A pile recovery method of steel pipe slope protection piles

A recovery method, technology of slope protection piles, applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., to achieve the effect of smooth pulling out process, reducing bonding resistance, and reducing formation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

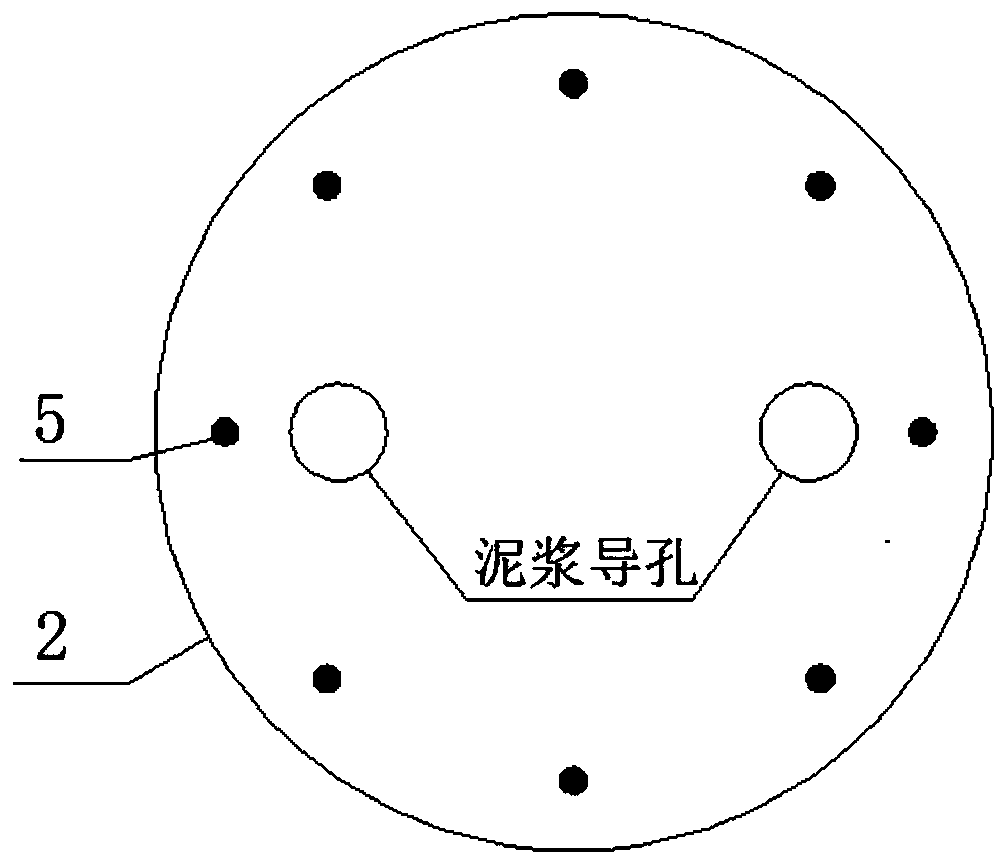

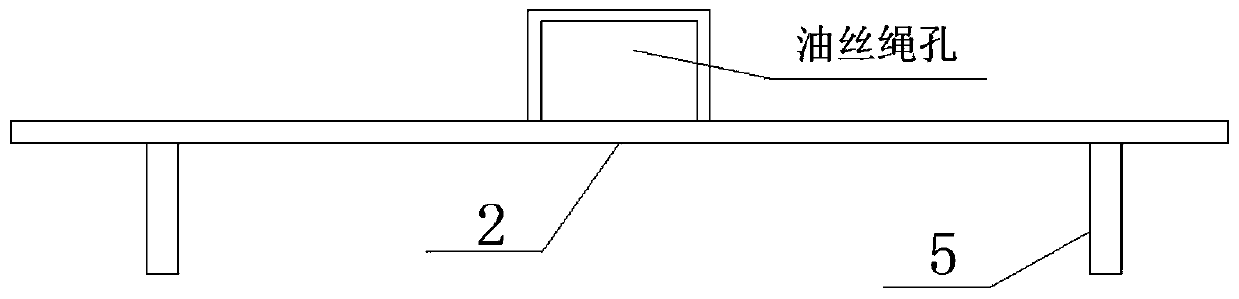

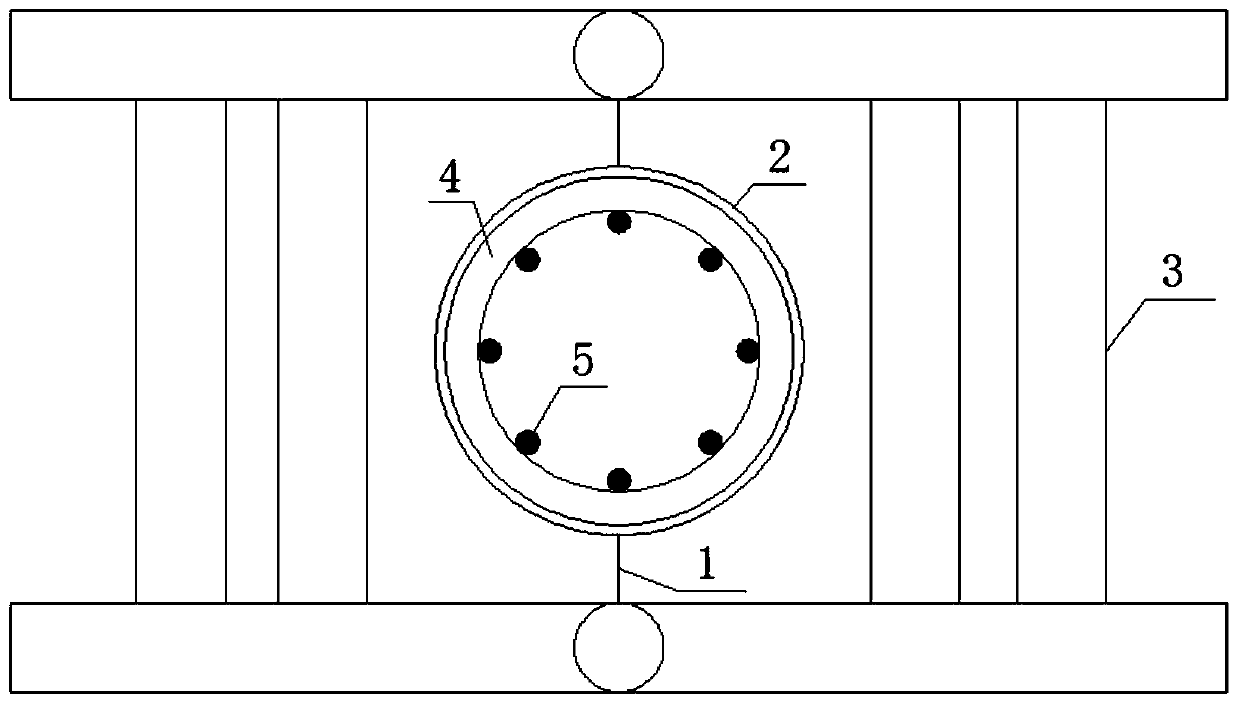

[0021] like Figure 1-7 Shown, a pile recovery method of steel pipe slope protection piles, the method adopts reverse circulation drilling rig mud protection wall forming method to drill pile holes at the line position of steel pipe slope protection piles, the pile hole diameter is 900mm, and then oil wire rope (1) Fix the steel substrate (2) on the steel substrate fixing frame (3), place the retaining pipe (4) on the steel substrate (2) and clamp it with the limit steel bar (5). The material of the retaining pipe (4) used in a poor construction site is concrete material; the material of the retaining pipe (4) selected in a construction site with better ground soil conditions is a PVC material.

[0022] Loosen the oil rope (1) and put the retaining pipe (4) into the pile hole, and lengthen the retaining pipe (4) section by section at the pile hole until the steel substrate (2) reaches the bottom of the pile hole. The outer parts of the steel pipe slope protection piles (6) ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com