can be pressed to the front soil through the advance grouting hole 4, and the soil in front of the shield cutter head 2 can be reinforced and improved.

[0016] A circle of shield grouting holes 5 is evenly arranged on the side wall of the middle part of the shield body 1 (in this example, the number of shield body grouting holes is eight), and the axes of each shield body grouting holes 5 intersect with the shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com